Guard fence device of raking machine

A technology of guardrail and raking machine, which is applied in the directions of transportation and packaging, earthwork drilling, underground transportation, etc., can solve the problems of lack of protection, high impact force of bombing, hidden dangers in safety production, etc., and prevent rope breakage. The effects of damage, reduction of stress and deformation, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

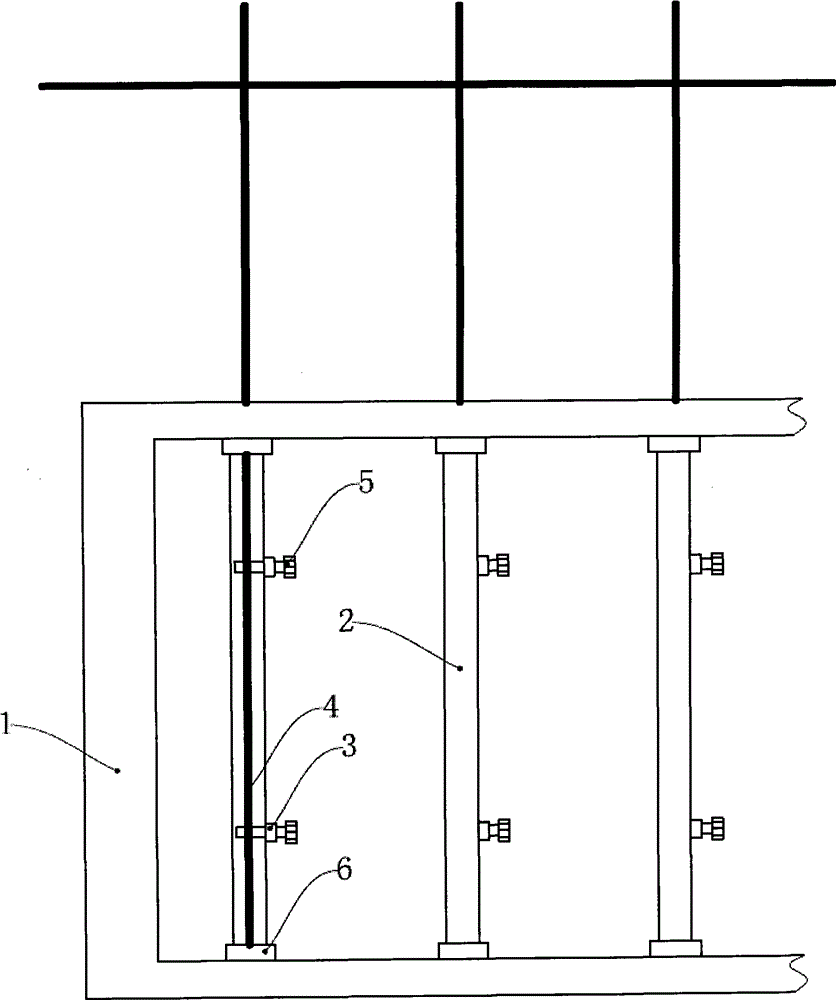

[0014] see figure 1 , a gangue machine guardrail device, comprising a frame 1 welded by angle steel, characterized in that, a plurality of steel pipes 2 are distributed at equal intervals in the frame 1, and each steel pipe 2 is provided with two equal intervals up and down Fixing wire holes 3; each steel pipe 2 penetrates an anchor rope 4, and the anchor rope 4 is tightened and fixed by bolts 5 through the fixing wire holes 3, and the anchor rope 4 extends to the Describe steel pipe 2 outside.

[0015] In this embodiment, the connecting part of the steel pipe 2 and the frame 1 is provided with a thickened steel plate 6 .

[0016] In the present invention, two fixed wire holes 3 are opened at equal intervals up and down on the steel pipe 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com