Special elastic supporting piece of vibratory feeder

An elastic support and feeder technology, which is applied in vibrating conveyors, conveyors, transportation and packaging, etc., can solve the problems of poor stability in the vibration feeding process, high processing difficulty, complex structure, etc., to achieve easy installation, reduce production costs, Resolving structurally complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

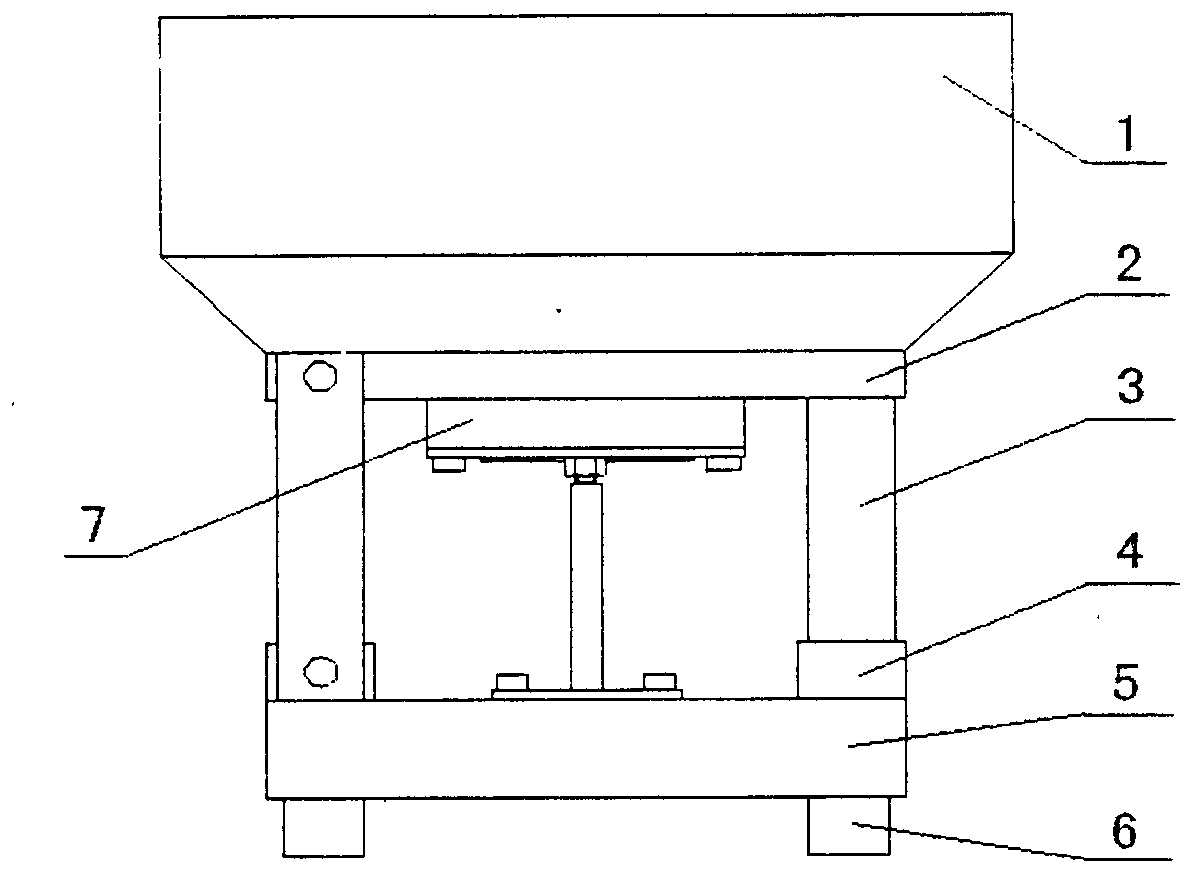

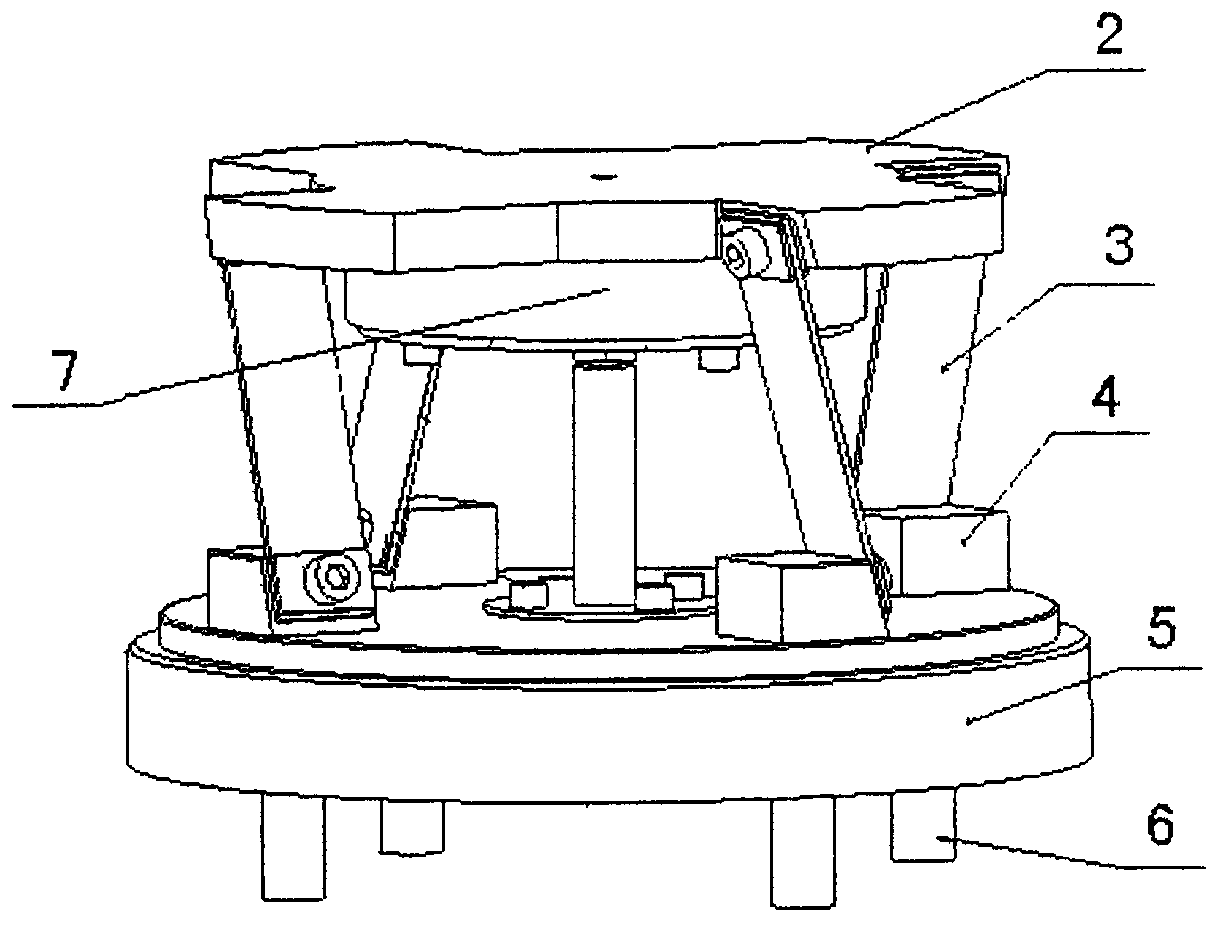

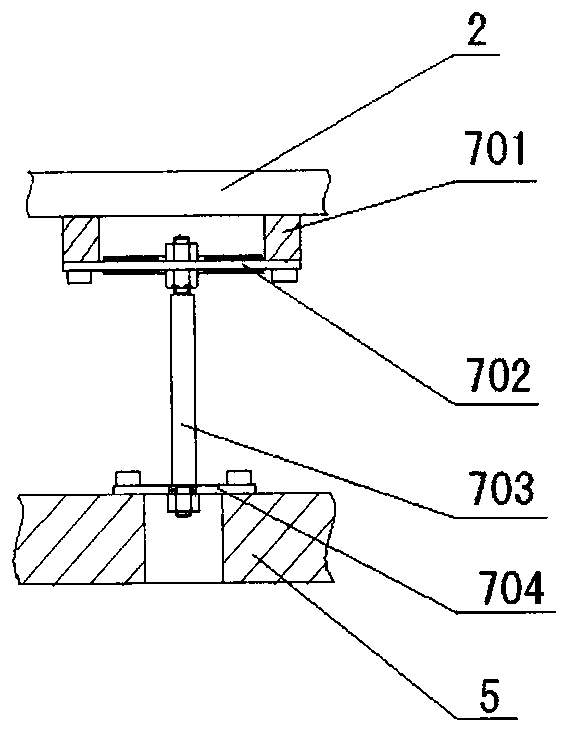

[0018] Embodiment 1: the application of double curved elastic supporting sheet in the rotary piezoelectric vibrating feeder, such as Figure 5 As shown, 3 (or more than 3) double-curved elastic support pieces 8 are evenly placed on the circumference of the base 5, and its lower mounting surface 803 is in contact with the base 5 and tightened by screws 804, and the upper mounting surface 802 is in contact with the top plate 2 and After tightening, the top plate 2 and the base 5 are connected by 3 (or more than 3) double-curved elastic support pieces 8 to form a vibration system, which has the ability to rotate and push materials. Wherein the top plate 2 and the base 5 can be discs with flat surfaces, and there is no need to process the installation slope 201 and the slope trapezoidal block 4, etc., and the structure is very simple.

Embodiment 2

[0019] Embodiment 2: the application of the double curved elastic supporting sheet in the linear piezoelectric vibrating feeder, such as Figure 6 As shown, 2 (or more than 2) double-curved elastic support pieces 8 are evenly placed on the rectangular base 10, and its lower mounting surface 803 is in contact with the rectangular base 10 and tightened by screws 804. The upper mounting surface 802 is connected to the rectangular top plate 9 Contact and tighten, then the rectangular top plate 9 and the rectangular base 10 are connected by 2 (or more than 2) double-curved elastic support pieces 8 to form a vibration system, thus when pulled by the vertical vibration generated by the vibration source 7, The elastic supporting pieces 8 evenly distributed on the rectangular base 10 are elastically deformed to form left and right swings and vertical up and down vibrations, and a composite vibration of up and down and left and right is formed on the surface of the rectangular top plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com