Cracking/waxing/oiling treatment agent for artificial leather

A treatment agent, artificial leather technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of oily skin appearing plastic light, formula limitation, affecting leather feeling, etc., and achieve the effect of strong oil penetration, good touch, and reasonable formula design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] This example provides a cracked wax varnish skin treatment agent for artificial leather. In parts by weight, its raw material formula is as follows: 50 parts of oil skin resin, 30 parts of nitrocellulose resin, 20 parts of dimethylformamide, 10 parts of xylene, butyl 10 parts of ketone, 3 parts of simethicone, and 1 part of organomodified polysiloxane.

[0017] The preparation method of the oily skin treatment agent is: according to the formula ratio, add dimethylformamide, xylene and methyl ethyl ketone to the oily skin resin and nitrocellulose resin successively, after stirring evenly, add dimethyl silicone oil, organically modified polysiloxane Alkanes, after stirring evenly, the treatment agent is obtained. See Table 1 for the technical specifications of the treatment agent.

Embodiment 2

[0019] This example provides a kind of chapped wax varnish skin treatment agent for artificial leather, in parts by weight, its raw material formula is as follows: 48 parts of oil skin resin; 31 parts of nitrocellulose resin; 22 parts of dimethylformamide, 8 parts of xylene, butyl 8 parts of ketone, 4 parts of simethicone oil; 1 part of organomodified polysiloxane.

[0020] The preparation method of the oily skin treatment agent is: according to the formula ratio, add dimethylformamide, xylene and methyl ethyl ketone to the oily skin resin and nitrocellulose resin successively, after stirring evenly, add dimethyl silicone oil, organically modified polysiloxane Alkanes, after stirring evenly, the treatment agent is obtained. See Table 1 for the technical specifications of the treatment agent.

Embodiment 3

[0022] This example provides a kind of artificial leather cracked wax varnish skin treatment agent, in parts by weight, its raw material formula is as follows: 45 parts of oil skin resin; 35 parts of nitrocellulose resin; 25 parts of dimethylformamide, 9 parts of dimethylbenzene, butyl 8 parts of ketone, 2 parts of dimethyl silicone oil; 1.5 parts of organomodified polysiloxane.

[0023] The preparation method of the oily skin treatment agent is: according to the formula ratio, add dimethylformamide, xylene and methyl ethyl ketone to the oily skin resin and nitrocellulose resin successively, after stirring evenly, add dimethyl silicone oil, organically modified polysiloxane Alkanes, after stirring evenly, the treatment agent is obtained. See Table 1 for the technical specifications of the treatment agent.

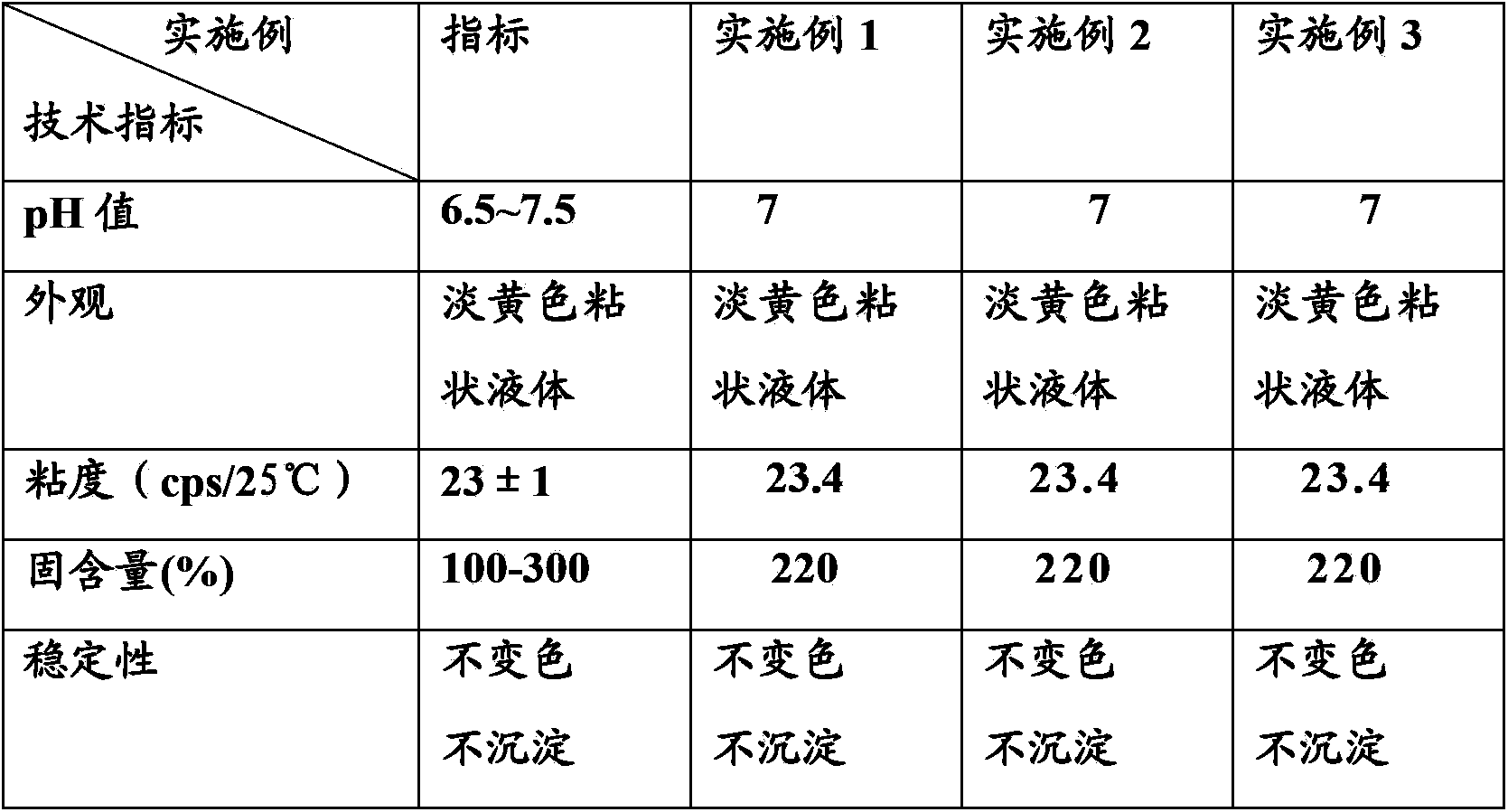

[0024] The technical index of cracked wax varnish skin treatment agent of table 1 embodiment 1~3 gained artificial leather

[0025]

[0026] The artificial leather was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com