Pipe joint cutting device

A technology of cutting device and pipe joint, applied in the field of pipe joint cutting device, can solve the problems of easy damage to drilling machine equipment, low production efficiency, etc., and achieve the effects of being convenient for large-scale use, high processing efficiency and good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

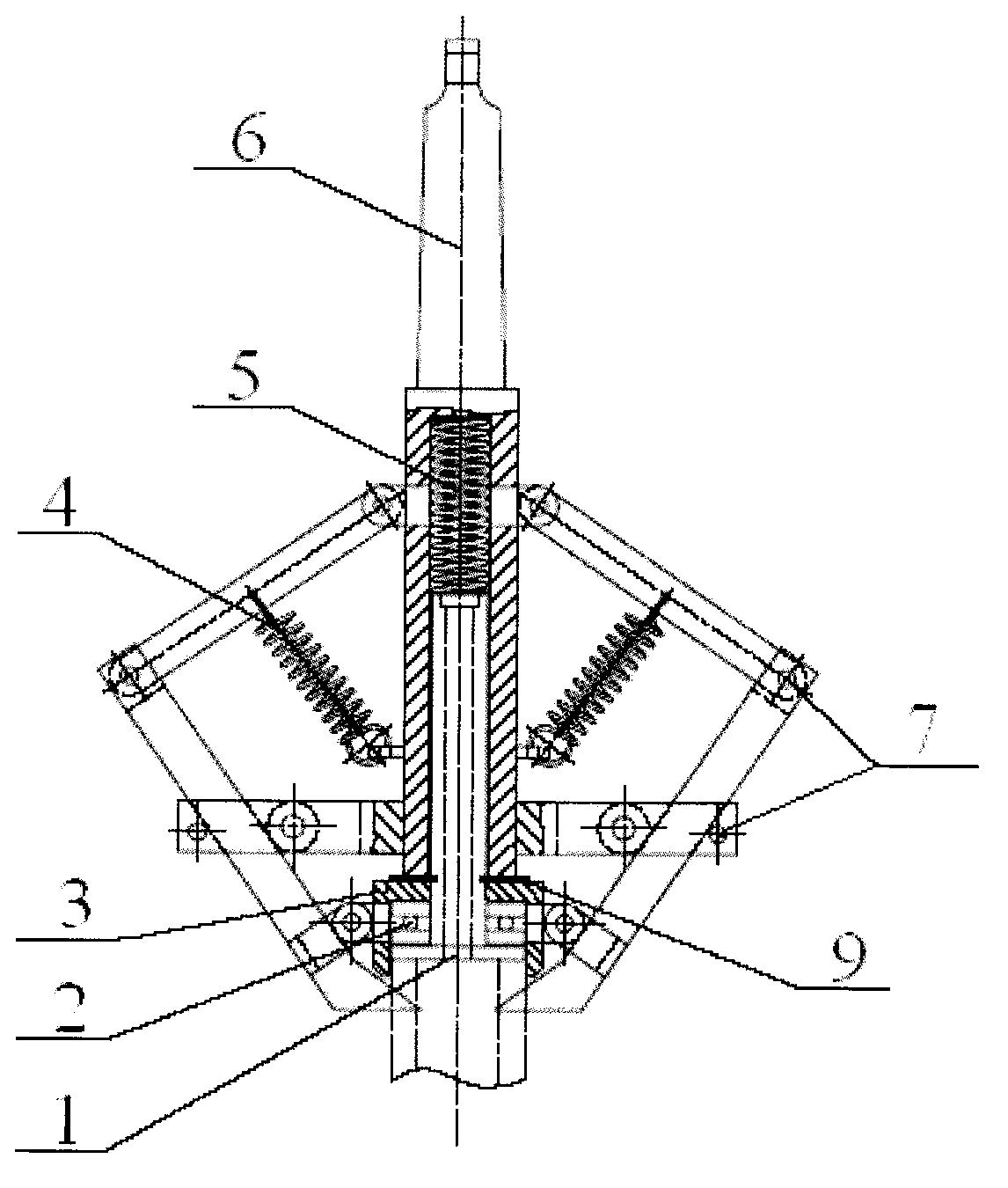

[0041] The present invention is a pipe joint cutting device, such as figure 1 Shown is a structural schematic diagram of a pipe joint cutting device. The contact device 1 passes through the capping device 3 and is connected with the lifting device 6 , the lifting device 6 is equipped with a tension spring 4 , and the lifting device 6 is equipped with a compression spring 5 .

