Method and device for feeding airspace packet material of mixing system in rubber industry

The technology of a feeding device and a feeding method is applied in the field of raw material feeding of space bag packaging, which can solve the problems of affecting the quality of kneaded film products, difficulty in maintenance, and high operating costs, so as to save daily operating consumption costs and eliminate the need for Equipment maintenance costs and the effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

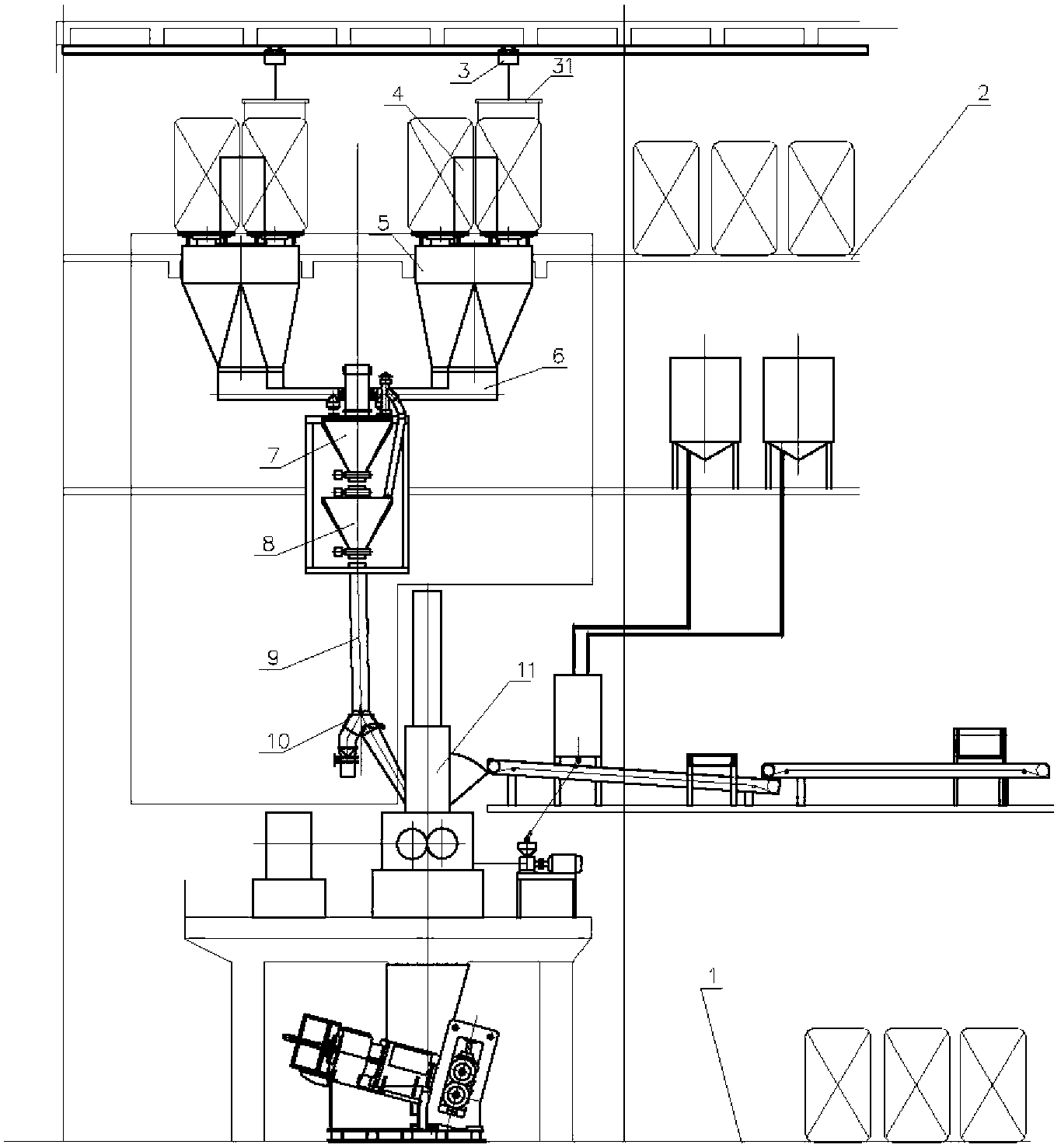

[0044] This embodiment provides a method for feeding raw materials into a space bag of a rubber industrial mixing system, which includes the following steps:

[0045] S1, space package raw materials are stored in the first temporary storage platform 1;

[0046] S2, according to the instruction of the first feeding console, the space bag raw material is transferred from the first temporary storage platform 1 to the second temporary storage platform 2 by means of mechanical transmission; the second temporary storage platform 2 is set on the One side of the raw material storage hopper 5 of the banburying system;

[0047] S3, according to the instructions of the second feeding console, the lifting device 3 transports the raw materials of the space bag from the second temporary storage platform 2 to directly above the feeding port of the raw material hopper 5 of the internal mixing system; the lifting The device 3 can be provided with a space bag special spreader 31 .

[0048] S4...

Embodiment approach

[0054] As a specific implementation, the instruction sent by the feed console can be:

[0055] The first feeding platform control command: transfer (mov) + the first temporary storage platform + the first temporary storage platform coordinates + the second temporary storage platform + the second temporary storage platform coordinates; the first feeding platform control command is mainly used to transfer Space package raw materials are transferred from the first temporary storage platform to the second temporary storage platform;

[0056] The second feeding table control command: transmission (mov) + the second temporary storage platform + the coordinates of the second temporary storage platform + the second temporary storage platform + the coordinates directly above the feeding port of the raw material storage hopper; the second feeding table The control command is mainly used to transfer the raw materials of the space package from the position of the second temporary storage ...

Embodiment 2

[0075] In order to realize the raw material feeding method described in Embodiment 1, the present invention also provides a space bag raw material feeding device of a rubber industrial mixer system, comprising a raw material storage hopper 5, a feed barrel 9 and a post-feeding hopper 10. The feeding device also includes a first conveying device, a first temporary storage platform 1, a second temporary storage platform 2 arranged on one side of the raw material storage hopper 5 of the rubber mixer system, a lifting device 3 and a feeding console; The feeding console is used to send instructions to the feeding device to control the entire feeding process, and at the same time control the specifications and batches of the raw materials.

[0076] The raw materials of the space bag in this embodiment are transported from the first temporary storage platform to the second temporary storage platform through the first conveying device, and then transported to the right above the raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com