Method for improving measurement accuracy of oxygen content in boiler flue gas

A technology for flue gas oxygen content and measurement accuracy, which is applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., and can solve problems such as the difficulty of excess air coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

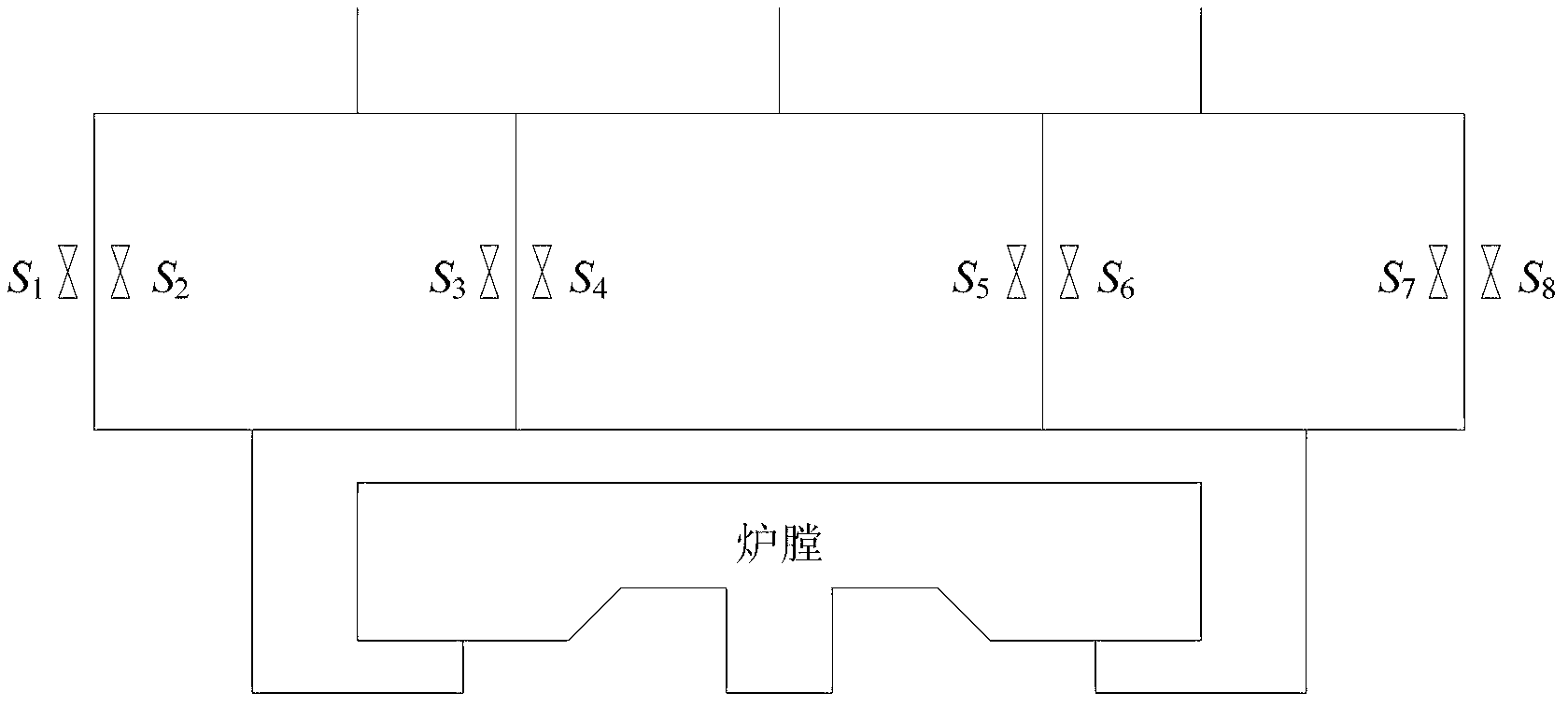

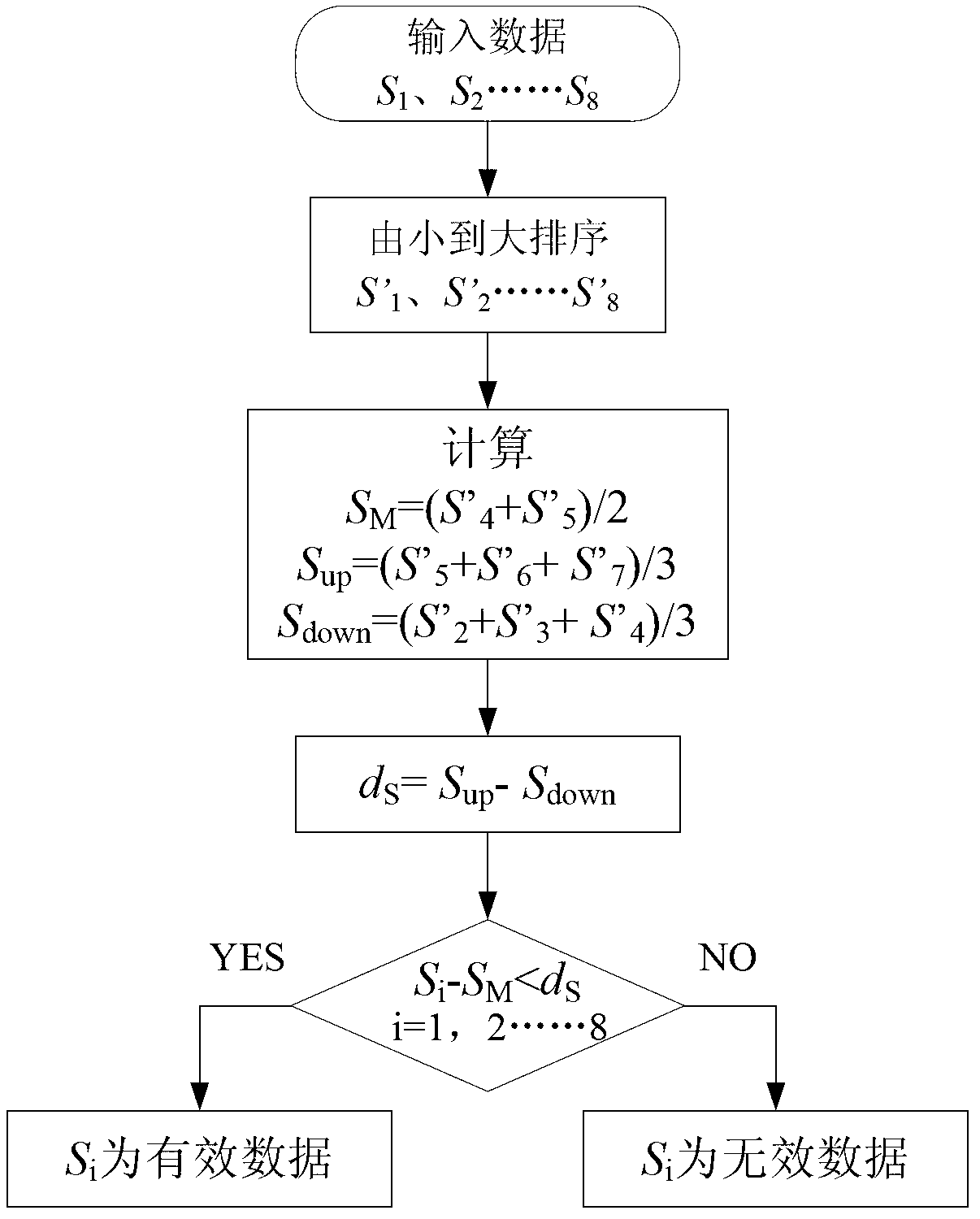

