Shake-resistant anti-tilting leakage-proof ventilated liquid packing device and method

A liquid and leak-proof technology, which is applied in packaging, food packaging, transportation and packaging, etc. It can solve the problems of loose bottle caps, sideways or upside down, bumps, etc., to reduce the area, reduce the probability of contact, and ensure ventilation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

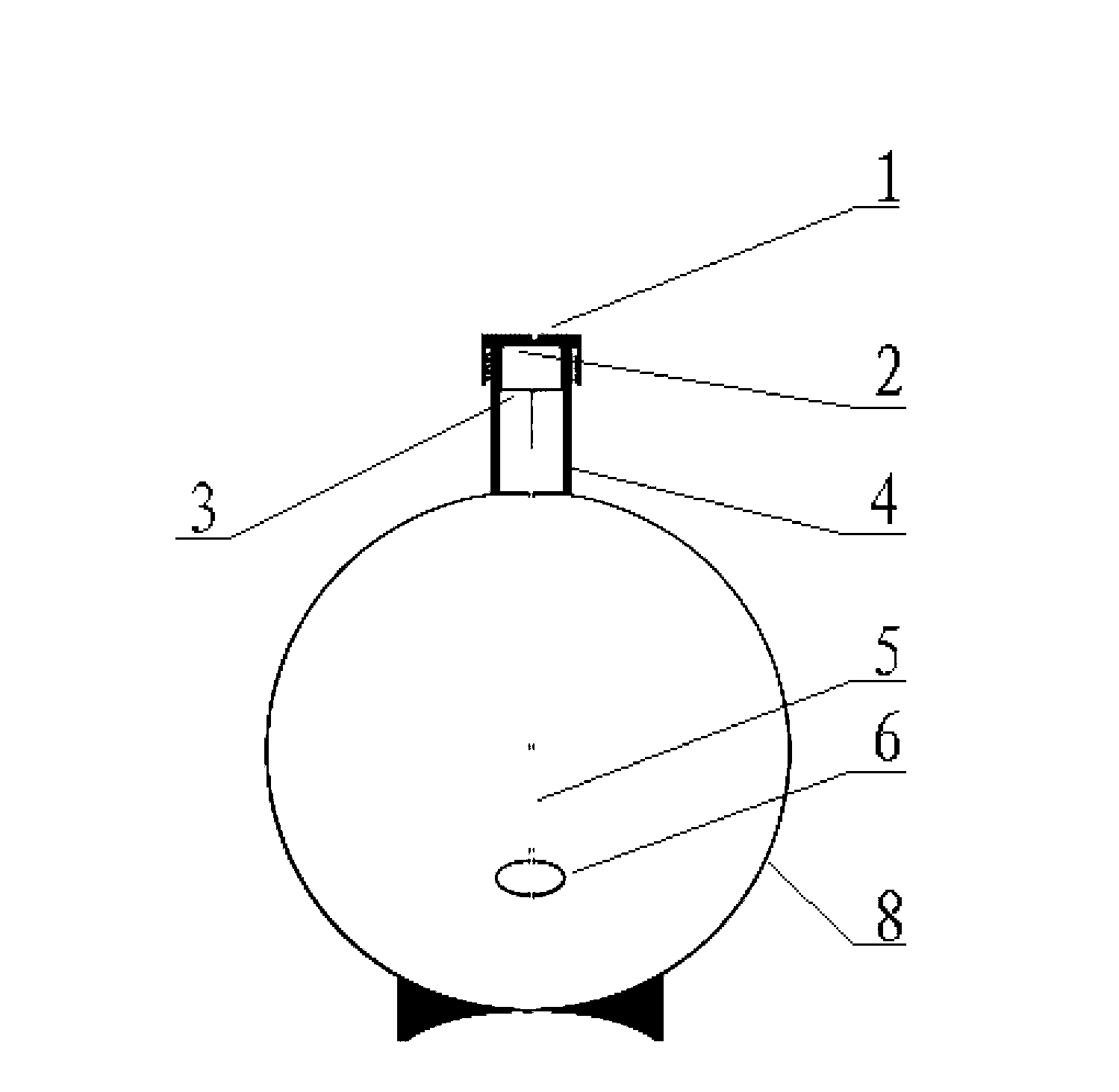

[0042] Such as figure 1 As described in -7, a liquid packaging device that is anti-upside down, anti-leakage, anti-leakage, and ventilating includes a top cover 1, a breathable gasket 2, a first inner cover 3 with a conduit, a second inner cover 4 with a conduit, and a connecting hose 5. Buoyancy ball 6, device container 8;

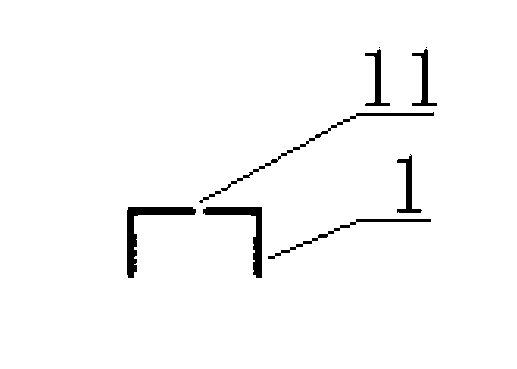

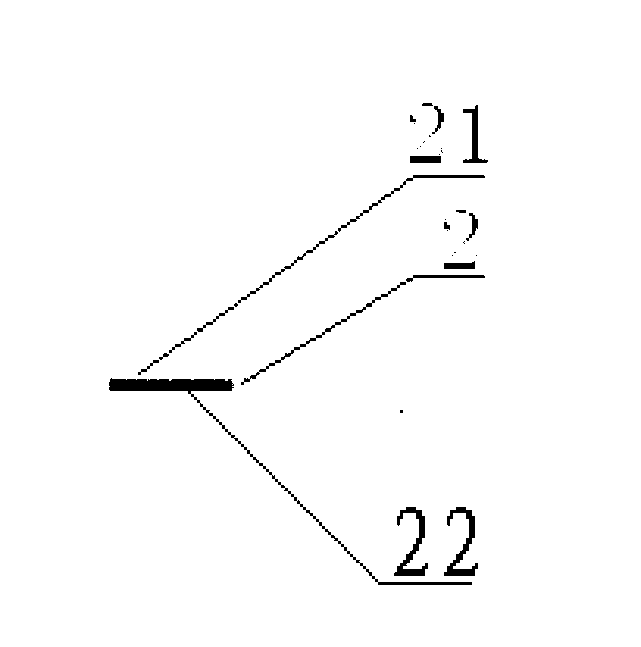

[0043] Described top cover 1 is provided with air vent 11, and device container 8 is provided with bottle mouth 81, and described air-permeable gasket 2 comprises air-permeable membrane layer 22 and the air-permeable gasket groove surface 21 that is positioned on the air-permeable membrane layer 22, and described air-permeable gasket The sheet 2 is placed in the top cover 1, the top cover air hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com