Full-metal high-temperature-resistant screw pump

A high temperature resistant, screw pump technology, used in pumps, pump components, rotary piston pumps, etc., can solve the problems of short working life, leakage, and the inability to produce all-metal screw pumps, and achieve low operating noise and floor space. Less, solve the effect of short working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

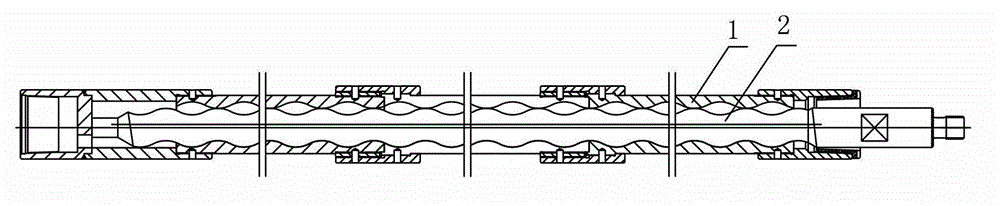

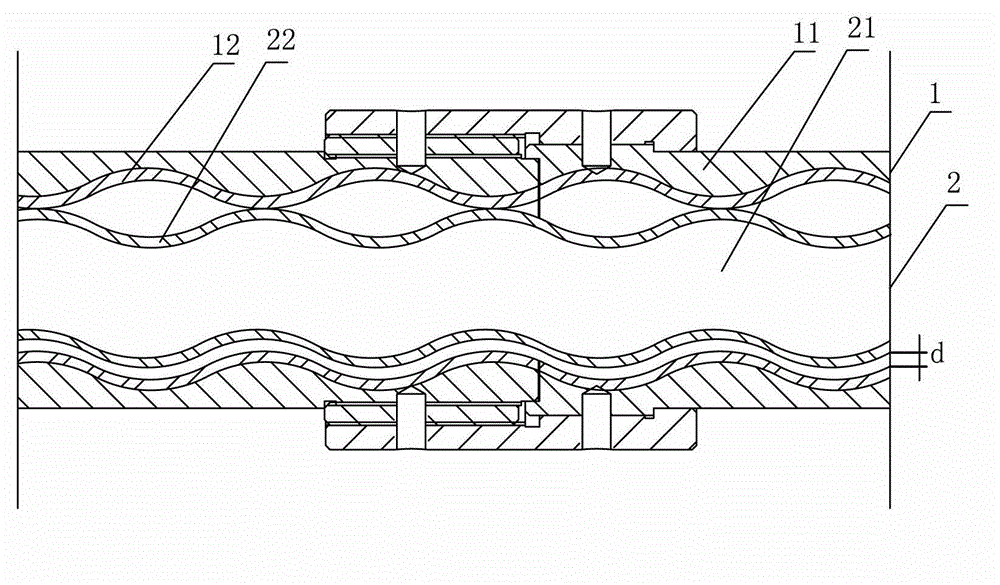

[0013] Embodiment 1: As shown in the figure, an all-metal high-temperature-resistant screw pump includes a metal stator 1 and a metal rotor 2. The inner surface of the metal stator 1 and the outer surface of the metal rotor 2 are in clearance fit, and the inner surface of the metal stator 1 is in contact with the metal rotor 2. The gap distance on the outer surface of the rotor 2 is 0.01 mm. The metal stator 1 includes a stator metal base 11 and a hard material permeation layer 12 arranged on the inner surface of the stator metal base 11. The metal rotor 2 includes a rotor metal base 21 and a metal base 21 arranged on the rotor metal base. The chromium-coated layer 22 on the outer surface of 21, the hard material infiltrated layer 12 is a tungsten carbide layer with a Hastelloy hardness of HV1100, the thickness of the hard material infiltrated layer 12 is 4 microns, and the Hastelloy hardness of the chromium-coated layer 22 is HV900 , the thickness of the chrome-coated layer 22...

Embodiment 2

[0014] Embodiment 2: As shown in the figure, an all-metal high-temperature-resistant screw pump includes a metal stator 1 and a metal rotor 2. The inner surface of the metal stator 1 and the outer surface of the metal rotor 2 are in clearance fit, and the inner surface of the metal stator 1 is in contact with the metal rotor 2. The gap distance on the outer surface of the rotor 2 is 0.4 mm. The metal stator 1 includes a stator metal base 11 and a hard material permeation layer 12 arranged on the inner surface of the stator metal base 11. The metal rotor 2 includes a rotor metal base 21 and a metal base 21 arranged on the rotor metal base. The chrome-coated layer 22 on the outer surface of 21, the hard material infiltrated layer 12 is a tungsten carbide layer with a Hastelloy hardness of HV1200, the thickness of the hard material infiltrated layer 12 is 10 microns, and the Hastelloy hardness of the chromium-coated layer 22 is HV900 , the thickness of the chrome-coated layer 22 i...

Embodiment 3

[0015] Embodiment 3: As shown in the figure, an all-metal high-temperature-resistant screw pump includes a metal stator 1 and a metal rotor 2, the inner surface of the metal stator 1 and the outer surface of the metal rotor 2 are in clearance fit, and the inner surface of the metal stator 1 is in contact with the metal rotor 2. The gap distance on the outer surface of the rotor 2 is 0.2 mm. The metal stator 1 includes a stator metal base 11 and a hard material permeation layer 12 arranged on the inner surface of the stator metal base 11. The metal rotor 2 includes a rotor metal base 21 and a metal base 21 arranged on the rotor metal base. The chrome-coated layer 22 on the outer surface of 21, the hard material infiltrated layer 12 is a tungsten carbide layer with a Hastelloy hardness of HV1150, the thickness of the hard material infiltrated layer 12 is 15 microns, and the Hastelloy hardness of the chromium-coated layer 22 is HV900 , the thickness of the chrome-coated layer 22 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com