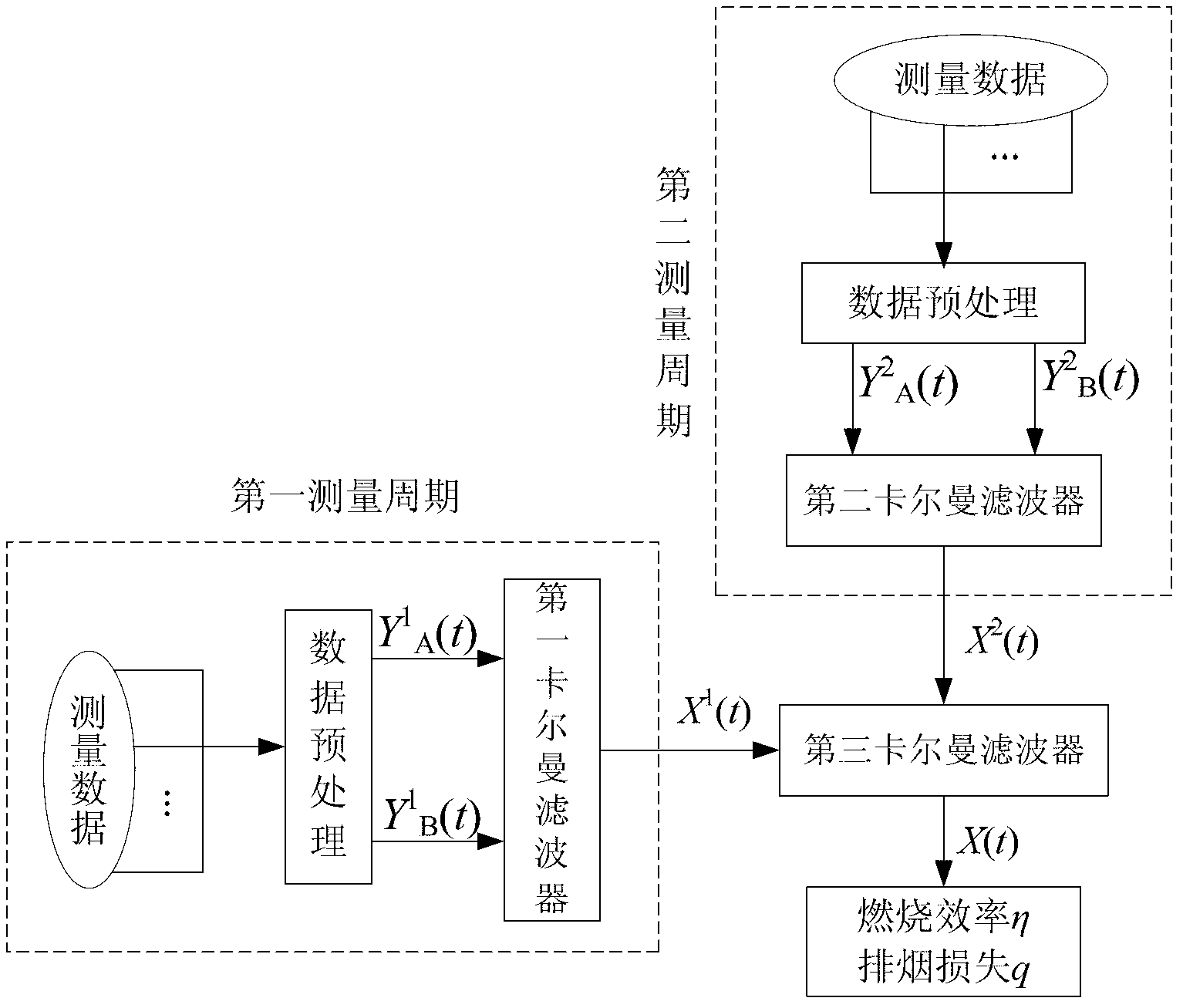

[0046] figure 1 It is a schematic diagram of the layout of the zirconia oxygen meter for a method of improving the measurement accuracy of the oxygen content of the boiler flue gas provided by the present invention. figure 1 Medium, S 1 , S 2 ... S 8 Zirconia oxygen sensor for placement. The flue gas produced by combustion is discharged from the furnace through the air preheater, dust collector and induced draft fan. In order to accurately reflect the oxygen content of the flue gas, samples are installed on both sides of the flue gas inlet of each air preheater. Each boiler has 4 air preheaters, and a total of 8 zirconia oxygen meters S 1 ,S 2 ,...,S 8 . Because the 8 zirconia oxygen meters are located in diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com