Method for improving precipitation performance of filamentous bulking sludge

A technology of bulking sludge and filamentous bacteria, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. The effect of improving sedimentation performance and effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

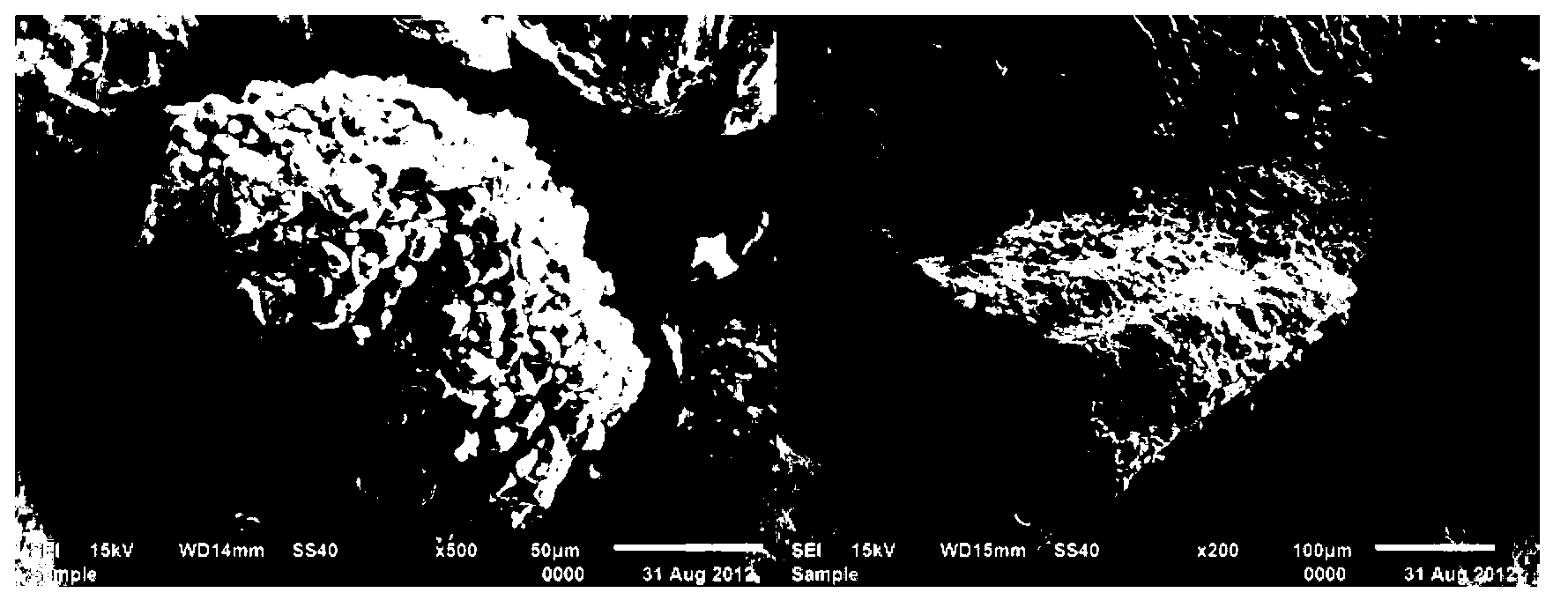

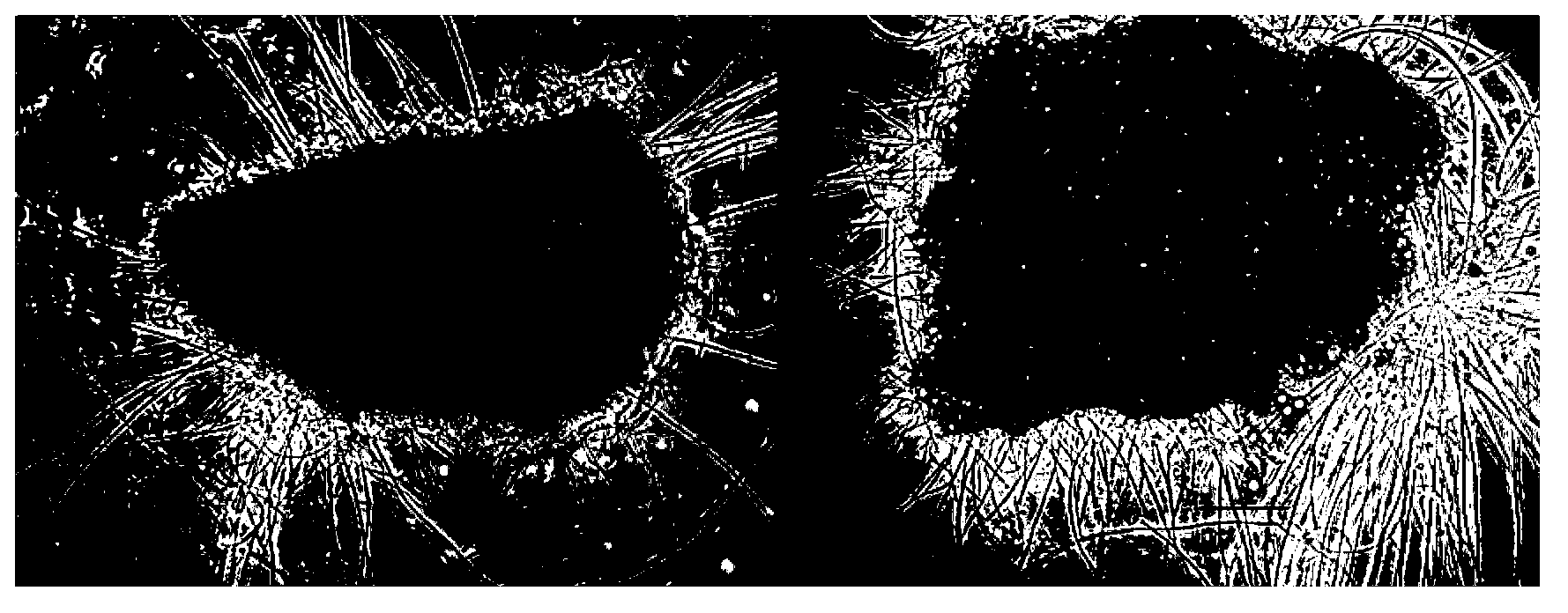

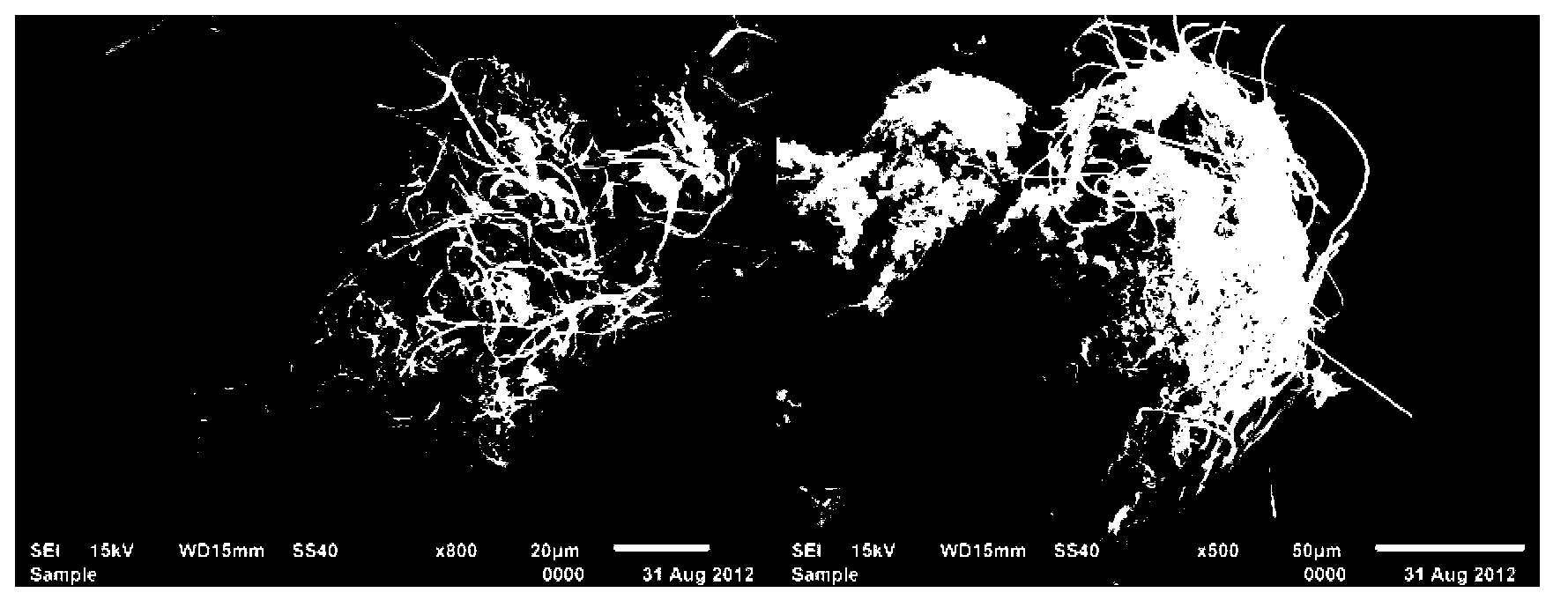

Image

Examples

Embodiment 1

[0024] A sewage treatment plant has a daily sewage treatment capacity of 100,000 m 3 / d, assume about 3km in the area 2 For the sewage treatment work in the area, the plant adopts the improved sequencing batch activated sludge method (SBR method). Design influent water quality BOD 5 180mg / L, CODcr 360mg / L, SS 250mg / L; effluent water quality BOD 5 30mg / L, CODcr 100mg / L, SS 30mg / L. During operation, sludge bulking occurred in some biological pools, and the SVI value increased significantly, and its value was around 200mL / g; the concentration of active sludge MLSS also decreased significantly, from 2500mg / L under normal conditions to 1000mg / L; Observing the sludge under a microscope, all the sludge flocs had a higher abundance of filamentous bacteria, forming a network.

