Solution type constant-temperature dehumidifier and control method thereof

A control method and solution-based technology, which is applied in heating and ventilation control systems, refrigerators, compressors, etc., can solve the problems of heating and regeneration of dehumidification liquid in refrigeration systems, reduce power consumption of equipment, enrich sources of cold sources, and prevent The effect of over evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment the present invention is described in further detail:

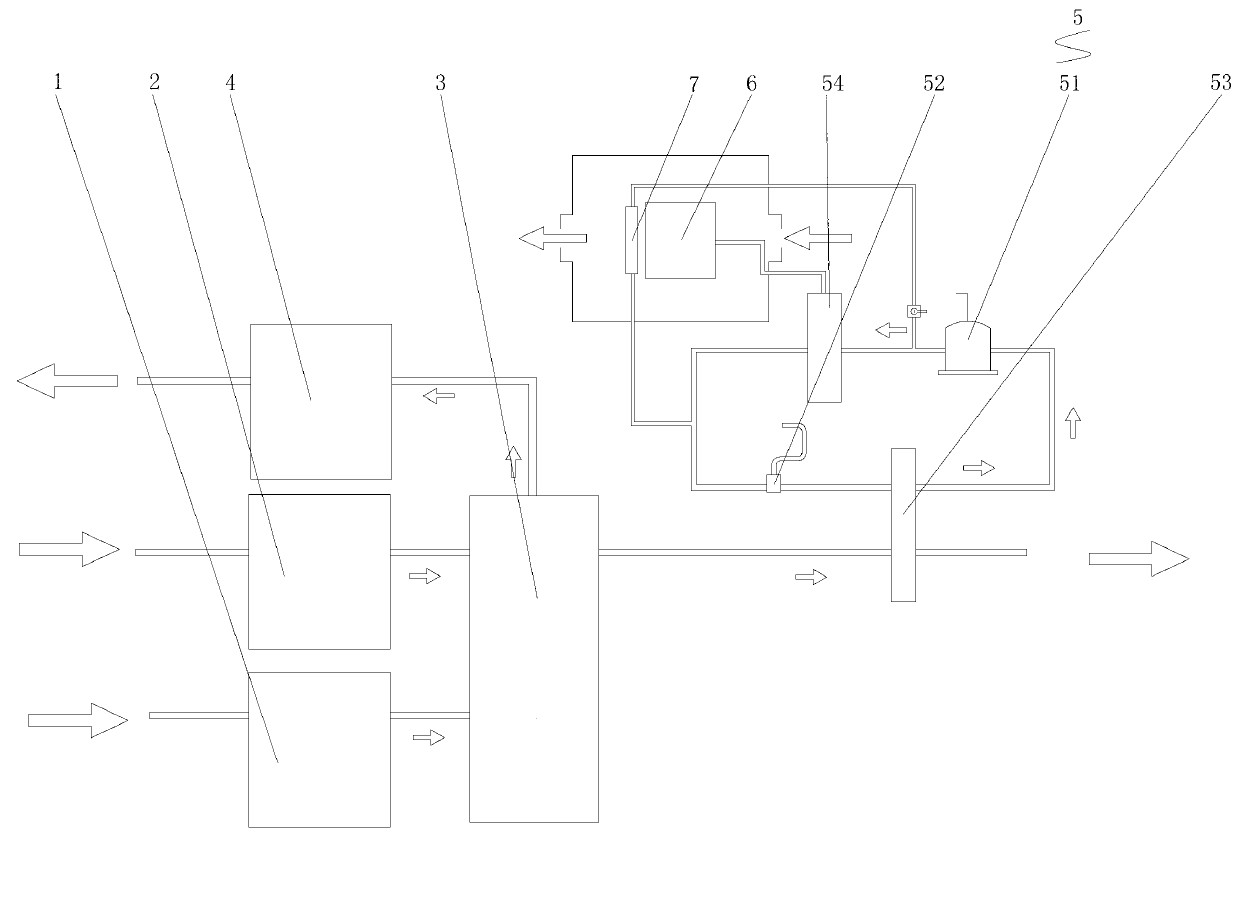

[0028] Such as figure 1 As shown, the solution type constant temperature dehumidifier of the present invention includes two groups of dehumidifiers 1, 2, dew point indirect evaporative cooler 3, direct evaporator 4 and refrigeration system 5, and the output ends of the two groups of dehumidifiers 1, 2 are all connected to the dew point The input end of the indirect evaporative cooler 3 is connected, and the output end of the dew point indirect evaporative cooler 3 is connected with the input end of the direct evaporator 4, and the direct evaporator 4 is also respectively connected with two groups of dehumidifiers 1 and 2; the dew point indirect evaporative cooler 3. The other output end is connected with the refrigeration system 5.

[0029] The present invention uses two sets of dehumidifiers 1 and 2 to dehumidify the inhaled outdoor low-temperature air and return air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com