SnCuNiGaGeIn serial silver-free and lead-free solder alloy

A lead-free solder alloy, weight percentage technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of large amount of phosphorus volatilization, large tin slag, affecting product quality, etc., to improve resistivity, Use effect is good, the effect of improving anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

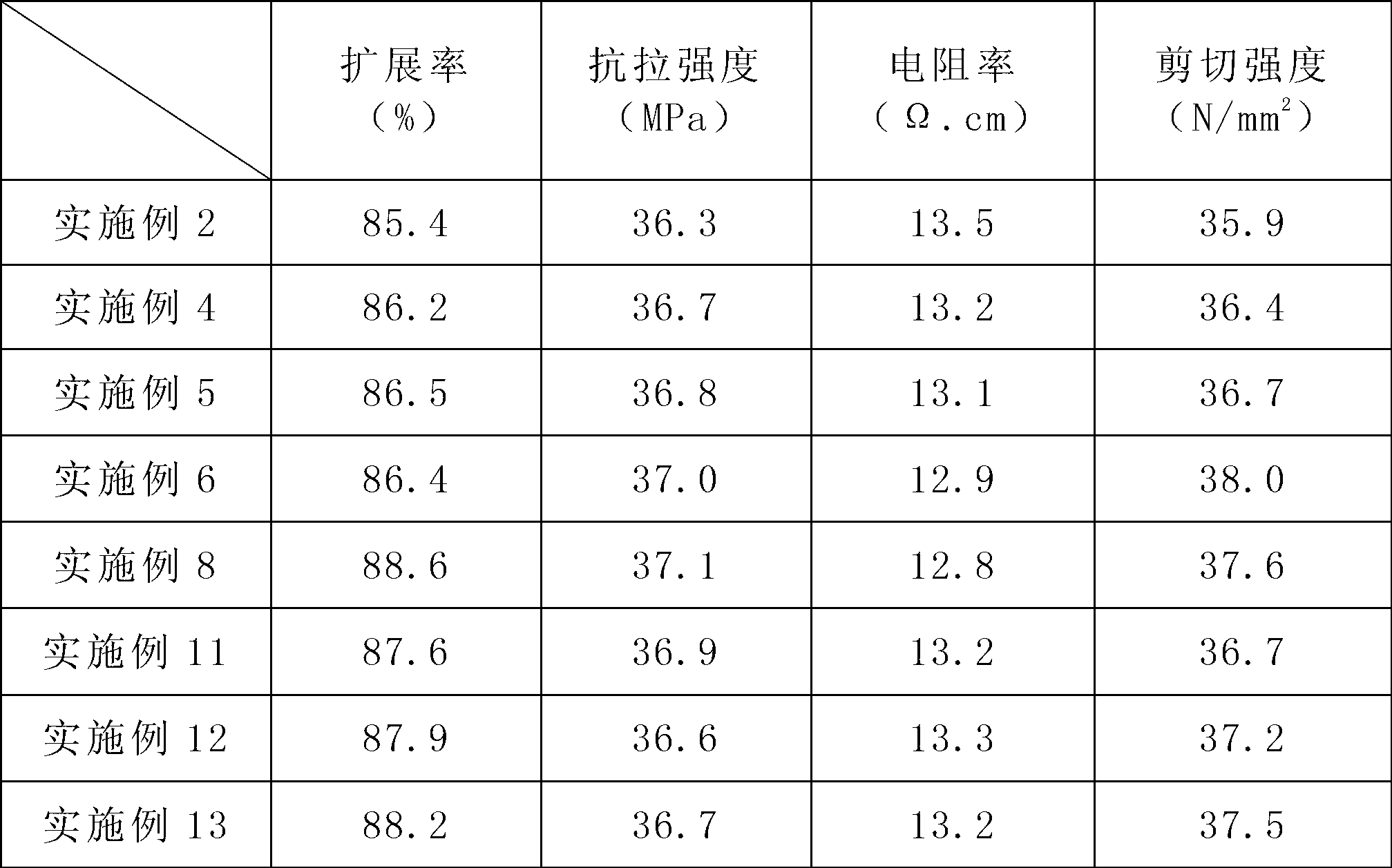

Examples

Embodiment 1

[0023] A kind of SnCuNiGaGeIn system silver-free lead-free solder alloy, this lead-free solder alloy is made up of the weight percent of following composition:

[0024] Cu: 0.5%; Ni: 0.01%; Ga+Ge: 0.005%, where the weight ratio of Ga+Ge is 1:1; In: 0.09%; the balance is Sn, which also contains inevitable impurities.

[0025] The preparation method of the silver-free lead-free solder alloy of the present embodiment is as follows:

[0026] A. Add Ni to the vacuum high-frequency electric furnace according to the above weight percentage, and then add a part of Sn. The weight ratio of Sn to Ni added is 9:1. Raise the temperature to 1600°C and keep it for 30 minutes, take it out of the furnace, cool and cast Sn-Ni alloy ingot;

[0027] B. Put the Sn-Ni alloy ingot alloy obtained in step A and the remaining Sn into an intermediate frequency electric furnace, heat up to 480° C., smelt, and keep warm for 30 minutes; then, cool down to 320° C., add Cu, Stir Ga and Ge for 30 minutes. A...

Embodiment 2

[0029] A kind of SnCuNiGaGeIn system silver-free lead-free solder alloy, this lead-free solder alloy is made up of the weight percent of following composition:

[0030] Cu: 0.6%; Ni: 0.01%; Ga: 0.0025%; Ge: 0.0027%; In: 0.09%; the balance is Sn, including unavoidable impurities.

[0031] The preparation method of the silver-free lead-free solder alloy of this embodiment is consistent with the method of embodiment 1, the only difference is that the weight percentage of each component of the silver-free lead-free solder alloy of the SnCuNiGaGeIn system is added according to the ratio of this embodiment, and will not be repeated here. .

Embodiment 3

[0033] A kind of SnCuNiGaGeIn system silver-free lead-free solder alloy, this lead-free solder alloy contains the weight percent of following composition:

[0034] Cu: 0.6%; Ni: 0.02%; Ga: 0.003%; Ge: 0.0025%; In: 0.08%; the balance is Sn, including unavoidable impurities.

[0035] The preparation method of the silver-free lead-free solder alloy of this embodiment is consistent with the method of embodiment 1, the only difference is that the weight percentage of each component of the silver-free lead-free solder alloy of the SnCuNiGaGeIn system is added according to the ratio of this embodiment, and will not be repeated here. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com