A spent fuel storage module

A spent fuel and fuel technology, applied in the direction of reactor fuel elements, reactors, greenhouse gas reduction, etc., can solve the problems of limited system cooling capacity, low inherent safety of the system, complex system, etc., to avoid desalination and purification, economical The effect of improving and improving the overall safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

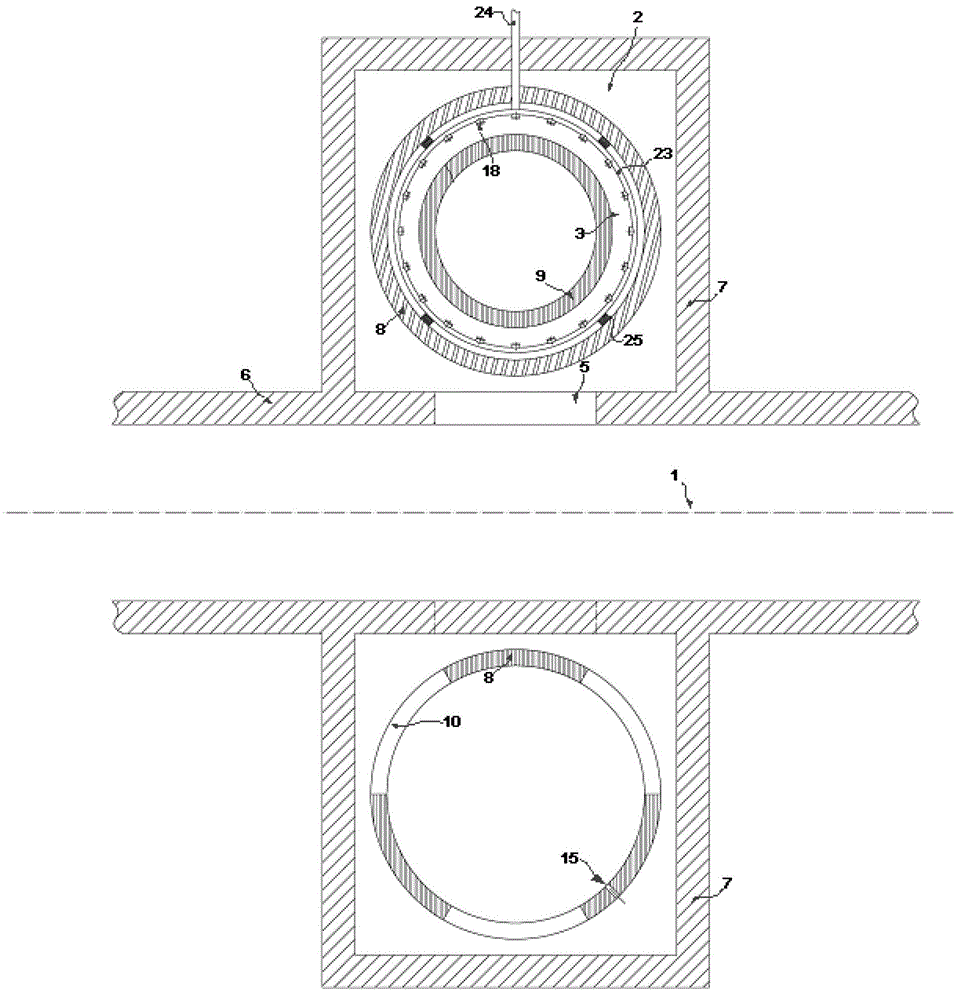

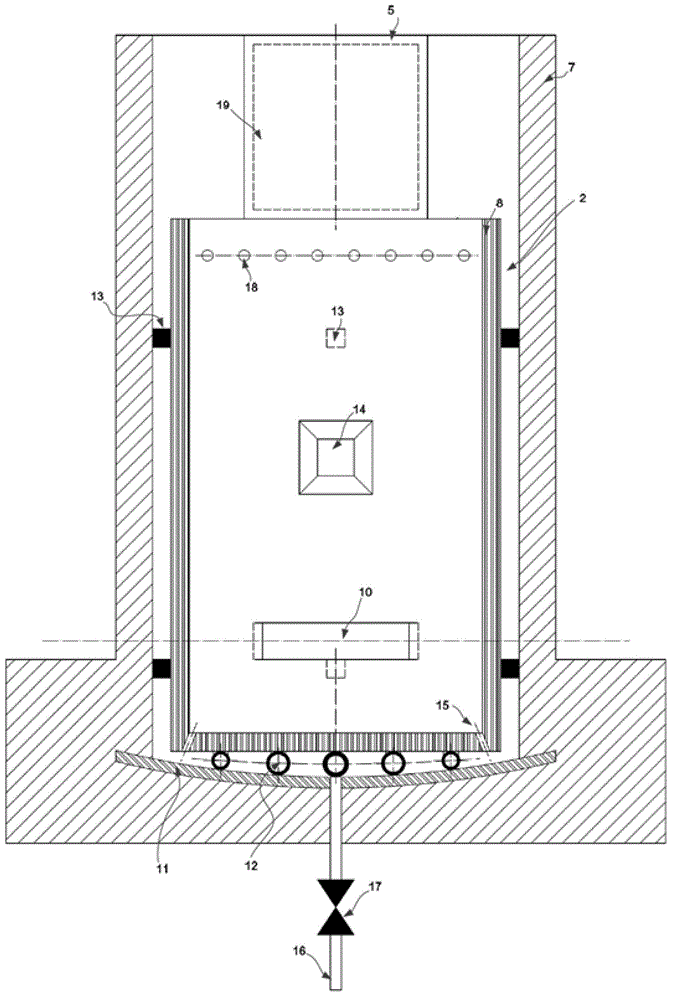

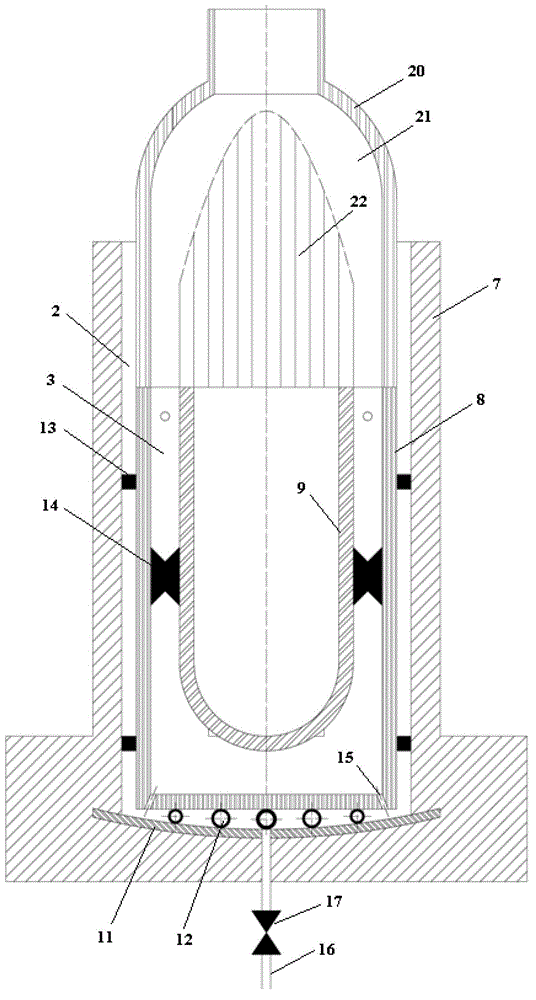

[0025] Such as figure 1 As shown, the spent fuel storage module provided by the present invention includes an intermediate container 8 disposed in the boundary of the storage module and a fuel container 9 disposed in the intermediate container 8, and the boundary of the storage module is composed of a concrete structure 7 of the storage module and a common channel wall 6, the spent fuel storage modules located on both sides of the common channel 1 communicate with the common channel 1 through the fuel inlet and outlet channels 5 provided on the wall 6 of the common channel. With this structural arrangement, the storage of spent fuel is modularized and unitized. Considering the high radioactivity of spent fuel, the concrete structure body 7 of the storage module and the wall body 6 of the public channel are shielded by heavy concrete, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com