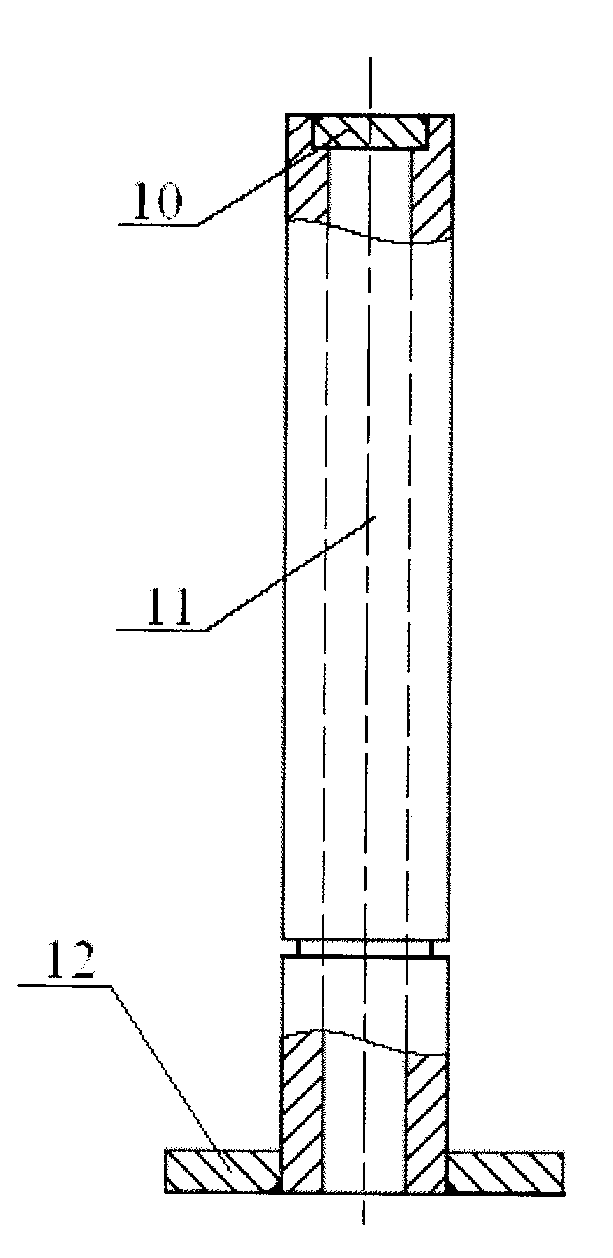

[0042] Such as figure 2 Shown is a schematic structural diagram of the contact device 1 . The contact device 1 includes a sealing plate 10, a top plate 12, and a sliding rod 11. The middle part of the sliding rod 11 is designed with a groove, and the top of the sliding rod 11 is embedded with the sealing plate 10, and is connected by welding, and the welding seam at the port is smoothed. The top plate 12 is aligned with the port at the bottom of the slide bar 11, and then connected by welding, and the weld seam is ground after welding.

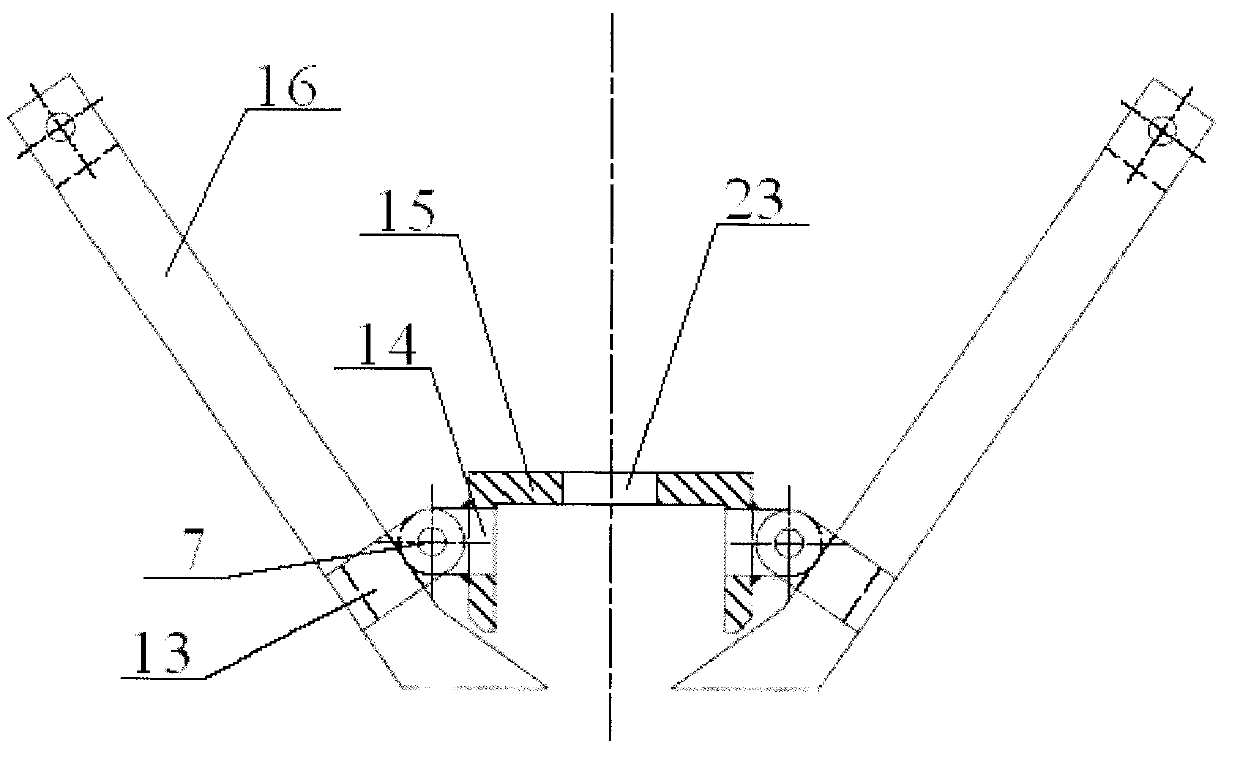

[0043] Such as image 3 Shown is a schematic structural view o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com