Activated carbon filter paper and preparation method thereof

A technology of activated carbon and filter paper, which is applied in the field of activated carbon filter paper and its preparation, can solve the problems of waste of activated carbon, high price of activated carbon filter paper, increase of product production cost, etc., and achieve the effect of easy control, excellent filtering effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

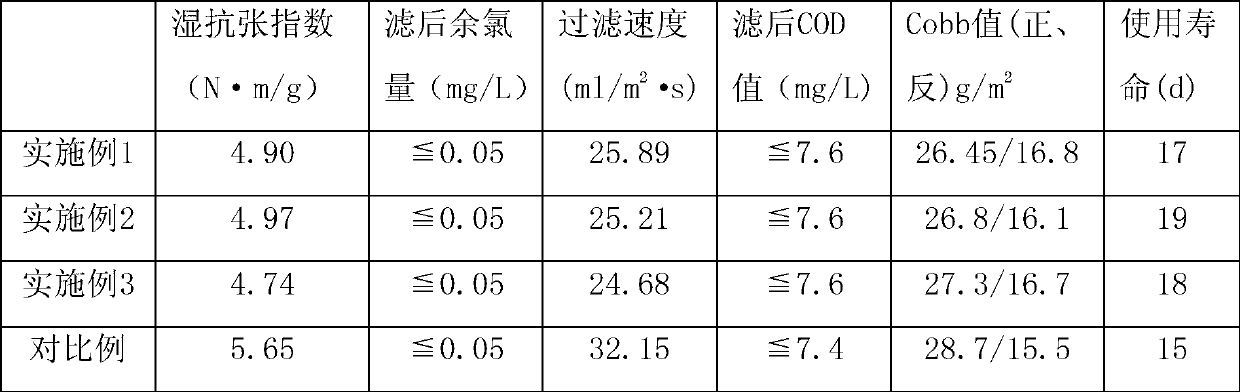

Examples

Embodiment 1

[0022] (1) Put 20kg of wood pulp and 16.5kg of polyester fiber into the pulper at the same rate for pulping. The pulped pulp enters the pulp tank through the pulp pump, and then pumps to the double-disc refiner for further processing. On-line refining to achieve a beating degree of 45°SR;

[0023] (2) Use the suction method to add 60kg of activated carbon powder with a particle size of 200 mesh into the closed mixing tank and mix it with water, and stir evenly.

[0024] (3) Add the wet activated carbon into the pulp slurry, stir evenly to obtain a pulp, and the pulp is formed by inclined wire to obtain base paper.

[0025] (4) Take 2kg of wet strength agent PAE, 1kg of dry strength agent AKD, and 0.5kg of retention aid cationic polyacrylamide, mix and stir evenly, put them into the impregnation machine, and pass the base paper obtained above through the unwinding frame and the guide. The paper roll enters the impregnation machine, adjust the guide roller and paper guide rolle...

Embodiment 2

[0030] (1) Put 15kg of wood pulp and 12kg of polyester fiber into the pulper at the same rate for pulping. The pulped pulp enters the pulp tank through the pulp pump, and then pumped to the double-disk refiner for online processing. Refining reaches a beating degree of 45°SR;

[0031] (2) Use the suction method to add 70kg of activated carbon powder with a particle size of 250 mesh into the closed mixing tank and mix it with water, and stir evenly.

[0032] (3) Add the wet activated carbon into the pulp slurry, stir evenly to obtain a pulp, and the pulp is formed by inclined wire to obtain base paper.

[0033] (4) Take 1.5kg of wet strength agent PAE, 1kg of dry strength agent AKD, and 0.5kg of retention aid cationic polyacrylamide, mix them evenly, put them into the impregnation machine, and pass the base paper obtained above through the unwinding rack and guide rollers into the dipping machine, adjust the guide rollers and guide rollers of the unwinding frame, so that the b...

Embodiment 3

[0038] (1) Put 18kg of wood pulp and 15kg of polyester fiber into the pulper at the same rate for pulping. The pulped pulp enters the pulp pool through the pulp pump, and then pumped to the double-disc refiner for online processing. Refining reaches a beating degree of 45°SR;

[0039] (2) Add 64kg of activated carbon powder with a particle size of 300 mesh into the closed mixing tank by suction method and mix with water, stir evenly,

[0040] (3) Add wet activated carbon into the pulp slurry, stir evenly to obtain a pulp, and form the pulp through inclined wire to obtain base paper;

[0041] (4) Take 1.6kg of wet strength agent PAE, 0.8kg of dry strength agent AKD, and 0.6kg of retention aid cationic polyacrylamide, mix them evenly, put them into the impregnating machine, and pass the above-mentioned The paper frame and paper guide roller enter the impregnation machine, adjust the paper unwinding frame guide roller and paper guide roller, so that the base paper is in a tensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com