Method for sintering zirconium diboride ceramic material

A technology of ceramic materials and sintering methods, which is applied in the field of preparation of inorganic composite materials, can solve the problems of not promoting ZrB2 well and uneven dispersion of the matrix, and achieve the improvement of various properties, density and performance, and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh ZrB 2 Powder 40g, ZrC powder 5.5059g, Si powder 4.4941g, pour all the weighed materials into a ball milling tank, add alcohol and 100g of zirconia grinding balls, and mix the materials on the ball mill at 150 rpm for 4 hours. The ball-milled material is filtered and dried in a vacuum drying oven, and sieved 3 times after drying to obtain a mixed raw material mixture.

[0024] Weigh 25g of the above mixed raw material mixture, put it into a graphite mold with a diameter of 30mm, and perform spark plasma sintering in a vacuum atmosphere. The temperature is raised to 1500°C at 100°C / min, and the temperature is kept for 5 minutes, the pressure is 40MPa, and it is obtained after natural cooling. ZrB 2 -SiC-ZrSi 2 Ceramic composite material, SiC and ZrSi in the material 2 The theoretical mass percentage is 20wt%.

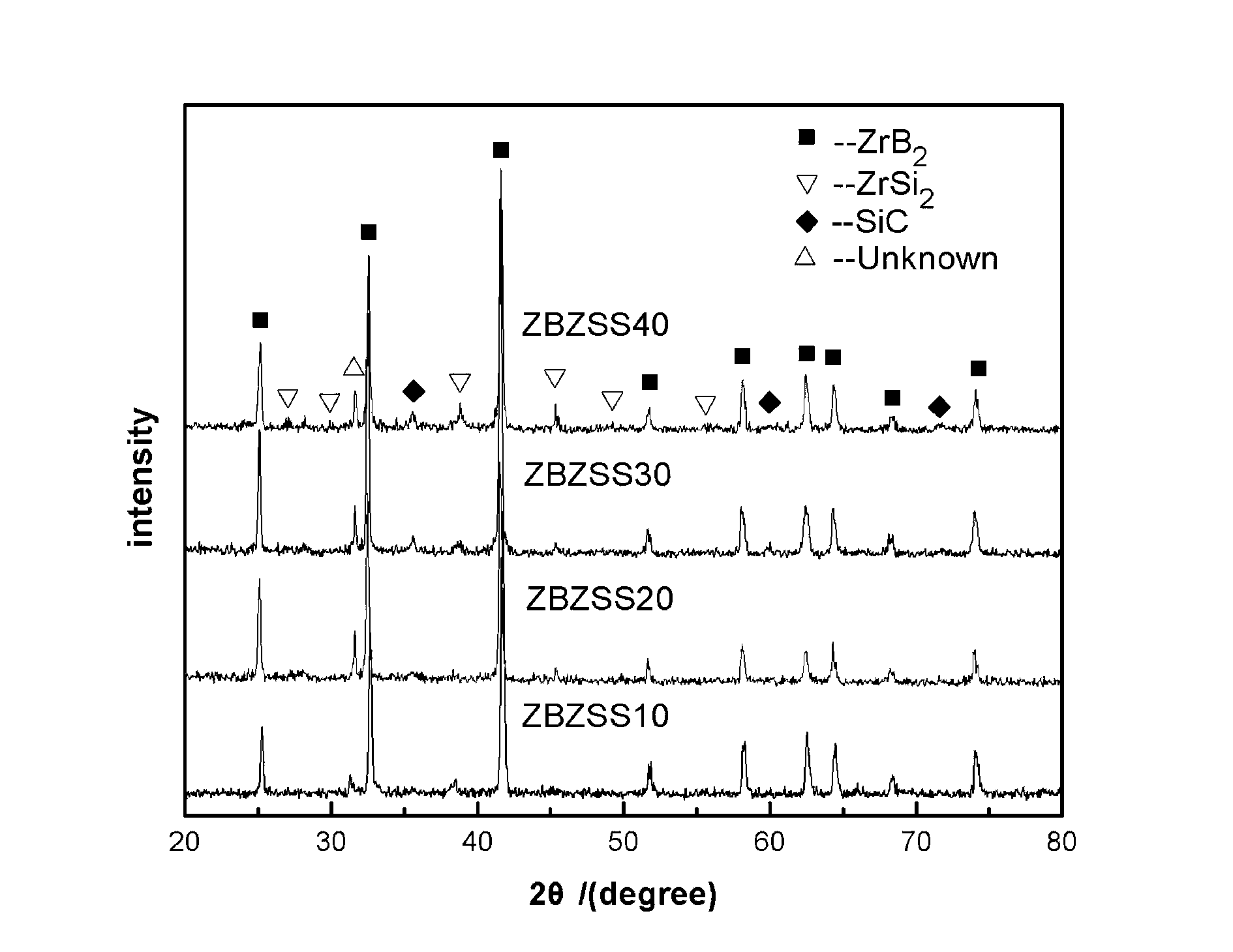

[0025] figure 1 The ZBZSS20 pattern is the XRD pattern of the sintered sample. It can be seen from the figure that except for ZrB 2 In addition to the diffraction...

Embodiment 2

[0027] Weigh ZrB 2 Powder 35g, ZrC powder 8.2588g, Si powder 6.7412g, pour all the weighed materials into a ball milling tank, add alcohol and 100g of zirconia balls, and mix the materials on a ball mill at 150 revolutions / min for 4 hours. The ball-milled material is filtered and placed in a vacuum drying box for drying, and then sieved 3 times after drying to obtain a mixed raw material mixture.

[0028] Weigh 25g of the above mixed raw material mixture, put it into a graphite mold with a diameter of 30mm, perform spark plasma sintering in a vacuum atmosphere, raise the temperature to 1500°C at 100°C / min, hold it for 10 minutes, pressure 30MPa, and cool down. ZrB 2 -SiC-ZrSi 2 Ceramic composites, SiC and ZrSi in materials 2 The theoretical mass percentage is 30wt%.

[0029] figure 1 The ZBZSS30 pattern is the XRD pattern of the sintered sample. It can be seen from the figure that except for ZrB 2 SiC and ZrSi can also be seen outside the diffraction peaks 2 The diffraction peak is...

Embodiment 3

[0031] Weigh ZrB 2 Powder 30g, ZrC powder 11.0117g, Si powder 8.9883g, pour all the weighed materials into a ball milling tank, add alcohol and 100g of zirconia balls, and mix the materials on a ball mill at 150 rpm for 4 hours. The ball-milled material is filtered and placed in a vacuum drying box for drying, and then sieved 3 times after drying to obtain a mixed raw material mixture.

[0032] Weigh 25g of the above mixed raw material mixture, put it into a graphite mold with a diameter of 30mm, perform spark plasma sintering in a vacuum atmosphere, raise the temperature to 1500°C at 100°C / min, hold for 15 minutes, pressure 20MPa, and cool down. Get ZrB 2 -SiC-ZrSi 2 Ceramic composites, SiC and ZrSi in materials 2 The theoretical mass percentage is 40wt%.

[0033] figure 1 The ZBZSS40 pattern is the XRD pattern of the sintered sample. It can be seen from the figure that except for ZrB 2 SiC and ZrSi can also be seen outside the diffraction peaks 2 Diffraction peaks, SiC and ZrSi 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com