Method and system for calibrating laser beam analyzer

A technology of laser beam analysis and calibration system, which is applied in the field of laser beam analyzer calibration method and system, to achieve the effect of solving the problem of traceability, easy operation and good value reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

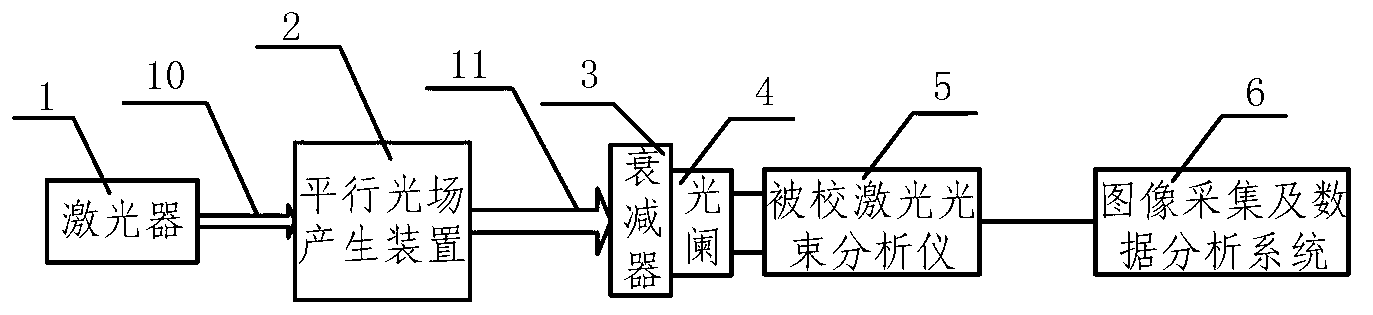

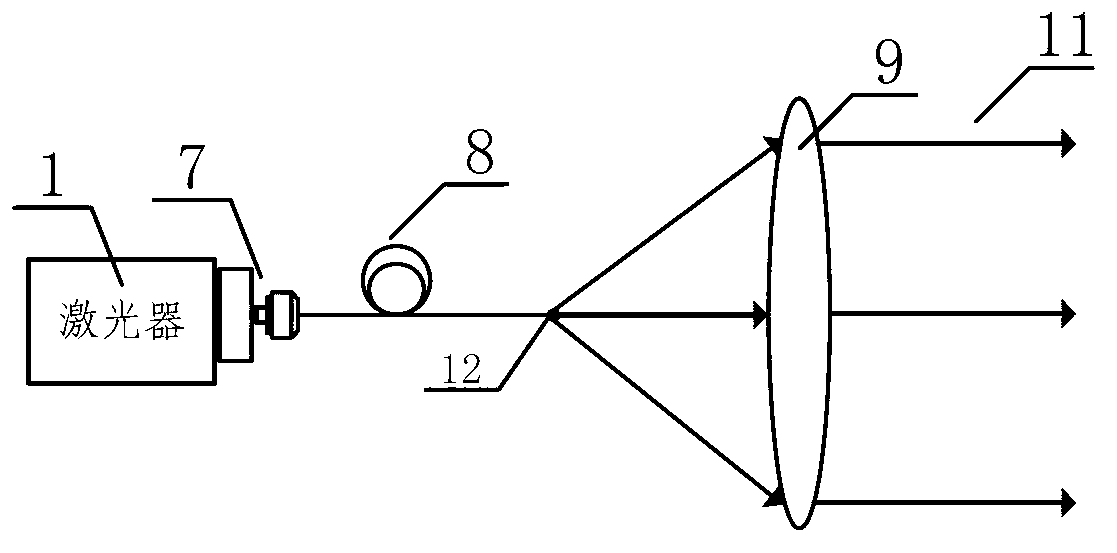

[0033] figure 1 Shown is a schematic diagram of the composition of the laser beam profiler calibration system in the embodiment of the present invention. like figure 1 As shown, the laser beam profiler calibration system in the embodiment of the present invention includes a laser 1 , a parallel light field generating device 2 , an attenuator 3 , a diaphragm 4 with a standard aperture, and a laser beam profiler 5 to be calibrated. In order to reduce the effect of diffraction, the diaphragm 4 must be close to the sensing surface of the detector of the laser beam analyzer 5 to be calibrated; the parallel light field generating device 2 is used to shape the laser beam 10 emitted by the laser 1 into a parallel beam field 11 , to obtain a parallel beam for calibration; in order to make the power density of the incident laser not exceed the damage threshold or working range of the detector of the laser beam analyzer 5 to be calibrated, the obtained parallel beam needs to be attenuat...

Embodiment 2

[0042] On the basis of the first embodiment of the laser beam analyzer calibration system, the embodiment of the present invention also provides a laser beam analyzer calibration method, including the following steps:

[0043] S1. The laser beam emitted by the laser is shaped into a parallel beam field by a parallel light field generating device;

[0044] Specifically, turn on the laser, preheat it, and make the laser enter a stable working state. The laser beam emitted by the laser is shaped by a parallel light field generating device to construct a parallel beam field.

[0045] S2. After the parallel beam is attenuated by an attenuator, it passes through a diaphragm with a standard aperture to form a flat-top beam with a standard beam width, wherein the propagation direction of the parallel beam is parallel to the normal of the diaphragm direction, and the field radius of the parallel light beam is larger than the radius of the diaphragm;

[0046]In order to make the power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com