Marine self-priming pump water spray propelling outboard engine

A technology of water jet propulsion and self-priming pump, which is applied in the direction of ship propulsion, propulsion parts, ship parts, etc. It can solve the problems of high energy consumption, complex structure of outboard motor, inconvenient installation and maintenance, etc., and achieve stable sailing performance and good appreciation value, the effect of reducing wave resistance and eddy current resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

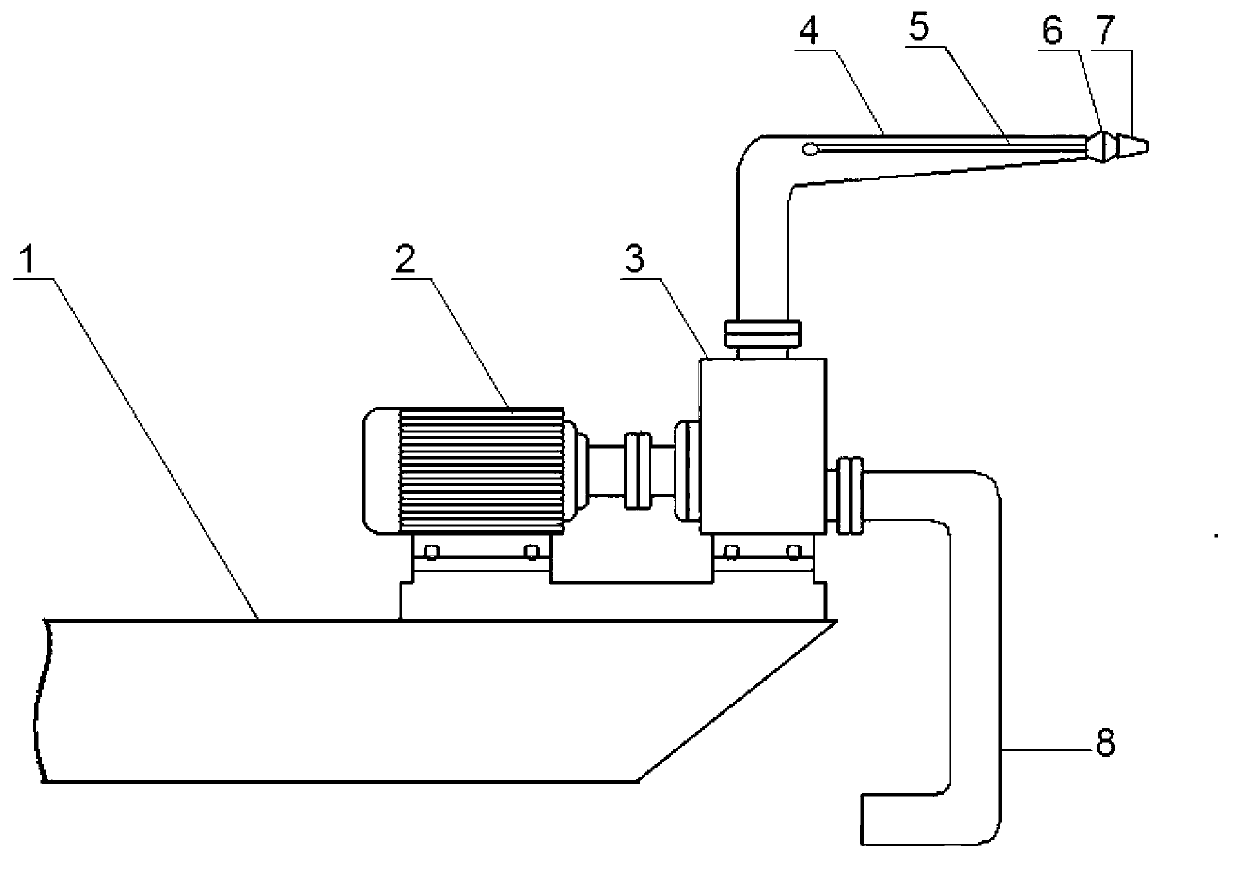

[0017] Such as figure 1 As shown, a marine self-priming pump water jet propulsion outboard motor is composed of an engine 2, a self-priming pump main body 3, a water outlet pipe 4, a direction joystick 5, a universal joint 6, a nozzle 7 and a water inlet pipe 8.

[0018] Engine 2 is connected with self-priming pump main body 3, and one end of water inlet pipe 8 is installed on the self-priming pump main body, and the other end of water inlet pipe 8 is water inlet, and water inlet is provided with strainer, and the direction of water inlet and the forward direction of hull 1 Consistent; one end of the water outlet pipe 4 is connected to the top of the main body 3 of the self-priming pump, the other end of the water outlet pipe 4 is a water outlet, and the direction of the water outlet is opposite to the forward direction of the hull. A nozzle 7 is installed at the water outlet of the water outlet pipe 4, and the nozzle 7 It is connected with the water outlet pipe 4 through a un...

Embodiment 2

[0020] The connection relationship and position relationship are the same as those in Embodiment 1, only the ratio of the inner diameter of the end of the water outlet pipe 4 connected to the main body 3 of the self-priming pump to the other end connected to the nozzle is changed to 4:1.

Embodiment 3

[0022] The connection relationship and position relationship are the same as those in Embodiment 1, only the ratio of the inner diameter of the end of the water outlet pipe 4 connected to the main body 3 of the self-priming pump to the other end connected to the nozzle is changed to 5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com