Magnified backlight device made of a plurality of light guiding panel cells which are successively connected side by side with overlap

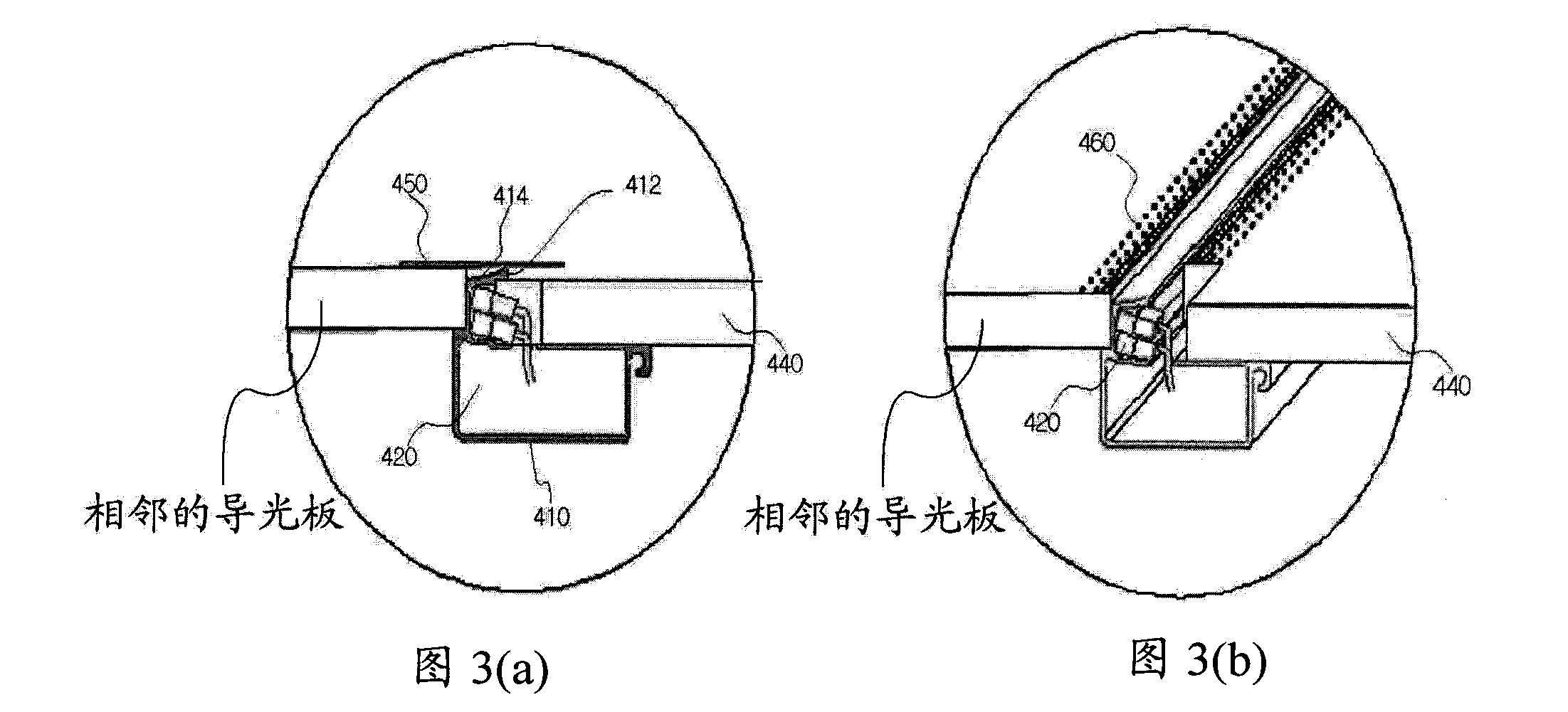

A technology for a backlight device and a light guide plate, which is applied to display devices, optical components, lighting devices, etc., can solve the problems of exposure in dense shadow areas, poor brightness, and easy deformation of the dispersing sheet 450, and achieve the effect of simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

