An antistatic transparent hardened film

A hardening film and anti-static technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of opacity, affecting the visual effect of products, affecting the transparency of hard coatings, etc., to achieve non-interference texture, superior total light transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

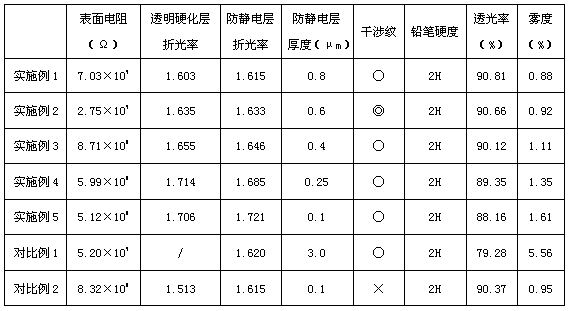

Examples

Embodiment 1

[0038] 1. Preparation of titanium dioxide dispersion:

[0039] 20 parts by weight of nano titanium dioxide and 80 parts by weight of butanone were mixed together, dispersed on a high-speed mixer for 30 minutes, then ball milled for 1 hour with a ball mill, and filtered to obtain titanium dioxide with an average particle size of 0.8 μm and a solid content of 20%. Dispersions.

[0040] 2. Preparation of coating material for transparent hardened layer

[0041] 6195-1009.6 parts by weight,

[0042] 1840.4 parts by weight,

[0043] 12.0 parts by weight of titanium dioxide dispersion,

[0044] Byk-3770.05 parts by weight,

[0045] Butanone 27.87 parts by weight,

[0046] Dissolve 9.6 parts by weight of aliphatic urethane acrylate prepolymer 6195-100 [Changxing Chemical; functionality 10] into 27.87 parts by weight of methyl ethyl ketone solvent, add 0.05 parts by weight of polyether-modified polydimethylsiloxane fluid Leveling agent BYK-377 [Bick Chemical], and add 0.40 parts ...

Embodiment 2

[0057] 1. Preparation of zirconia dispersion:

[0058] 20 parts by weight of nano zirconia and 80 parts by weight of butanone were mixed together, dispersed on a high-speed mixer for 30 minutes, then ball milled for 1.5 hours with a ball mill, and filtered to obtain a solid content of 20% and an average particle size of 0.6 μm. Zirconia dispersion.

[0059] 2. Preparation of coating material for transparent hardened layer

[0060] UXE10009.0 parts by weight,

[0061] 1840.4 parts by weight,

[0062] Zirconia dispersion 15.0 parts by weight,

[0063] Levaslip4320.05 parts by weight,

[0064] Butanone 25.5 parts by weight,

[0065] Dissolve 9.0 parts by weight of aliphatic urethane acrylate prepolymer UXE1000 [manufactured by Huayao Chemical (Wuxi) Co., Ltd., functionality 4] into 25.5 parts by weight of methyl ethyl ketone, add 0.05 parts by weight of polydimethylsiloxane Skeleton structure leveling agent Levaslip432 [manufactured by Deqian (Shanghai) Chemical Co., Ltd.],...

Embodiment 3

[0076] 1. Preparation of zinc sulfide dispersion:

[0077] 20 parts by weight of nano-zinc sulfide and 80 parts by weight of butanone were mixed together, dispersed on a high-speed mixer for 40 minutes, then ball milled for 1.5 hours with a ball mill, and filtered to obtain a solid content of 20% and an average particle size of 0.4 μm. Zinc sulfide dispersion.

[0078] 2. Preparation of coating material for transparent hardened layer

[0079] EM-24118.4 parts by weight,

[0080] 1840.4 parts by weight,

[0081] 18.0 parts by weight of zinc sulfide dispersion,

[0082] BYK-3770.05 parts by weight,

[0083] Butanone 23.13 parts by weight,

[0084]Dissolve 8.4 parts by weight of ethoxylated pentaerythritol tetraacrylate monomer EM-2411 [Changxing Chemical, functionality 4] into 23.13 parts by weight of methyl ethyl ketone solvent, add 0.05 parts by weight of polyether modified polydimethylsiloxane flow Leveling agent BYK-377 [Bick Chemical], and add 0.40 parts by weight of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com