Sliding bearing type wind driven generator unit yaw system and friction plate replacement method

A technology of wind turbines and sliding bearings, which is applied in the direction of wind turbine components, wind engines, wind engine control, etc., can solve the problem of high cost of rolling yaw bearings, and achieve easy installation and replacement, simple and fast replacement, and low cost Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

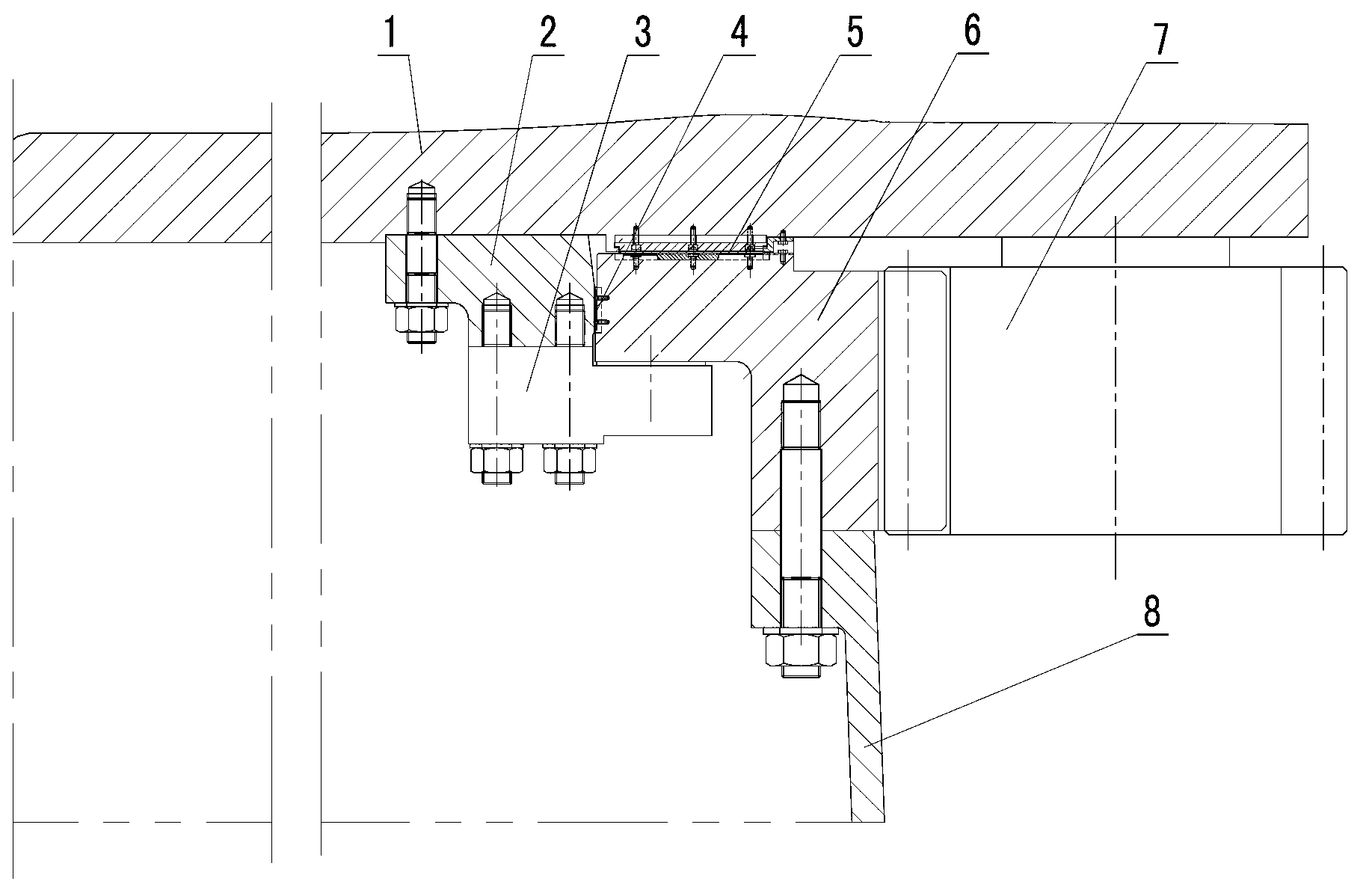

[0031] like figure 1 As shown, a sliding bearing type wind turbine yaw system of the present invention is used to connect the wind turbine tower 8 and the frame 1, and its sliding bearing adopts an external drive form. The yaw system includes a large bearing ring gear 6, a bearing inner Ring 2, bearing axial bearing surface friction plate 5, bearing radial bearing surface friction plate 4, yaw brake 3 and yaw drive mechanism 7, wherein: the lower end of the bearing large ring gear 6 is connected with the upper end of the tower 8, and its upper end The lower end of the frame 1 is supported by the bearing axial bearing surface friction plate 5 connected with it in combination, the large gear on the outer side meshes with the yaw drive mechanism 7 fixed on the frame 1, and the upper inner side is connected with the bearing diameter by the combination. The friction plate 4 on the bearing surface cooperates and slides with the outer circumference of the bearing inner ring 2; the up...