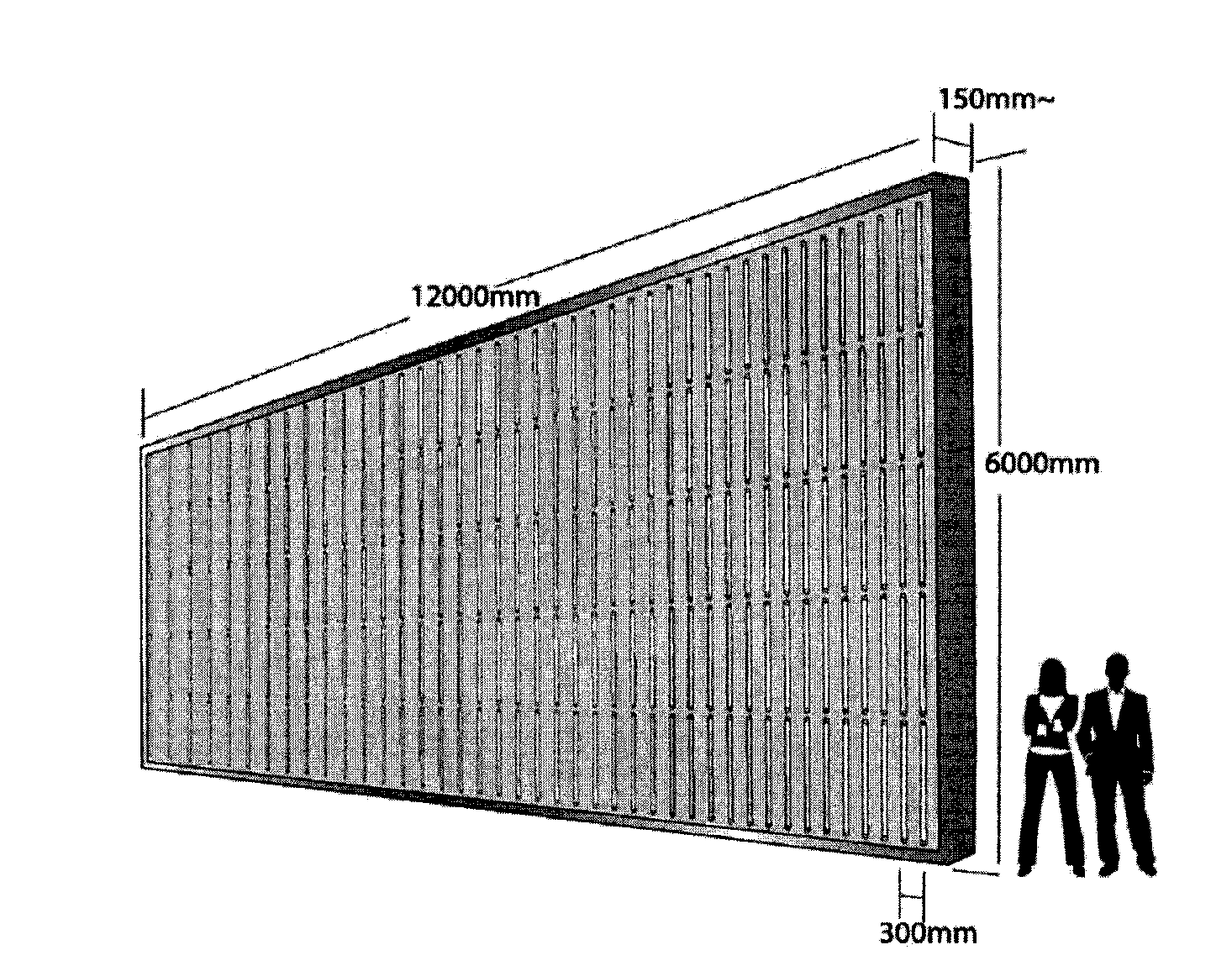

[0047] Figure 5 A backlight device 10 for an advertisement board having a large light guide plate assembly of 12000 mm x 6000 mm according to an embodiment of the present invention is schematically shown. The backlight device 10 is formed of a large light guide plate assembly 20 received and supported by a frame main body 30 . The large light guide plate assembly 20 can be formed by arranging and connecting 30 light guide plate units 22 , eg, 400mm×600mm, side by side to form a large surface emitting display.

