Adjustable automatic scraping and grinding system

An adjustable and automatic technology, applied in the field of mechanical processing, can solve the problems of restricting machine tool manufacturing cycle, long construction period, and many processes, and achieve the effect of short processing time, high precision and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

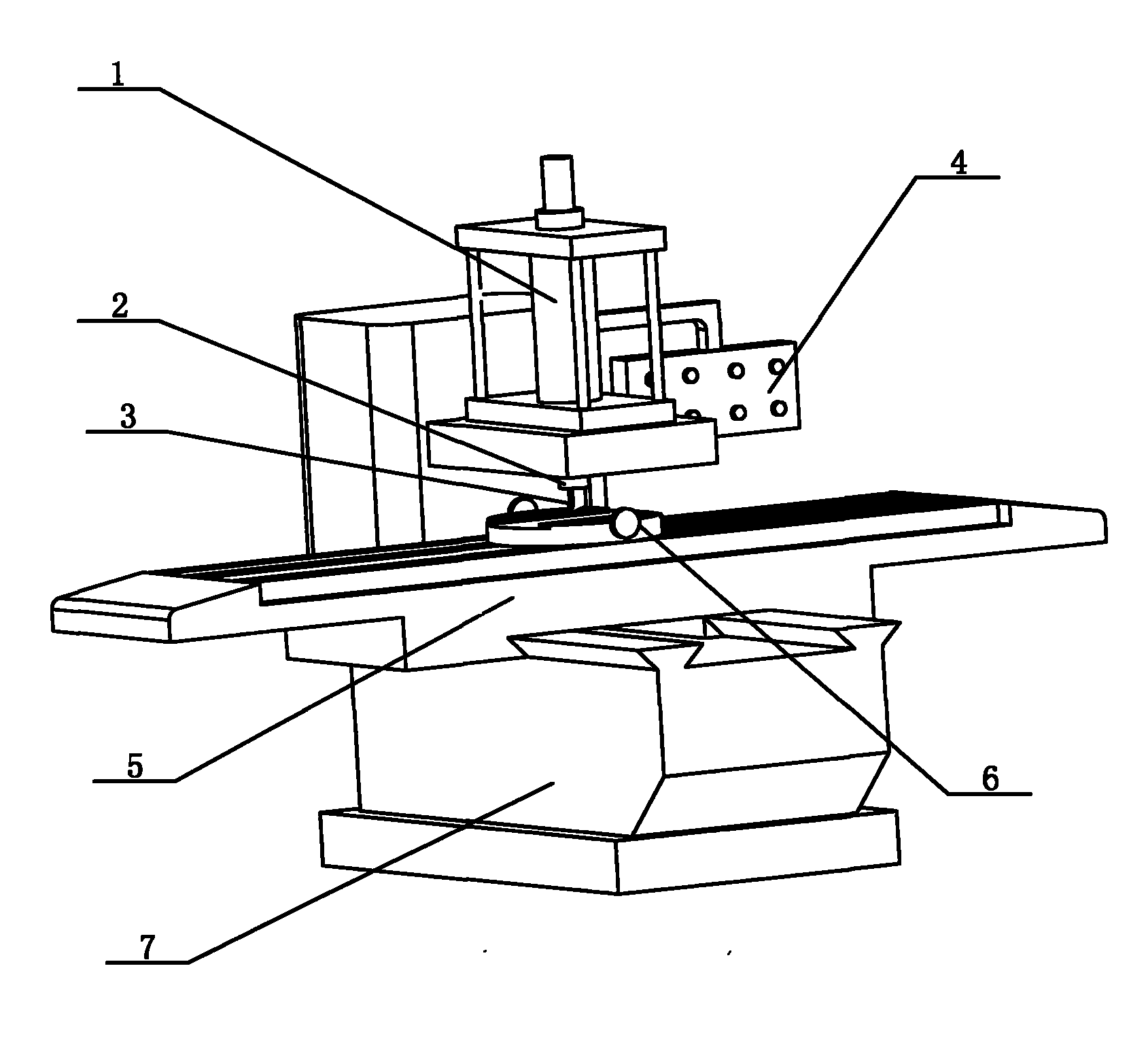

[0014] Specific implementation mode one: see figure 1 , the specific embodiment adopts the following technical solutions: it includes a pneumatic cylinder 1, a fixture 2, a scraping knife 3, an operation panel 4, a three-degree-of-freedom rectangular coordinate system work platform 5, a rotatable fixture 6 and a bed 7, and a scraping knife 3. The clamp 2 is connected to the pneumatic cylinder 1. The operation panel 4 is set on the right side of the pneumatic cylinder 1. The three-degree-of-freedom rectangular coordinate system working platform 5 is installed on the bed 7, and the rotatable fixture 6 is fixed on the three-degree-of-freedom rectangular coordinate system platform. 5 on.

[0015] The pneumatic cylinder 1 controls the reciprocating movement of the scraping knife 3 through the control panel 4, the speed is 30 / min, the stroke is 60 mm, and the feed speed in the x direction is 3.25 mm / s. Select the width of the scraping head to be 5mm, and the area of the scraping ...

specific Embodiment approach 2

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the feed speed of the scraping knife is 40 / min, the stroke is 90 mm, and the feed speed in the x direction is 4.2 mm / s. The average grinding point (25mm×25mm) of the scraping square is 18, and other scraping grinding environments and scraping grinding objects are the same as those in Embodiment 1.

specific Embodiment approach 3

[0023] Specific embodiment three: the difference between this specific embodiment and specific embodiment one is that the feed speed of the scraping knife is 50 / min, the stroke is 70 mm, and the feed speed in the x direction is 4 mm / s. The square average grinding point (25mm×25mm) is 19, and the other scraping environment and scraping objects are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com