Embodiment 2

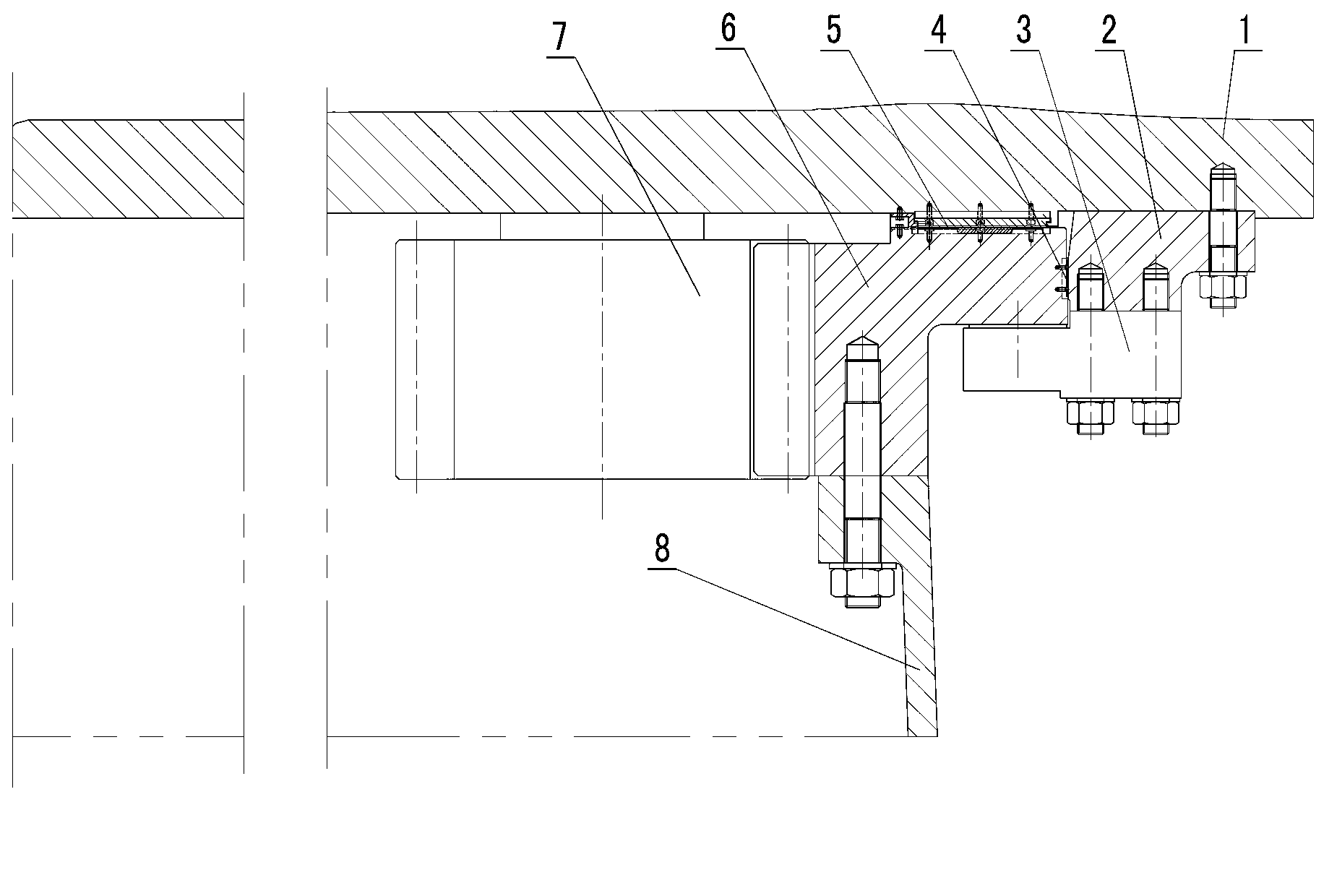

[0045] like figure 2 As shown, a sliding bearing type wind turbine yaw system of this embodiment is different from Embodiment 1 in that the sliding bearing adopts an internal drive structure, that is, the inner bearing ring is replaced with an outer bearing ring. . Both work the same way.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com