Abutting joint method of transporting device

A boarding bridge and frame technology, applied to ground installations, transportation and packaging, aircraft parts, etc., can solve problems such as potential safety hazards, poor flexibility and sealing, easy damage to the fuselage shell, etc., to prevent overloading and good sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

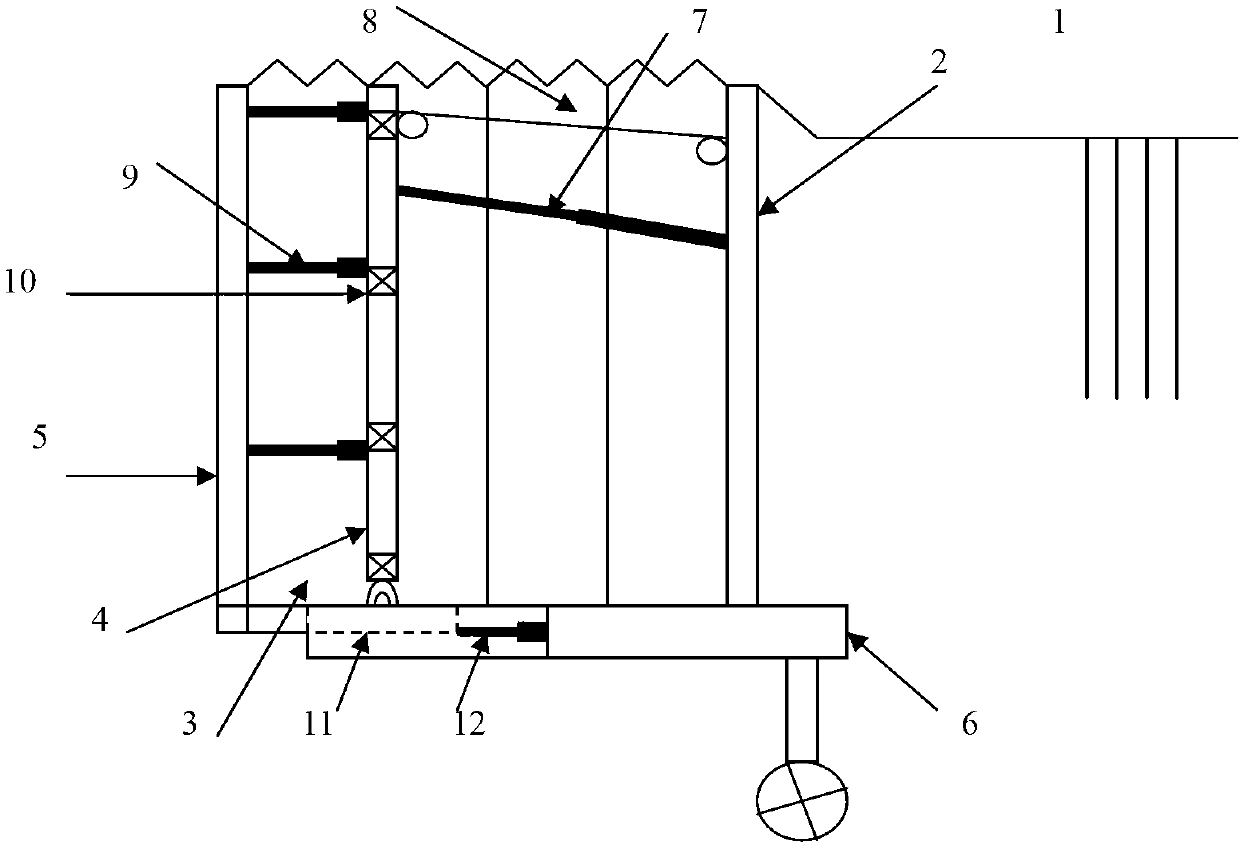

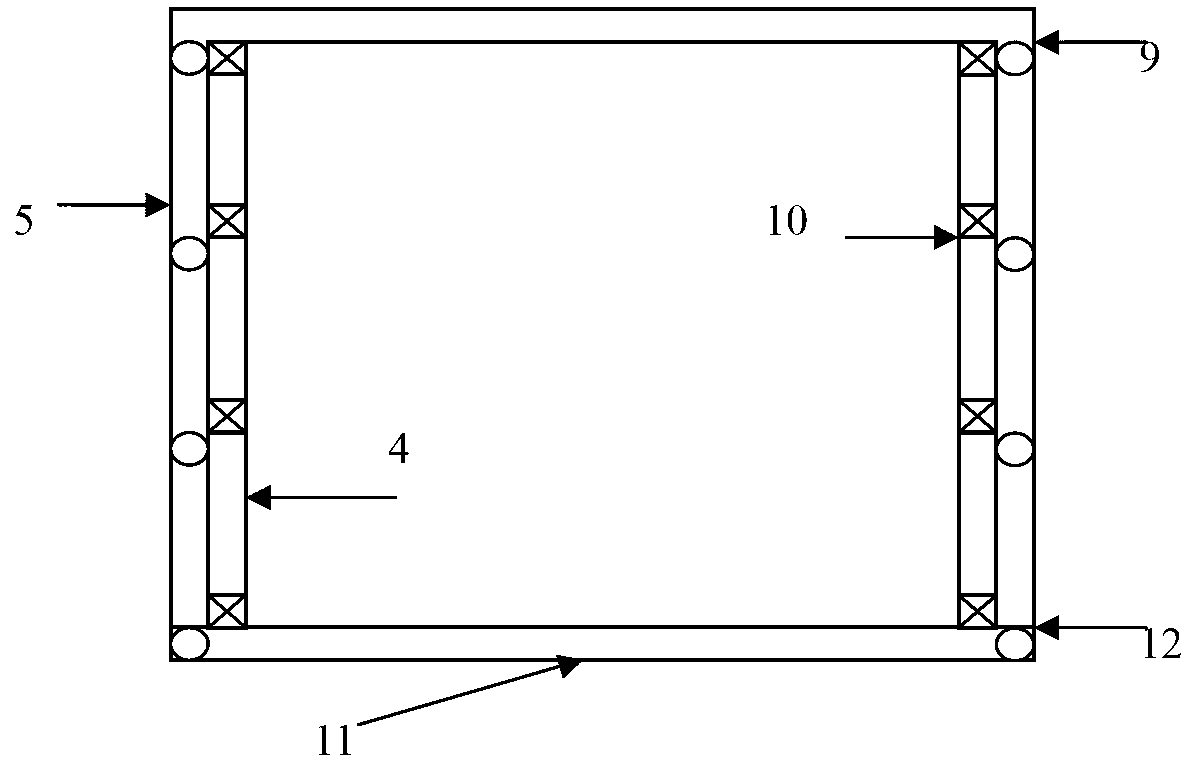

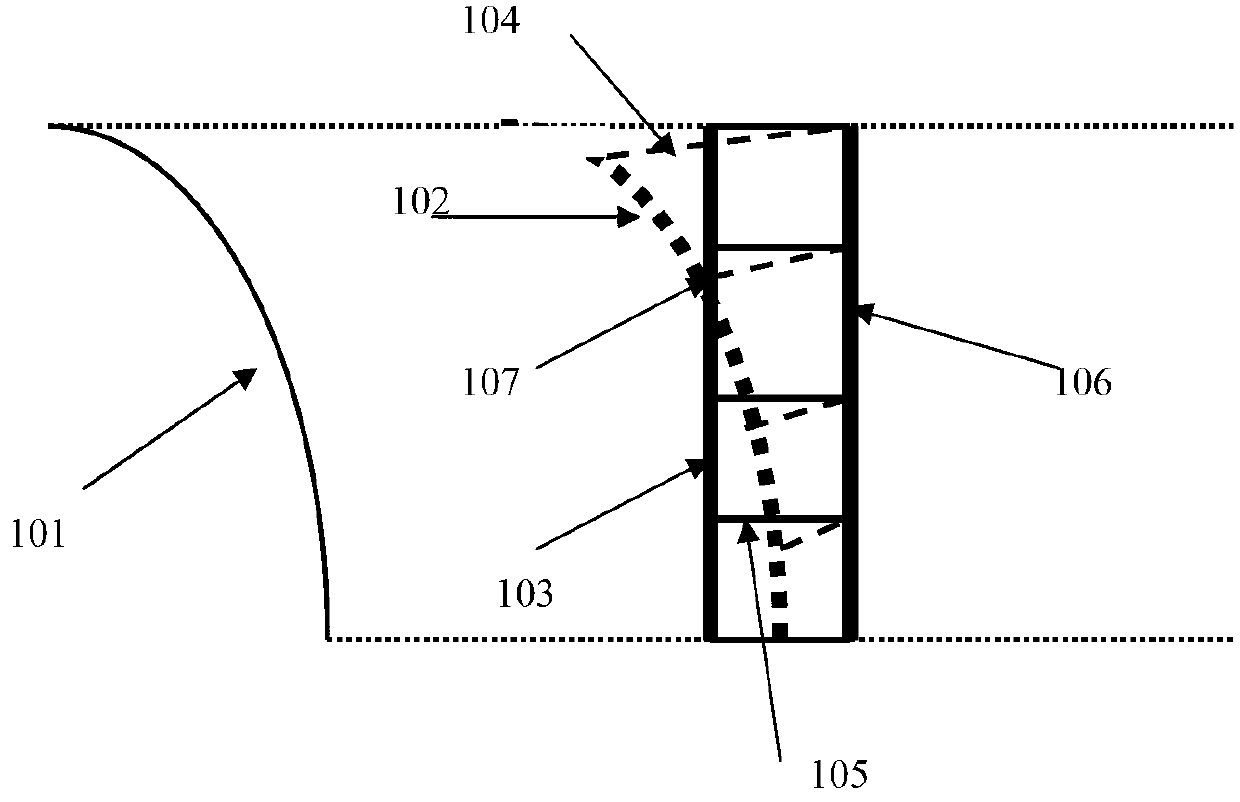

[0015] Refer to attached figure 1 , which partially shows a telescopic boarding bridge including rollers according to the present invention, which includes a bridge channel and an awning device 1, which includes a portal frame 2 and a docking frame 3, which is directly used In order to realize the docking of the canopy device 1 and the shell of the aircraft fuselage. The docking frame 3 includes a rigid frame 4 and a flexible frame 5 that will be in direct contact with the fuselage shell. The flexible frame 5 is made of flexible material, but the material has poor ductility, such as plastic. The flexible frame may further include cushioning materials, air cushions or elastically deformable tubes, etc. around the flexible frame. The canopy device further comprises a floor 6, wherein the floor is a retractable floor comprising a telescoping portion 11 by means of, for example, an actuator inside the floor, such as a hydraulic actuator. 12 to realize telescopic movement, the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com