All-weather wheel type mobile welding workshop

An all-weather, engineering vehicle technology, applied to motor vehicles, amphibious vehicles, vehicle parts, etc., can solve the problems of increased labor intensity of workers, inability to carry welding workers, and high transition costs, so as to improve steering flexibility and mobility Flexibility, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

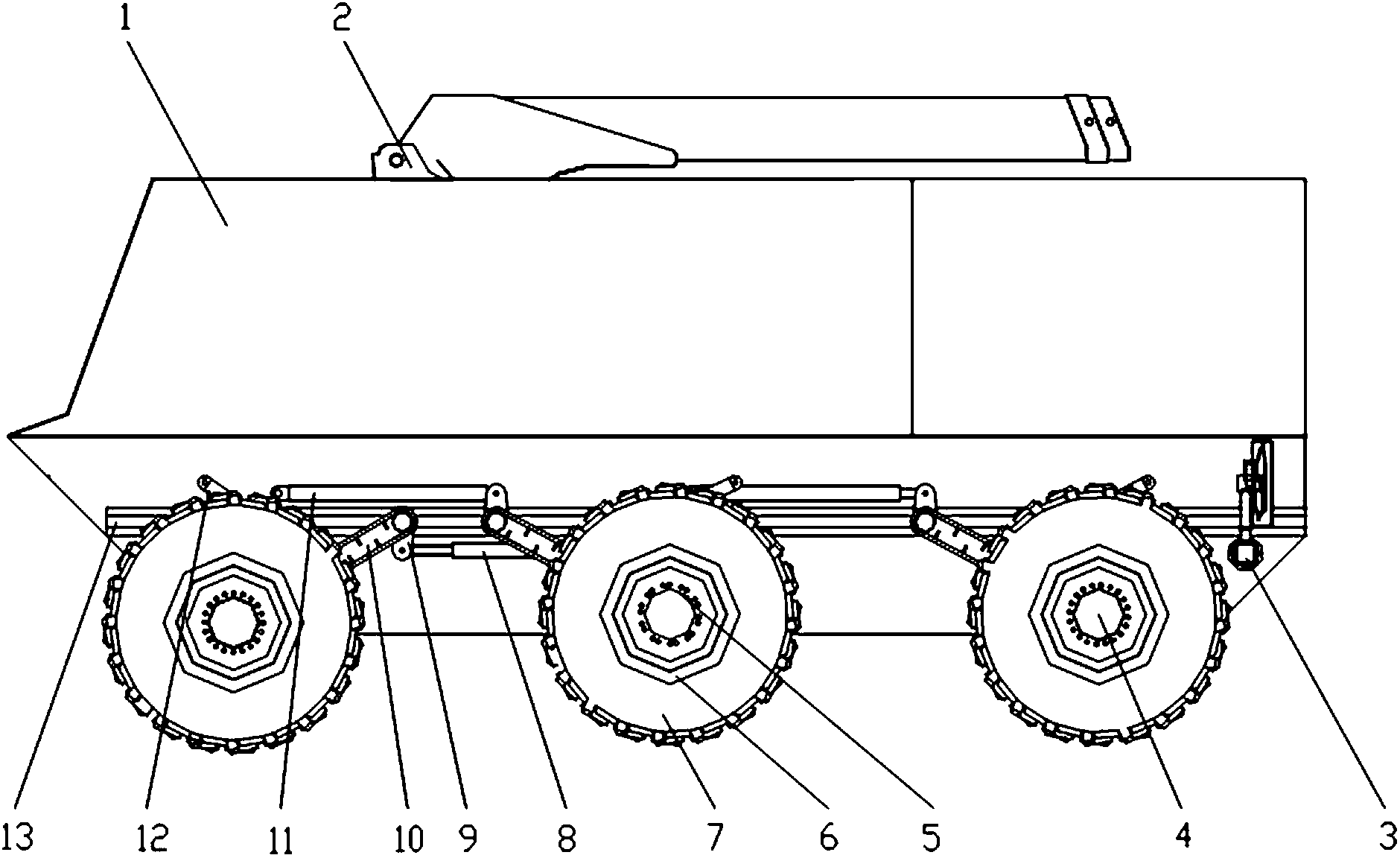

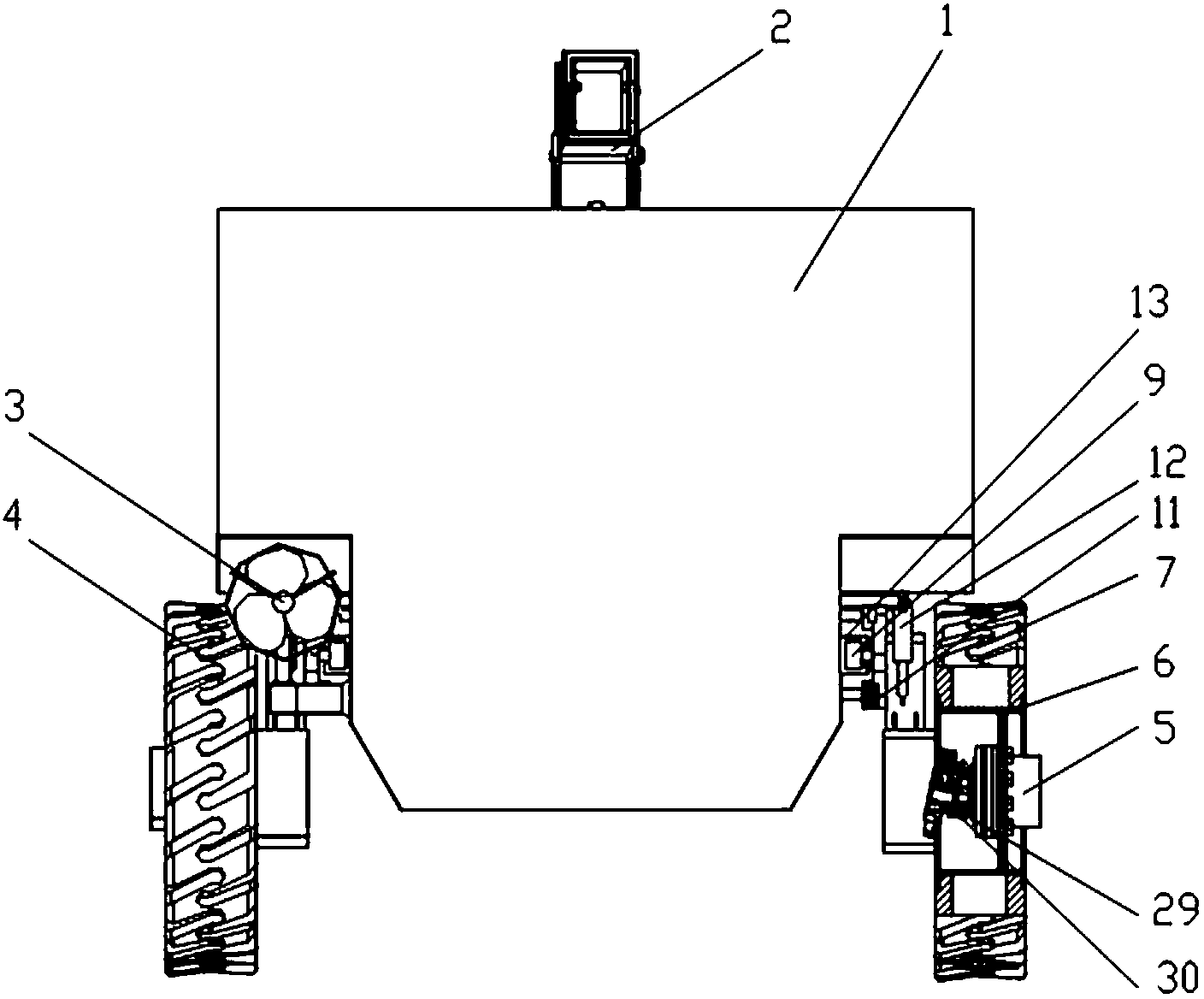

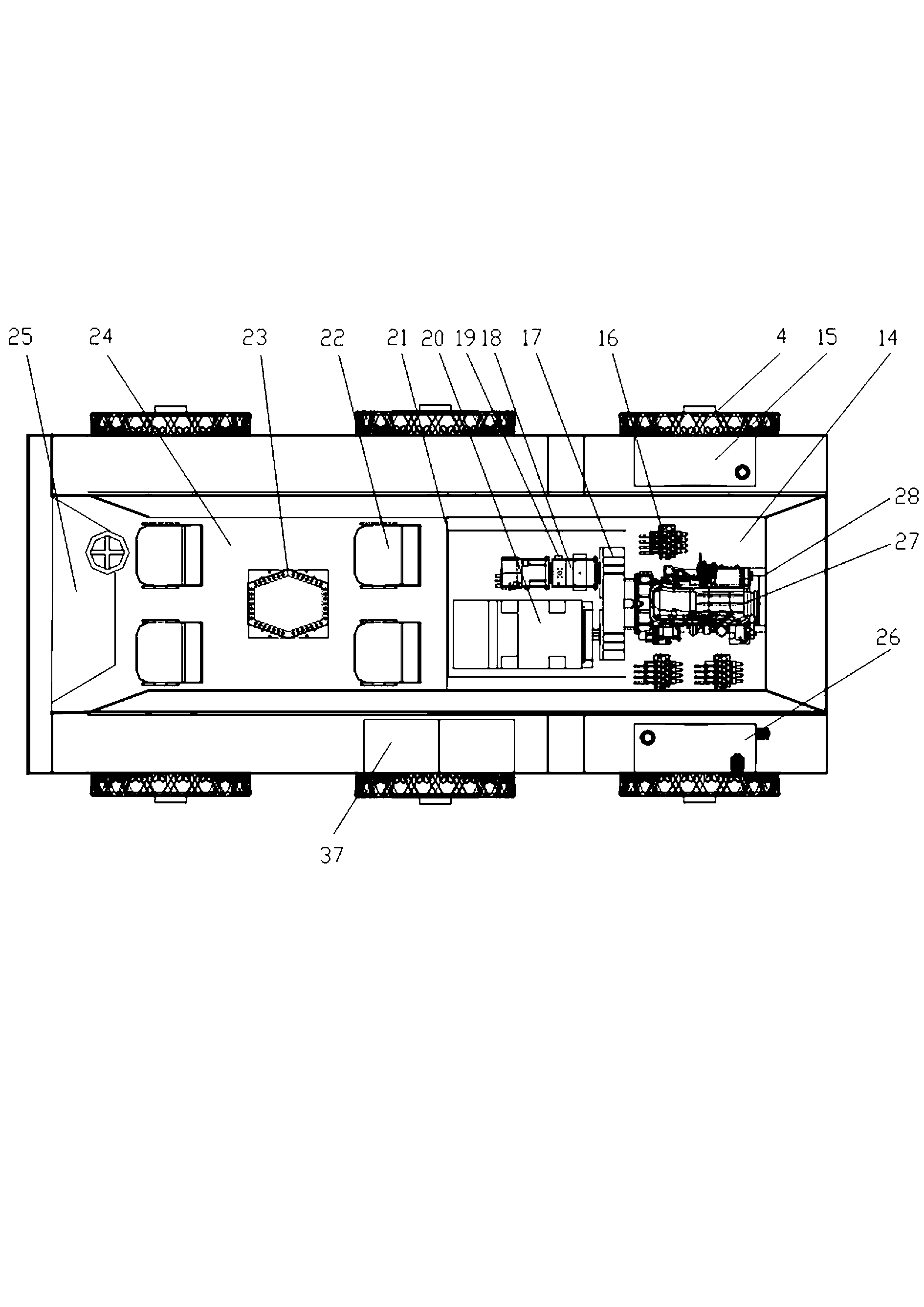

[0026] figure 1 , 2 . 3 is an embodiment disclosed by the present invention. This all-weather wheeled welding engineering vehicle includes a car body 1, a truck-mounted crane 2, a hydraulic wheel drive system 4, a power cabin 14, an electric welding machine 37, a passenger cabin 24 and a driving Platform 25, diesel oil tank 15 and hydraulic oil tank 26 are respectively installed in car body 1 afterbody both sides. The compensation rails 13 of the compensation type single trailing arm type independent suspension 11 are welded on both sides of the bottom of the car body 1, and three sliders 9 are installed on the compensation rail 13, and the upper ends of the suspension arms 10 of the three compensation type single trailing arm independent suspensions 11 are respectively It is hinged with three compensation sliders 9, and its lower end is flange-connected to one side of the three wheel reducers 5 of the hydraulic wheel drive system 4, and the three wheel reducers 5 on each sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com