Real-time temperature, optical band gap, film thickness, and surface roughness measurement for thin films applied to transparent substrates

A technology for surface roughness, transparent substrates, applied in the direction of using optical devices, measuring devices, scattering characteristics measurement, etc., can solve problems such as inability to obtain stable or reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

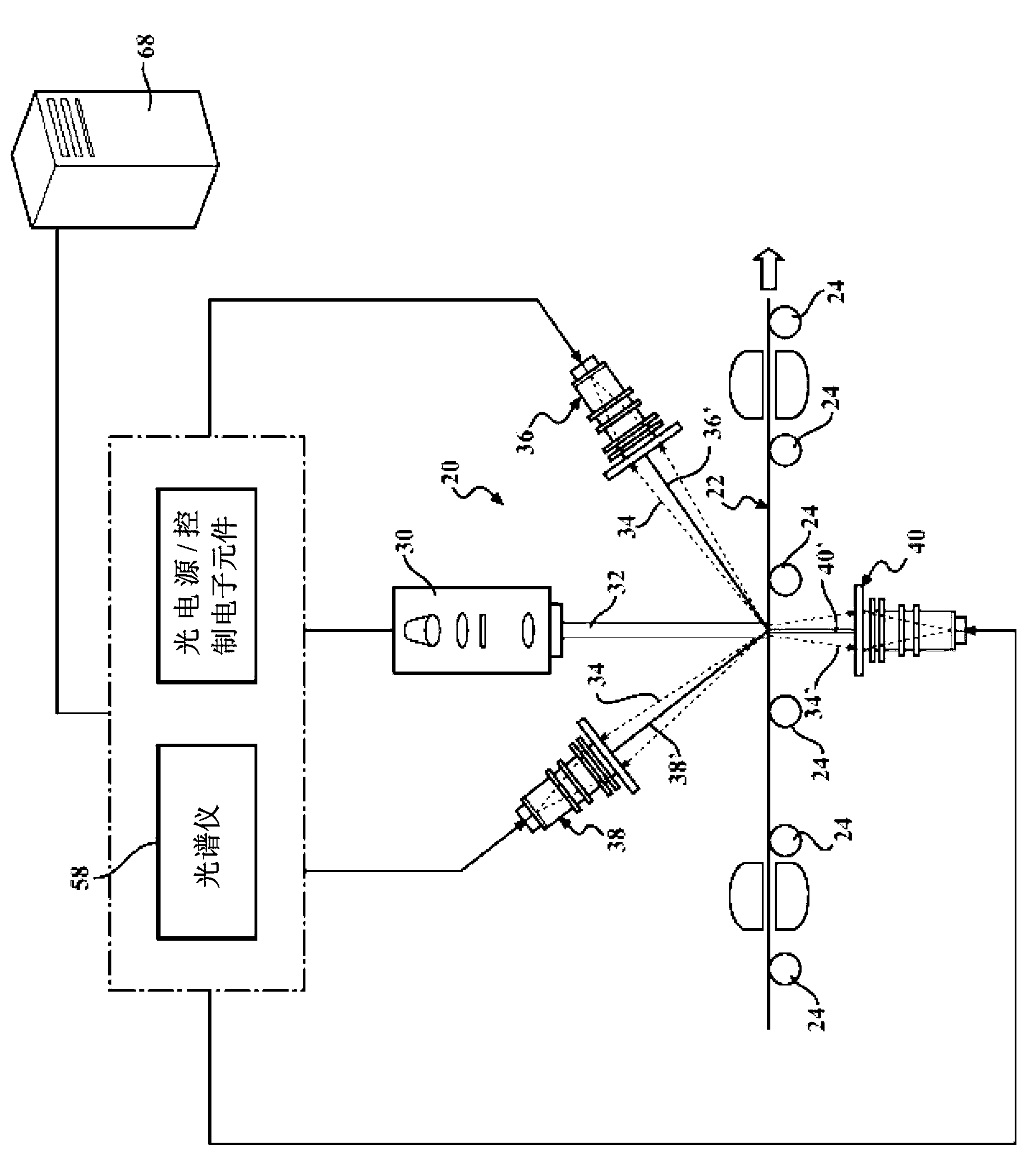

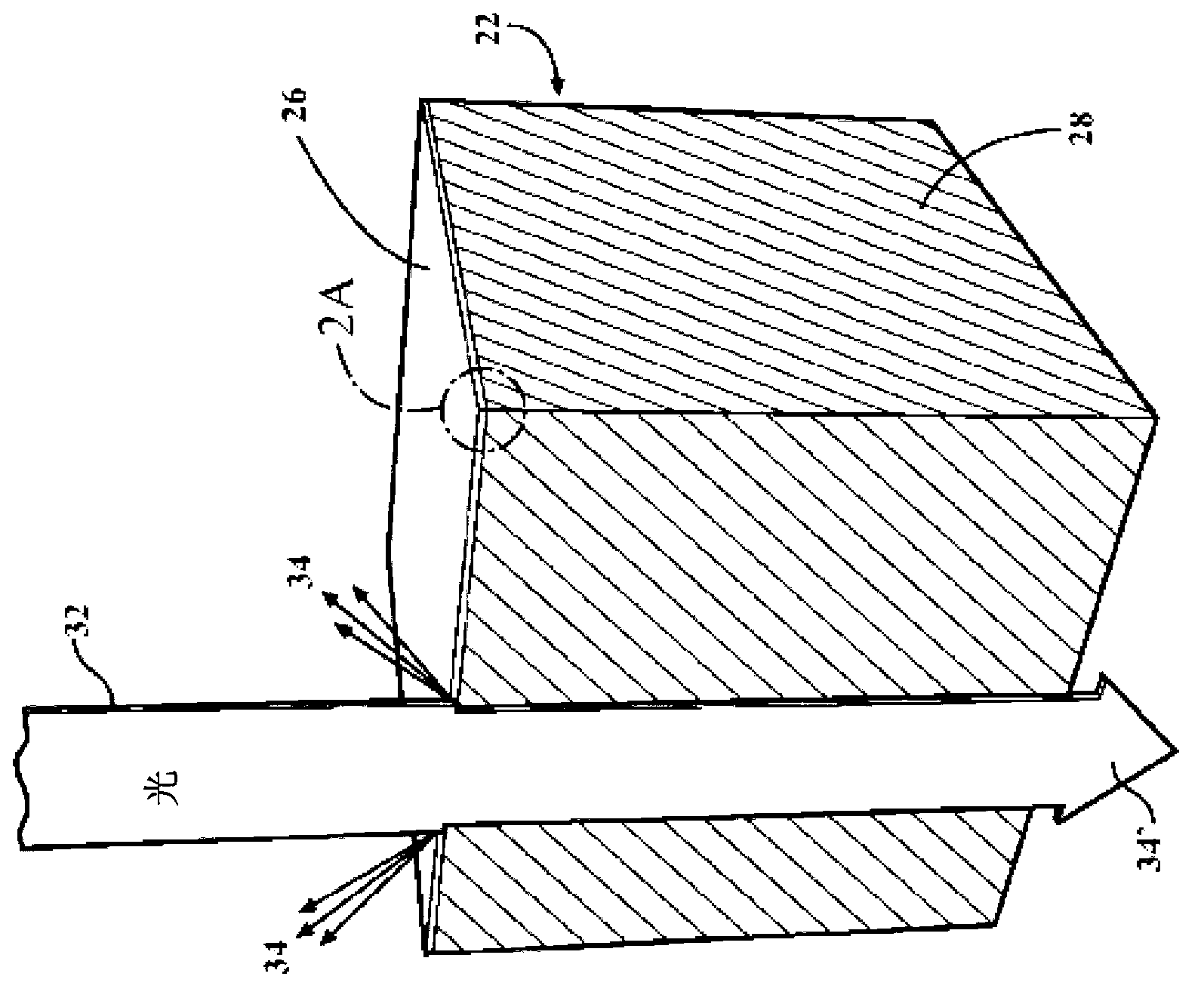

