Suspension device with members on side surfaces

A component and suspension technology, applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc., can solve the problems of not being able to play the role of vibration isolation and vibration reduction, the frequency of vibration mode is not the same, and the external area is not large, so as to achieve strengthening Vibration isolation and vibration reduction effect and work performance, easy production and assembly, and the effect of increasing the external area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation of a suspension device with side members of the present invention will be described in detail below in conjunction with the accompanying drawings.

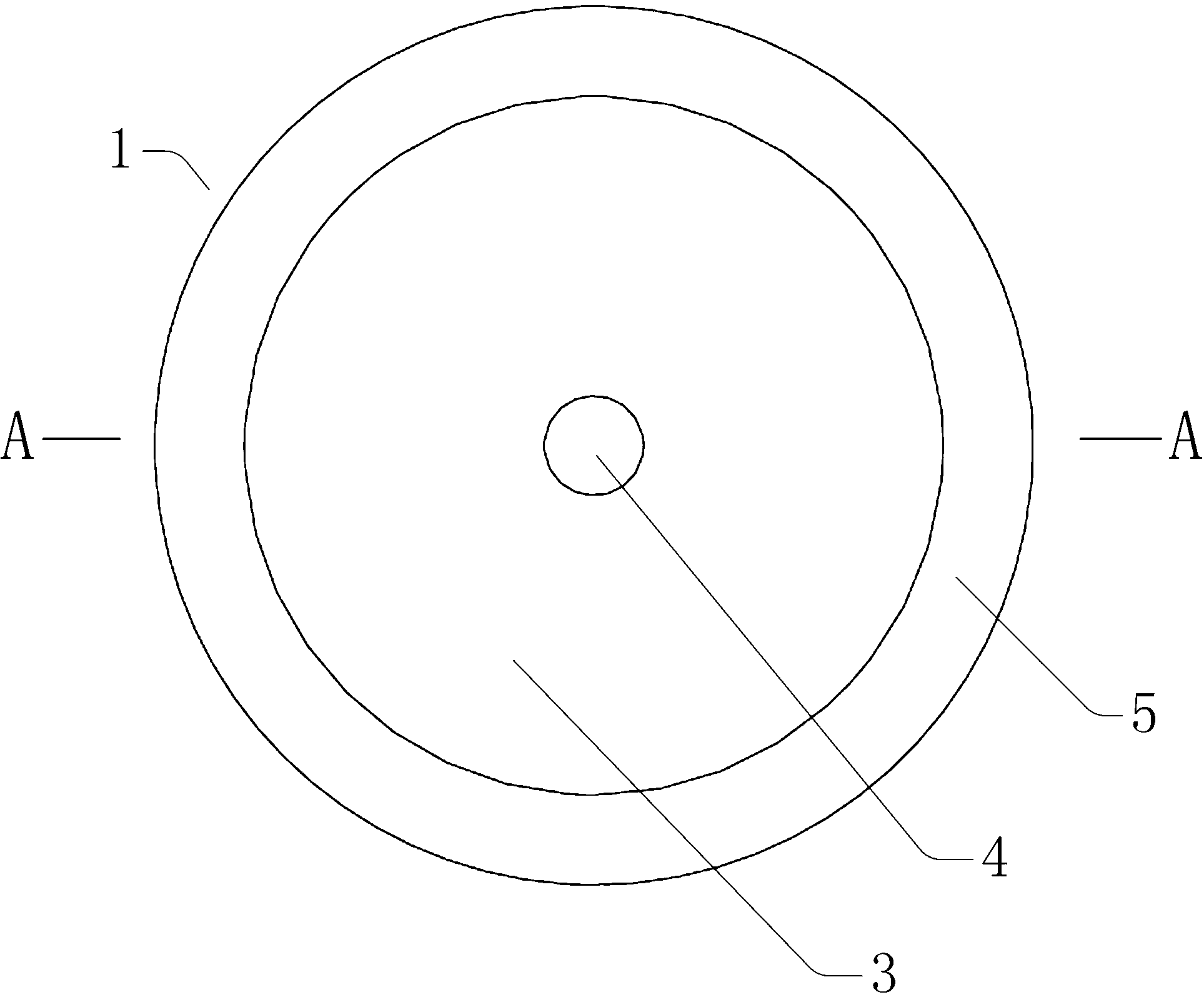

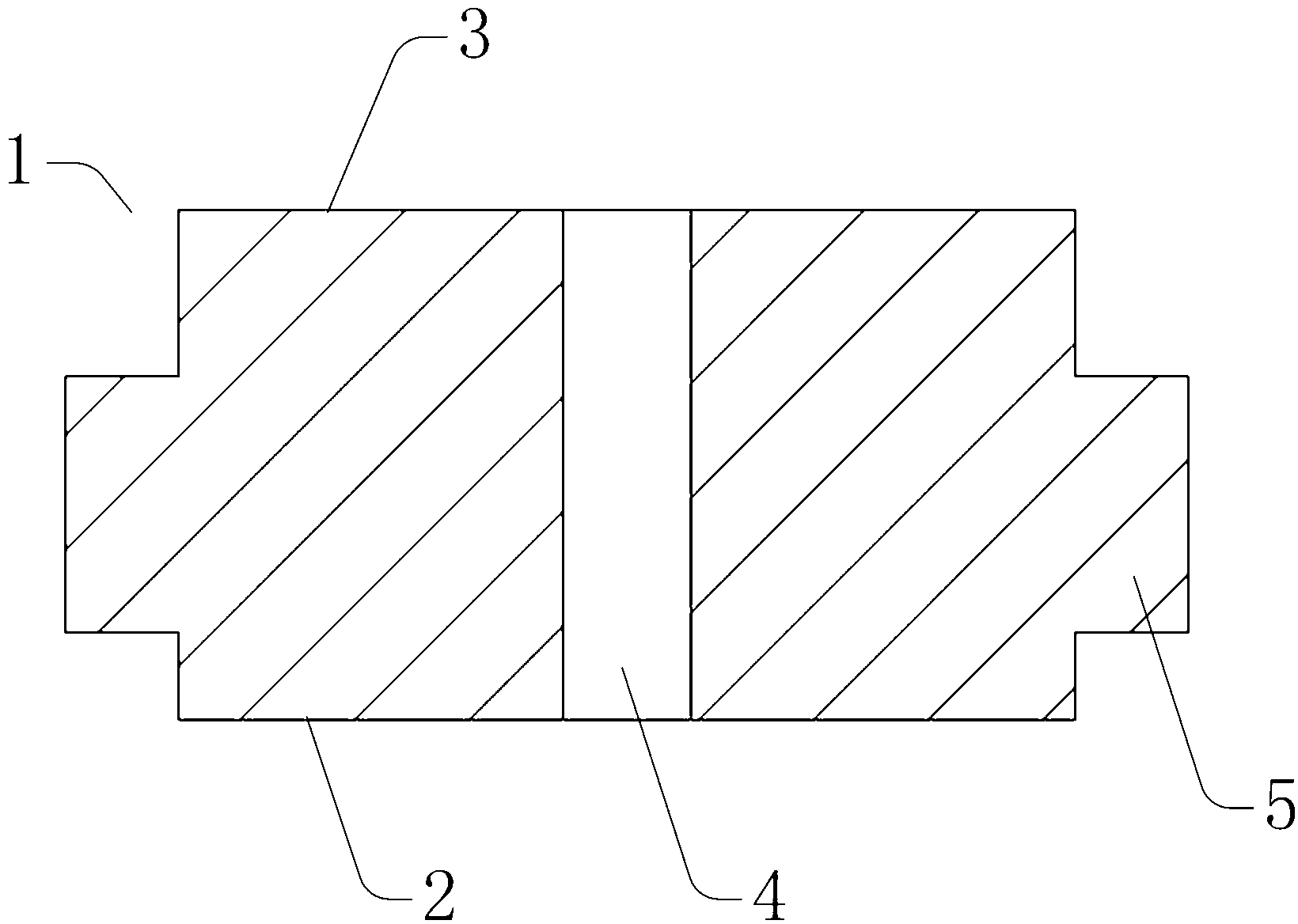

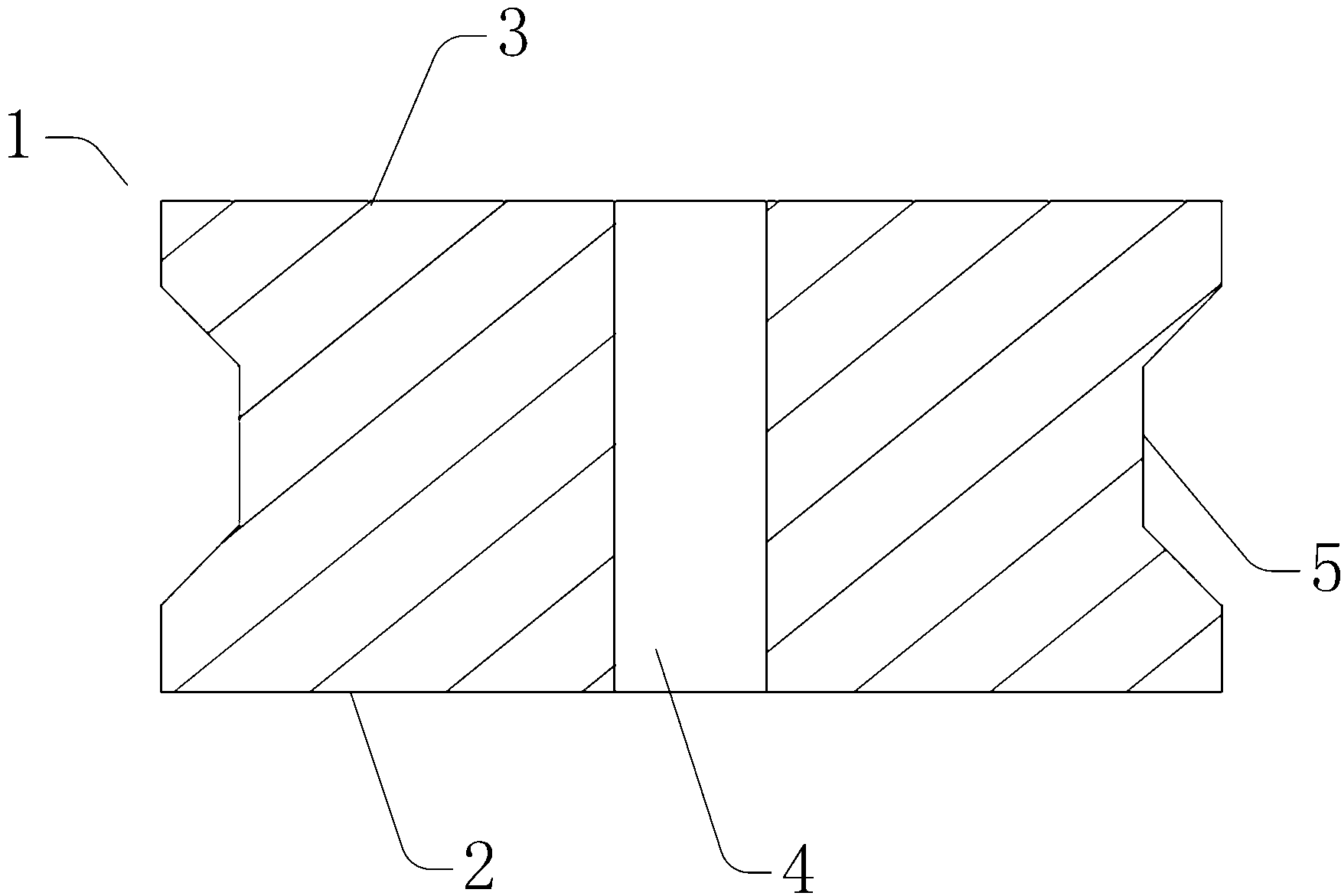

[0031] refer to Figure 1A and Figure 1B , a suspension device with components on its sides includes a main component 1 . The main part 1 includes a first face 2 and a second face 3 opposite to the first face 2. The center of the main part 1 is provided with a first through hole 4, and the first through hole 4 is along the vertical direction of the first face 2. and the direction of the second surface 3 runs through the main part 1 .

[0032] A member 5 for changing the state of the side surface of the main part 1 is provided on the side of the main part 1 . In the prior art, the side of the main part 1 has a smooth structure, which results in a relatively simple structure of the main part 1. Most of the main part 1 is cylindrical or truncated circular, and the mode structure is single, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com