Under-shaft drilling water treatment device

A technology of water treatment device and pretreatment machine, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the problems of not having a complete drilling rig drilling circulating water treatment device, etc. , to achieve the effect of reducing the amount of storage, reducing labor intensity, and reducing the frequency of dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

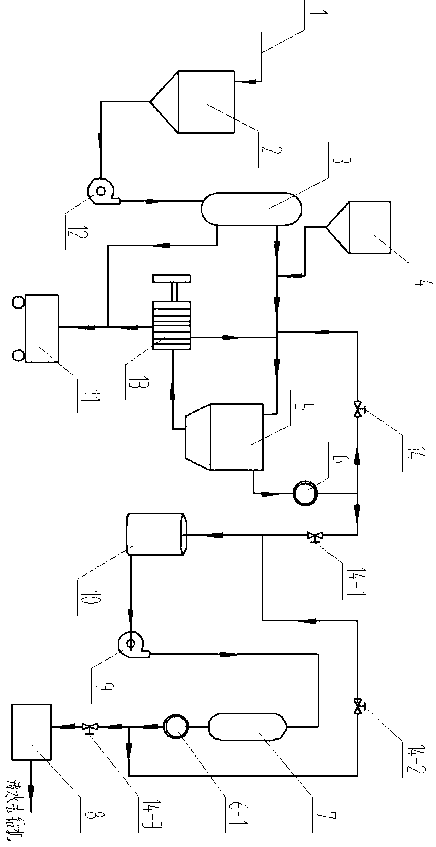

[0020] The drilling rig drills the coal slime water into the coal slime water collection tank 2 from the drilling coal slime water incoming material pipeline 1, and enters the coal slime water pretreatment machine 3 by the coal slime water collection pump 12, and intercepts and removes large particles, and the intercepted large particles enter the mine car 11, The coal slime water through the pretreatment machine 3 enters the coagulation thickener 5, and the coal slime water concentrated by the coagulation thickener 5 enters the coal slime filter press 13, and the coal slime filter cake after the pressure filtration enters the mine car 11, and is coagulated and concentrated The overflow supernatant of the machine 5 enters the water quality on-line detector 6, and after the detection of the water quality detector 6, if the water quality is up to standard, then start the valve 14-1, and close the valve 14, and the supernatant water enters the overflow water tank 10, if the water q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com