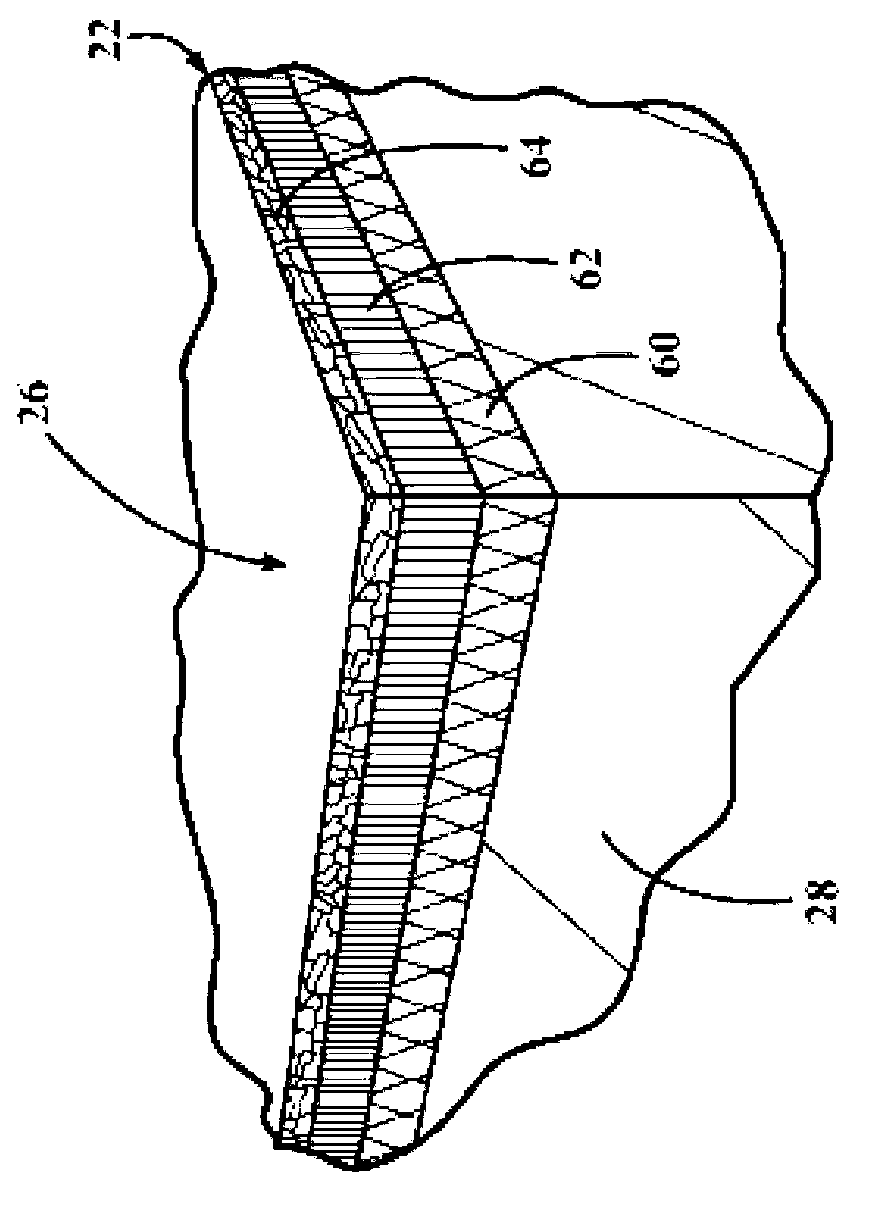

[0036] Referring to the drawings, wherein like reference numerals are used to indicate like or corresponding parts in the various views, an absorption edge measurement system according to the present invention is shown generally at 20 . The system 20 is particularly suited for in-line measurement of material 22 moving along a conveyor system 24 . Typical materials 22 include the production of photovoltaic solar panels on which a thin film absorber layer 26 is applied across a glass (or other suitable) substrate 28 . Substrate 28 and membrane 26 are shown schematically in Figures 2, 2A, 3A and 3B. It should be understood that film 26 may actually consist of multiple discrete layers, as shown in FIG. 2A. The thin film component 26 can be any typical material, including but not limited to CdTe, CIGS, CdS, textured polysilicon, GaAs, Si, SiC, InP, ZnSe, ZnTe, SrTi. 3 and GaN.

[0037] In the particular example of a photovoltaic panel product, in which the materials 22 comprise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com