Energy feedback suspension device having vibration energy recovery function

A technology of vibration energy recovery and energy recovery devices, which is applied in the direction of auxiliary drive devices, suspensions, elastic suspensions, etc., to achieve the effects of unaffected vibration reduction and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

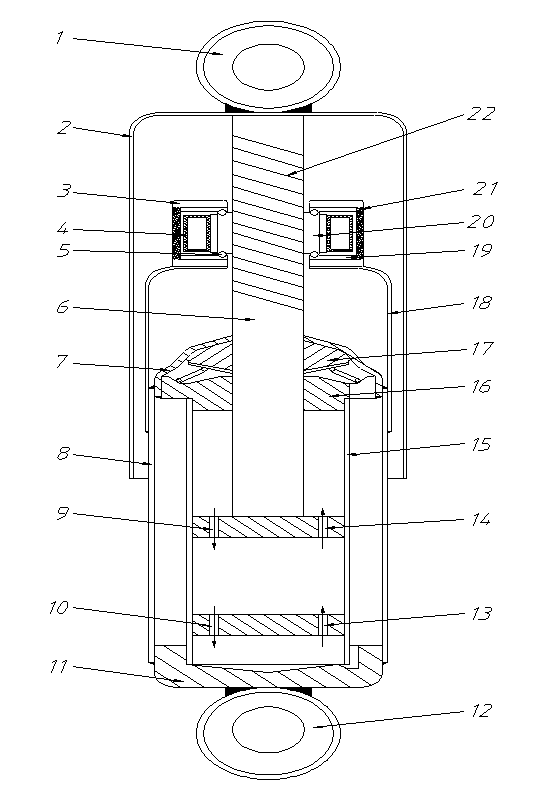

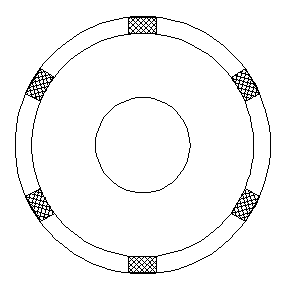

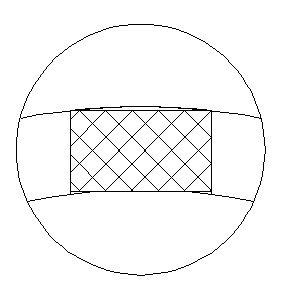

[0016] exist figure 1 Among them, the outer ring of the oil storage barrel 8 is welded with a bracket cylinder 18 for supporting the permanent magnet frame 3 . The permanent magnet frame 3 is an annular structure, as shown in figure (2), there are 6 permanent magnets 21 evenly distributed inside, and the permanent magnet frame is a non-sealed structure, so a magnetic field can be generated inside. (See image 3 )

[0017] The shock absorber piston rod 6 is partly designed as a screw structure 22 . Utilizing the principle of the ball screw, the up and down vibration of the piston rod is converted into the rotational motion of the screw nut 20 . The coil 4 surrounding the outer ring of the lead screw nut 20 rotates together with the lead screw nut 20, thereby cutting the magnetic field lines in the magnetic field generated inside the permanent magnet frame 3. As can be known from Faraday's law of electromagnetic induction, The generated current is alternating current, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com