Automatic tightening machine for nut for car horn bracket

A horn bracket and tightening machine technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of large difference in tightening torque, wear of parts, and high cost, and achieve reliable tightening torque, good versatility, and meet the variety of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the description of the drawings and specific embodiments, but it is not intended to limit the scope of protection thereof.

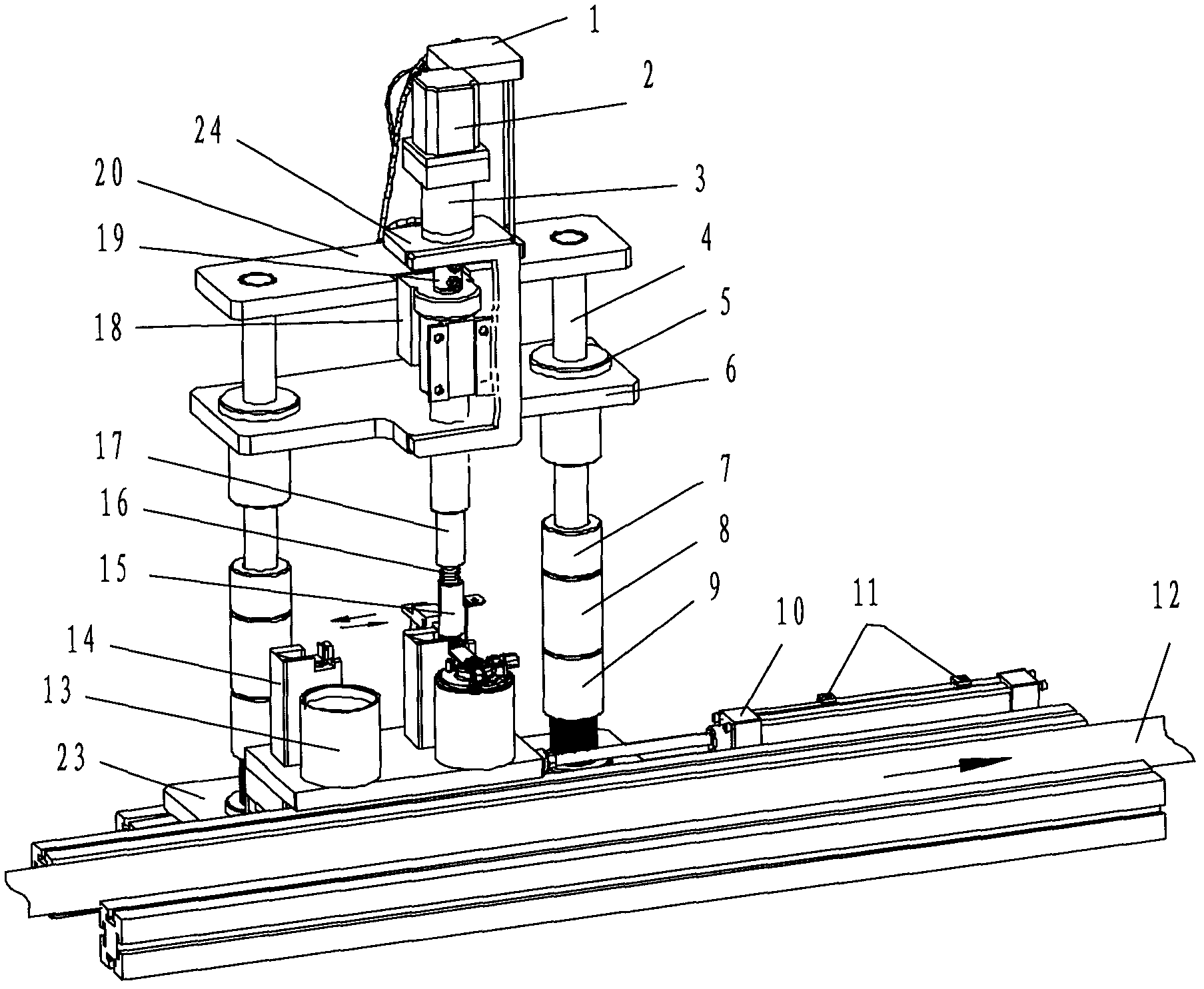

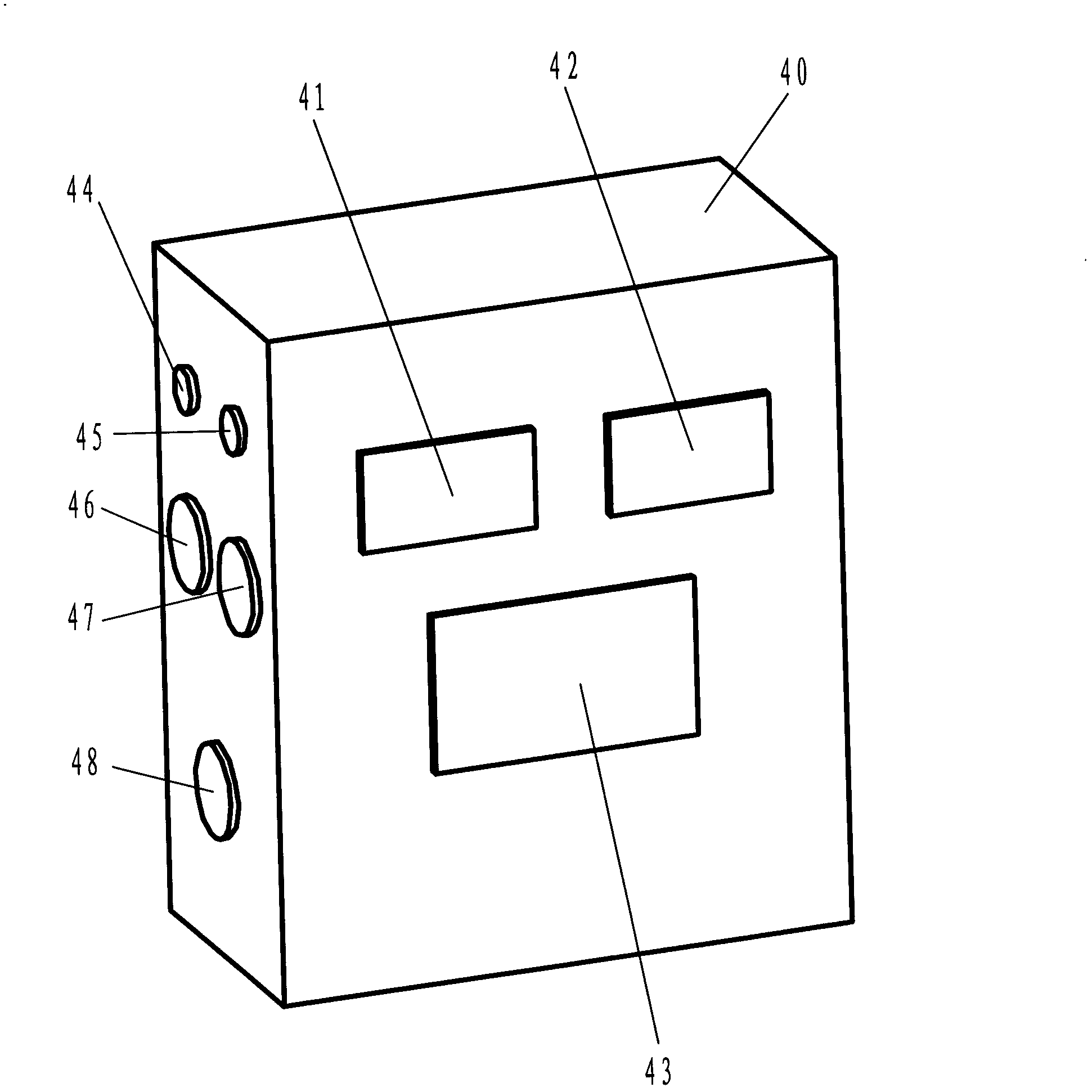

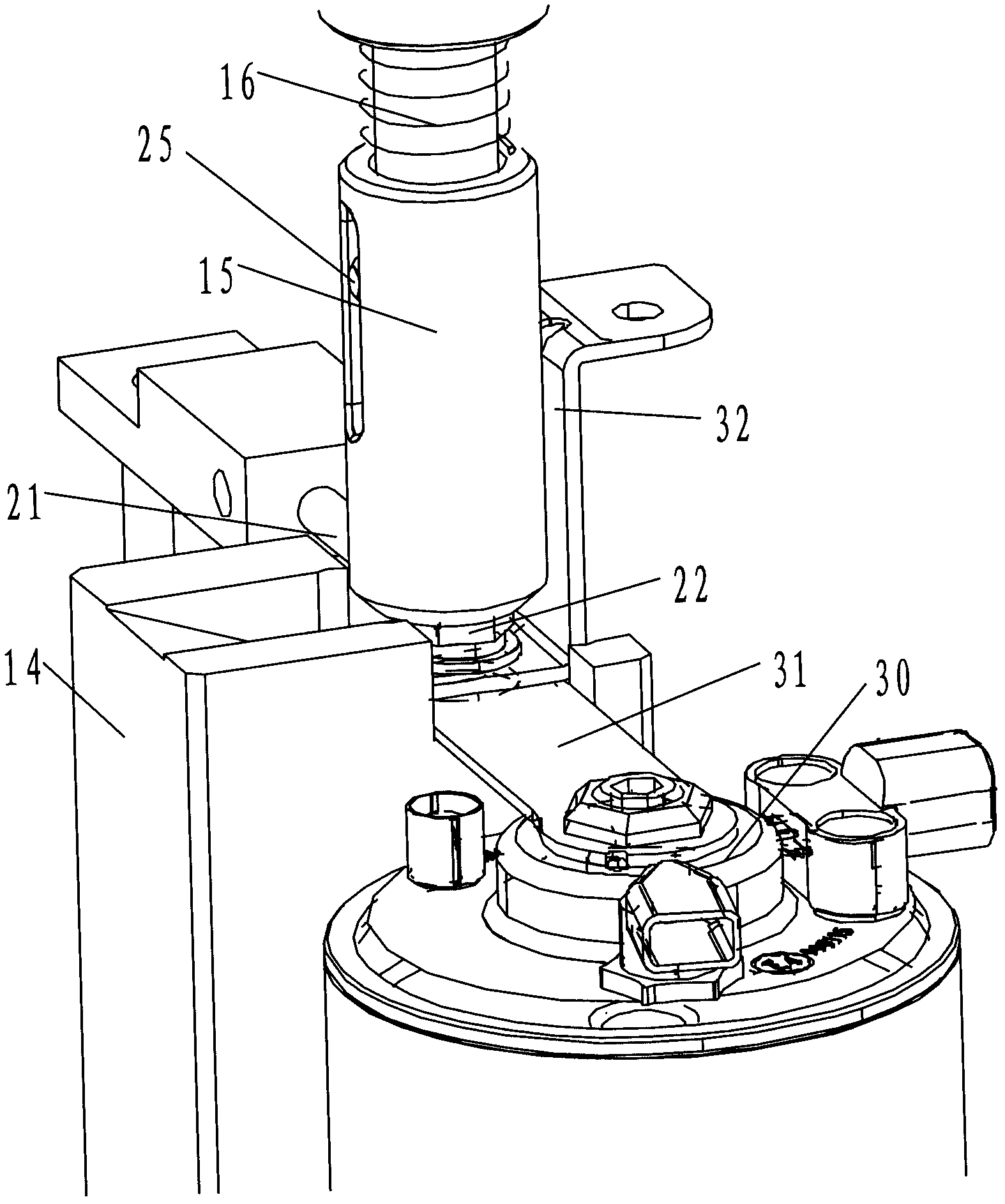

[0015] see figure 1 , figure 2 , an automatic tightening machine for automobile horn bracket nuts of the present invention, comprising a lifting cylinder 1, a servo driver 2, a torque sensor 3, a guide post 4, a guide sleeve 5, a movable template 6, a vibration damping pad 7, an upper limit sleeve 8, a lower limit Bit sleeve 9, cylinder with magnetic ring 10, magnetic sensor 11, speaker positioning cavity 13, clamp 14, connecting shaft sleeve 15, compression spring 16, output shaft 17, reducer 18, connecting sleeve 19, upper template 20, lower Formwork 23, mounting plate 24, positioning pin 25, photoelectric sensor 21, power distribution cabinet 40 is formed, and described guide post 4, guide sleeve 5, upper formwork 20, lower formwork 23 are formed into fixed formwork, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com