High-efficiency submerged arc welding welding backing

A welding backing and submerged arc welding technology, which is applied in the field of welding and arc welding materials for steel materials, can solve the problems that the production efficiency of submerged arc single-sided welding cannot meet the needs of welding production development, and avoid welding bump defects and welding toes Neat and beautiful, improve the effect of welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

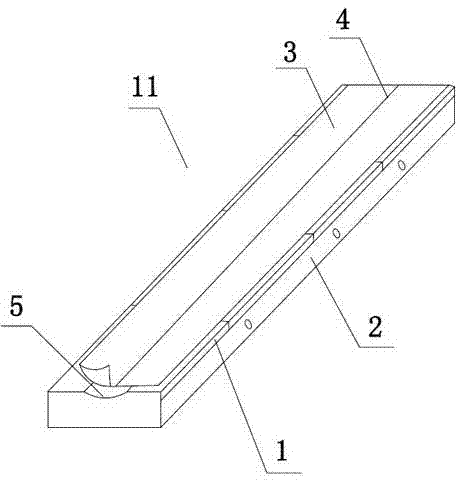

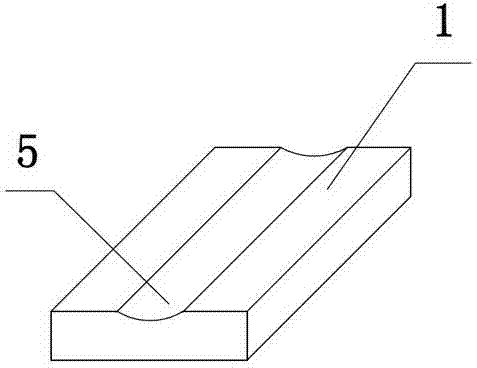

[0023] Example 1. The invention provides a high-efficiency submerged arc welding backing 11 for high-efficiency submerged arc automatic welding and semi-automatic single-sided welding. The high-efficiency submerged arc welding backing 11 consists of several ceramic welding backing blocks 1 connected end to end, the bottom of the welding pad is wrapped in a strip-shaped reinforced shell 2, and the upper surface of the welding pad is provided with a layer of glass fiber tape 3 matching the size of the welding pad.

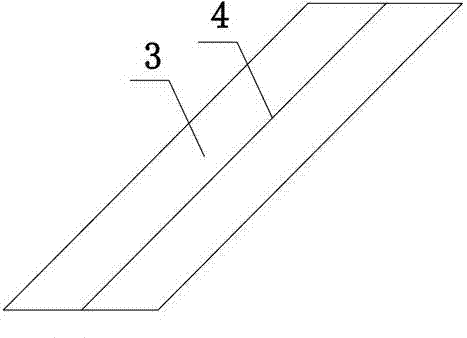

[0024] A centering line 4 is provided on the glass fiber strip. In this embodiment, a red fiber thread is embedded on the central axis of the glass fiber strip as the center line.

[0025] The glass fiber tape 3 is an alkali-free glass fiber tape 3 .

[0026] The thickness of the glass fiber tape 3 is 0.8-1.2mm.

[0027] The glass fiber strip 3 is rectangular, the length of the rectangle matches the length of the pad 11 , and the width is 3-4mm smaller than the wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com