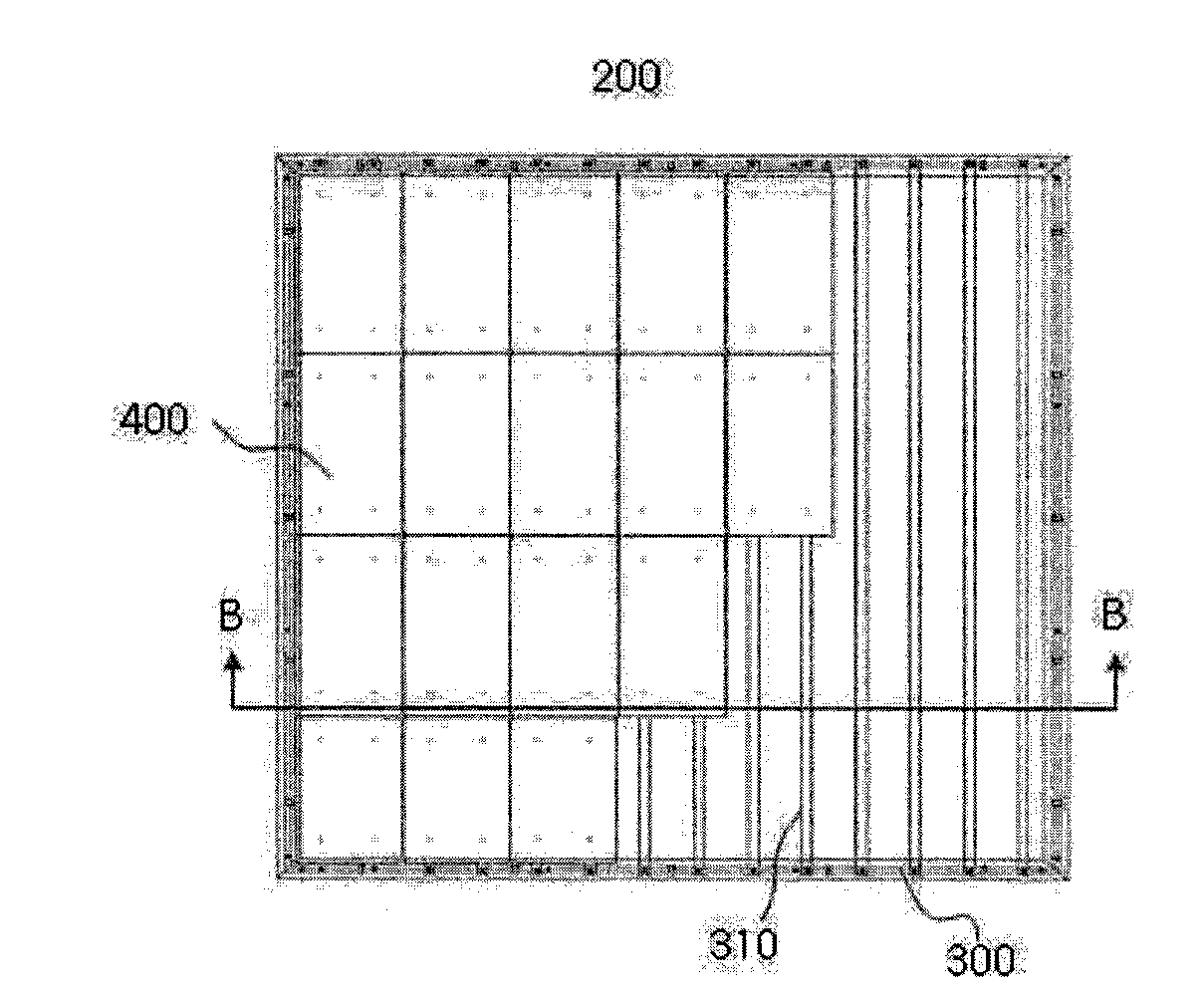

[0048] Image 6 The structure of the light guide plate unit 22 forming the light guide plate assembly 20 is shown. The light guide plate 24 is made of an acrylic resin plate. Specifically, since polymethyl methacrylate (PMMA) in acrylic resin has good transparency, light transmission properties, etc., PMMA has been widely used in backligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com