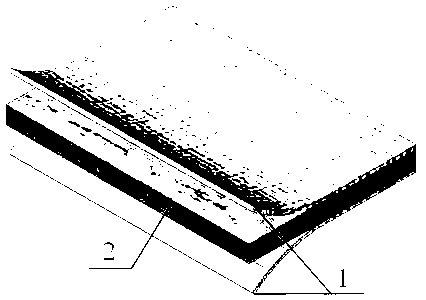

Container bottom plate and preparation method thereof

A technology of container floor and core board, applied in the field of floor, can solve the problem that it is difficult to meet the use requirements of the container floor, and achieve the effects of high production efficiency, alleviation of white pollution, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

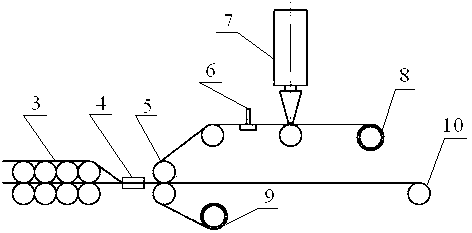

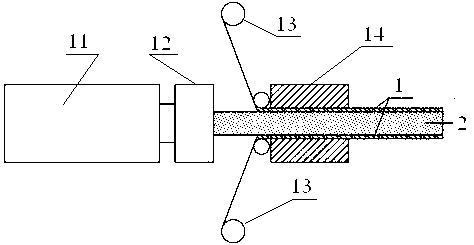

Method used

Image

Examples

Embodiment 1

[0046] The specific preparation method is as described above, and the raw materials and their mass percentages are shown in Table 1.

[0047] Table 1

[0048]

Embodiment 2

[0050] The specific preparation method is as described above, and the raw materials and their mass percentages are shown in Table 2.

[0051] Table 2

[0052]

Embodiment 3

[0054] The specific preparation method is as described above, and the raw materials and their mass percentages are shown in Table 3.

[0055] table 3

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com