[0025] The specific steps of the method for improving the sedimentation performance of filamentous bacteria bulking sludge in the present invention are as follows:

[0026] ①Crush the organic matter (corn),...

Embodiment 2

[0034] The design treatment capacity of a sewage treatment plant is 10,000 m 3 / d, the water quality is mainly domestic sewage, and contains a small amount of industrial wastewater. The sewage treatment plant adopts the oxidation ditch process. The main design parameters: the hydraulic retention time is 22.56h, the sludge age is 22.76d, the sludge load is 0.06kgBOD / (kgMLSS·d), and the settling time is 2.5h. Sludge bulking occurred during the operation of the sewage plant. During the sludge bulking, the sludge in the aeration tank turned black, the SV was as high as 98%, and the peak value of SVI reached 800mL / g. Microscopic examination found that a large number of filamentous bacteria protruded from the bacterial micelles , the quality of effluent water deteriorates.

[0035] The specific steps of the method for improving the sedimentation performance of filamentous bacteria bulking sludge in the present invention are as follows:

[0036] ① The organic matter (rice) is crush...

Embodiment 3

[0042] A sewage treatment plant in a city in northern my country, the design load is 0.24kgBOD / (kgMLSS·d), BOD 5 200-300mg / L, design flow 30,000m 3 / d, the aeration time is 8h, the sedimentation time of the secondary sedimentation tank is 2.5h, and the plug-flow operation is adopted. The actual operating load is only about 0.1kgBOD / kgMLSS·d, and the actual flow rate is 17,000m 3 / d. Since it was put into operation, swelling has occurred in winter and spring. Microscopic observation of the swelling sludge and Gram and Nessler staining tests have proved that the sludge swelling is caused by microthrix prricella of the genus Microthrix.

[0043] The specific steps of the method for improving the sedimentation performance of filamentous bacteria bulking sludge in the present invention are as follows:

[0044] ① The organic matter (wheat) is crushed, sieved with a sieve, and the wheat with a particle size of 0.2 mm is screened out;

[0045] ②The concentration of activated sludg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com