High multi-axis impact polycarbonate composition and preparation method thereof

A polycarbonate, multiaxial impact technology, applied in the field of high multiaxial impact polycarbonate composition and its preparation, can solve the problem that there is no way to simulate the application field, etc., and achieve the effect of good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

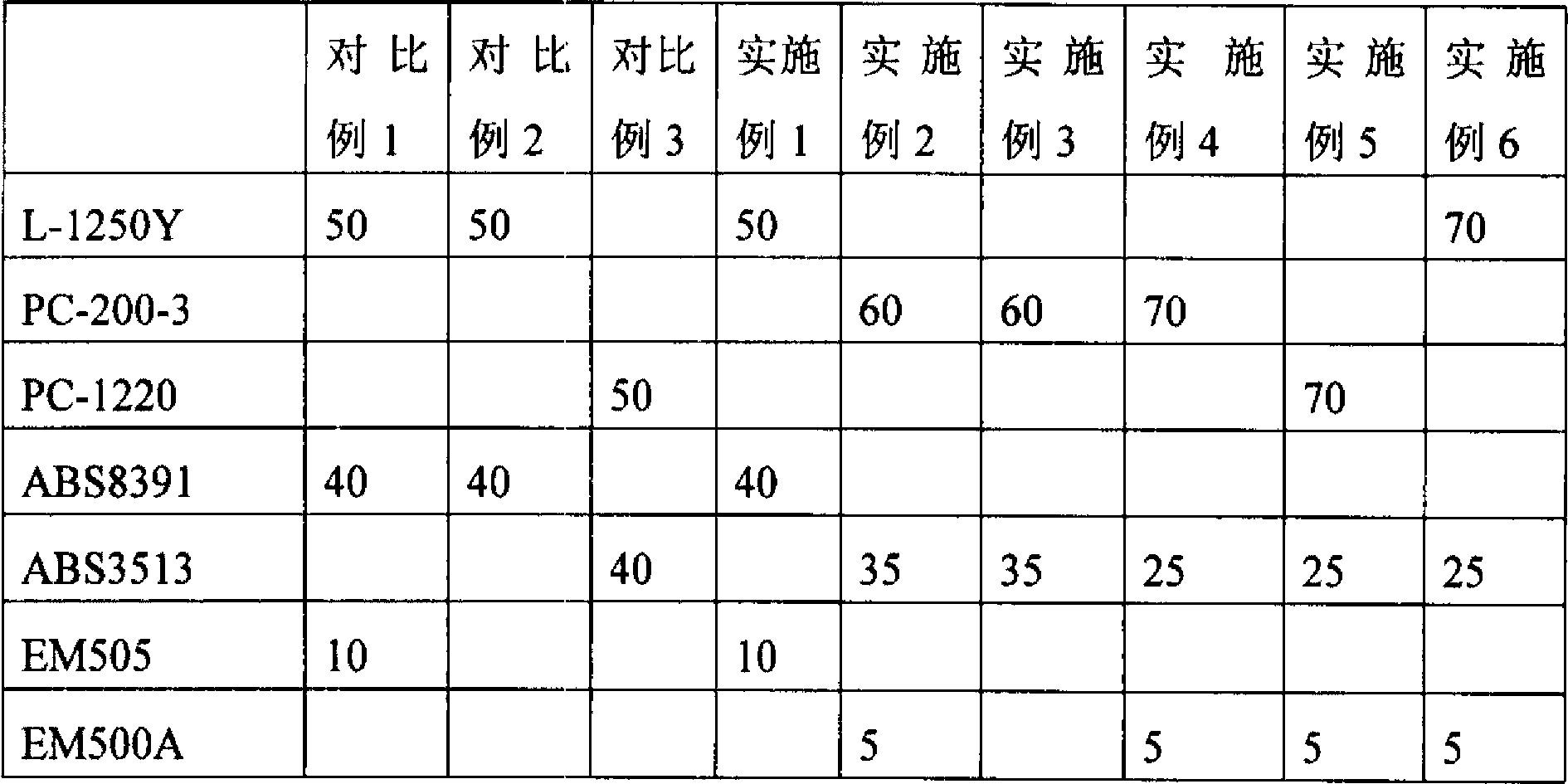

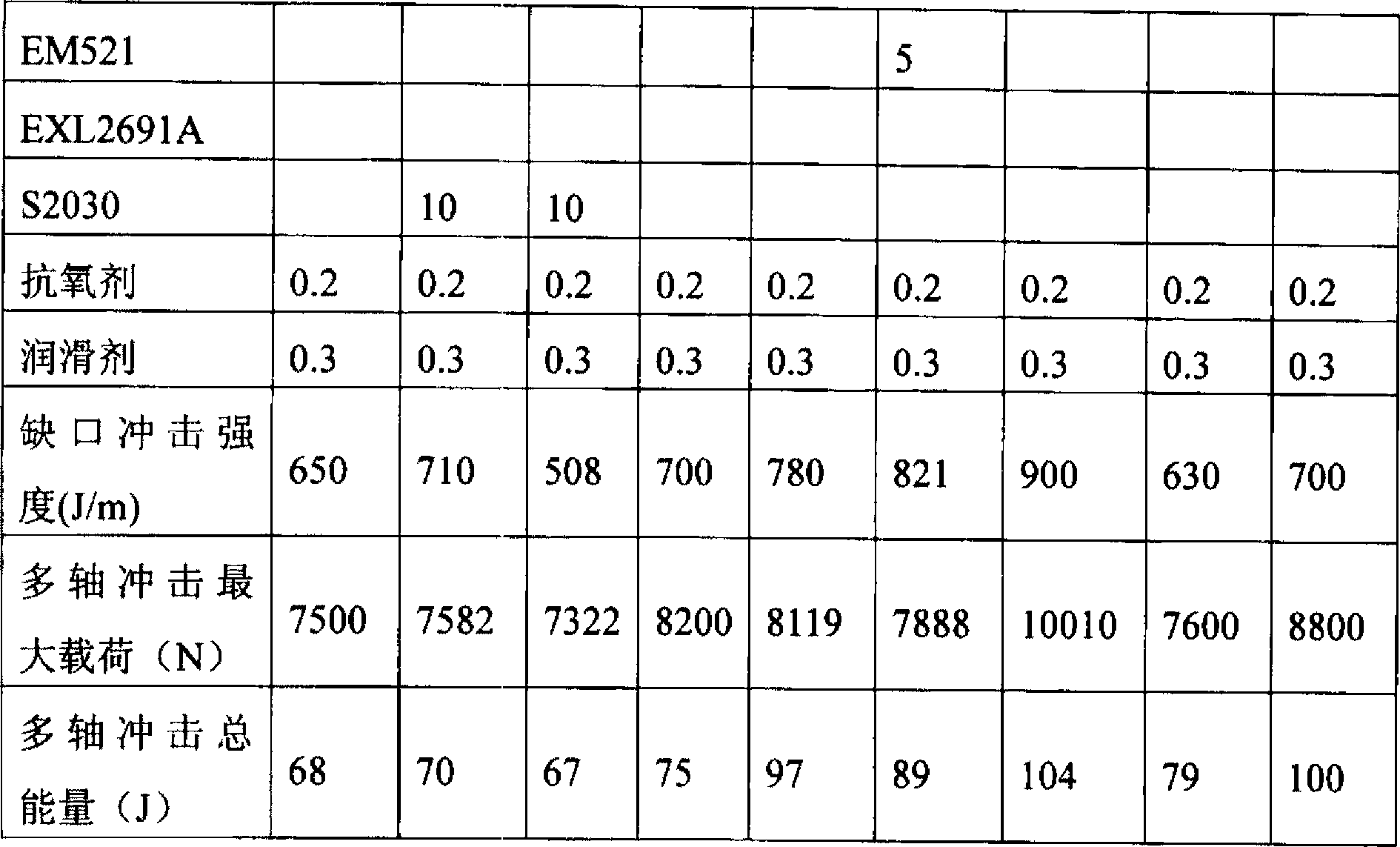

Embodiment 1

[0034] (1) Weigh each component by weight: PC is L1250Y:50, ABS is ABS839140, toughening agent EM50510, antioxidant 10100.1, antioxidant 1680.1, lubricant PETS 0.3.

[0035] (2) Divide the raw materials into two parts, part A includes PC, antioxidant, lubricant, part B includes ABS and toughening agent. Premix parts A and B separately in a high speed mixer.

[0036] (3) Add the premix into the twin-screw extruder, feed part A from the main feeding port, and feed part B from the side feeding port, melt and extrude at 200-280 ° C, screw extruder The rotational speed is 300rpm, the pressure is 2MPa, and the product is obtained through melt extrusion and granulation.

Embodiment 2

[0038] (1) Weigh each component by weight: PC is PC-200-3:60, ABS is ABS351335, toughening agent EM500A5, antioxidant 10100.1, antioxidant 1680.1, lubricant PETS 0.3.

[0039] (2) Divide the raw materials into two parts, part A includes PC, antioxidant, lubricant, part B includes ABS and toughening agent. Premix parts A and B separately in a high speed mixer.

[0040] (3) Add the premix into the twin-screw extruder, feed part A from the main feeding port, and feed part B from the side feeding port, melt and extrude at 200-280 ° C, screw extruder The rotational speed is 500rpm, the pressure is 2MPa, and the product is obtained through melt extrusion and granulation.

Embodiment 3

[0042] (1) Weigh each component by weight: PC is PC-200-3:60, ABS is ABS351335, toughening agent M5215, antioxidant 10100.1, antioxidant 1680.1, lubricant PETS 0.3.

[0043] (2) Divide the raw materials into two parts, part A includes PC, antioxidant, lubricant, part B includes ABS and toughening agent. Premix parts A and B separately in a high speed mixer.

[0044] (3) Add the premix into the twin-screw extruder, feed part A from the main feeding port, and feed part B from the side feeding port, melt and extrude at 200-280 ° C, screw extruder The rotational speed is 500rpm, the pressure is 2MPa, and the product is obtained through melt extrusion and granulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com