Round steel pipe supporting structure

A support structure and round steel pipe technology, which is applied in building construction, construction, etc., can solve the problems of waste of consumption and low rigidity, and achieve the effects of steel saving, good stability, and no dead angle external area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

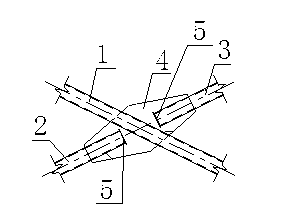

[0022] refer to figure 1 , the round steel pipe support structure of this embodiment, it comprises several round steel pipes, and the several round steel pipes are fixedly connected with each other to form the support structure.

[0023] The support structure is a pull rod structure, and the pull rod structure includes three round steel pipes, a support connecting gusset plate 4, and an arc-shaped sealing plate 5, and the round steel pipe I1 is provided with a long notch cooperating with the support connecting gusset plate 4 , the support connection gusset plate 4 passes through the round steel pipe I 1, and one end of the round steel pipe II 2 and the round steel pipe III 3 are respectively set and fixed on the two ends of the support connection gusset plate 4, and the round steel pipe II 2, the round steel pipe III 3 and the support The fixed ends of the connecting gusset plate 4 are provided with arc-shaped blocking plates 5 .

[0024] When the roof cross bracing adopts a ...

Embodiment 2

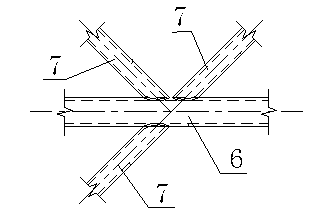

[0026] refer to figure 2 , the round steel pipe support structure of this embodiment is basically the same as the structure and working principle of Embodiment 1, the difference is that the support structure is a column-supported truss structure, and the column-supported truss structure includes a column-supported truss main pipe 6 1. Pillar truss branch pipe 7, one end of the post truss branch pipe 7 is fixedly connected to the post truss main pipe 6, and the end of the post truss branch pipe 7 connected to the post truss main pipe 6 is in the shape of an arc intersecting line.

[0027] When the support adopts a truss structure, the column-supported truss branch pipe 7 and the column-supported truss main pipe 6 can be welded intersectingly, and a plasma intersecting line cutting machine is used to cut out an intersecting arc at the end of the One end of the truss branch pipe 7 is welded on the pillar-supported truss main pipe 6 . This method can also be used for intersectin...

Embodiment 3

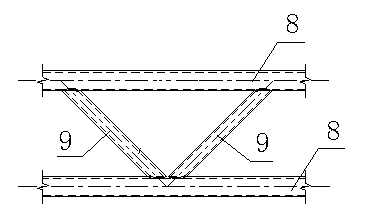

[0029] refer to figure 2 , the round steel pipe supporting structure of this embodiment is basically the same as the structure and working principle of Embodiment 1, the difference is that the supporting structure is a double-piece supporting main pipe structure, and the double-piece supporting main pipe structure includes a pair of supporting The main pipe 8 and the web bar 9 are fixedly arranged between a pair of supporting main pipes 8, and the two ends of the web bar 9 are arc-shaped intersecting lines.

[0030] When the support adopts a double-piece type, the support pipe can be connected with a thinner tube as the web bar 9. Use a plasma intersecting line cutting machine to cut out intersecting arcs at the two ends of the web bar 9, and use the surrounding welding method to weld the support tube 8. 9 groups of web bars are welded vertically. When the support adopts a truss structure, this method can also be used for intersecting welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com