Efficient energy-saving device for fuel engine

A high-efficiency and energy-saving technology for fuel engines, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of uneven flashover of each cylinder, insufficient endurance, fuel waste, etc., to achieve strong explosion power, less oil consumption, high ignition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

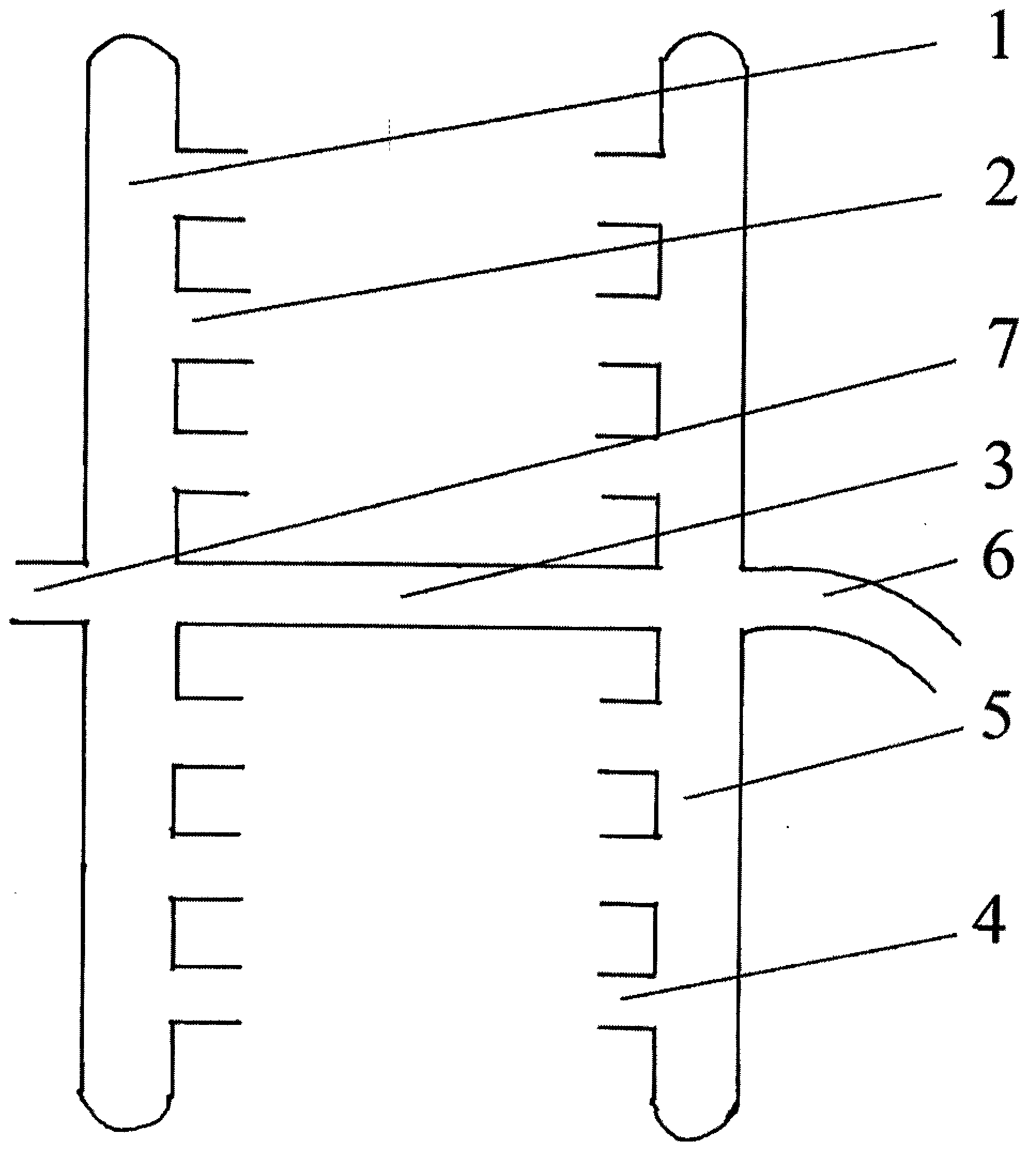

[0008] Referring to the accompanying drawings, a hole is respectively opened in the corresponding place between the total intake pipe 1 and the total exhaust pipe 5 of the six-cylinder fuel engine between the third cylinder and the fourth cylinder, and the connecting pipe 3 is used to connect these two holes, which makes the cost Invented high-efficiency energy-saving device for fuel engines.

[0009] When the fuel engine is working, the air enters the intake inlet 2 of each cylinder from the total intake port 7 through the total intake pipe 1, and then is discharged from the exhaust outlet 4 of each cylinder to the total exhaust pipe 5, and then enters the total intake through the connecting pipe 3. The air pipe 1 reciprocates in this way, so that the main intake pipe 1 absorbs a large amount of high-temperature and high-heat gas discharged from the main exhaust pipe into each piston cylinder, and becomes a high-quality fuel with a high ignition point, less oil consumption, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com