Terahertz wave polarization beam splitter of crossed F-shaped structure

A polarization beam splitter and terahertz technology, applied in the field of terahertz beam splitters, can solve the problems of low polarization beam splitting ratio, difficult manufacture, complex structure, etc., and achieve low cost, high beam splitting ratio, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

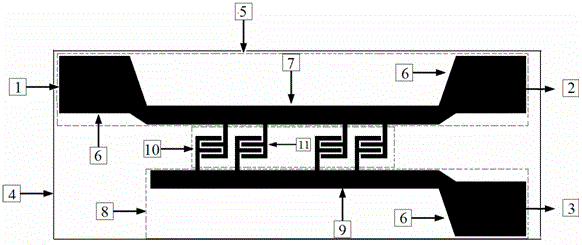

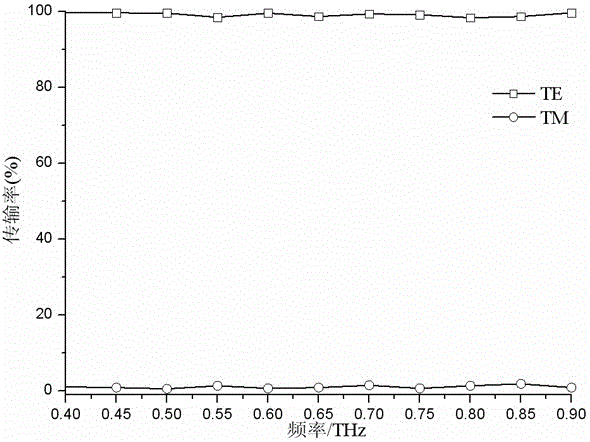

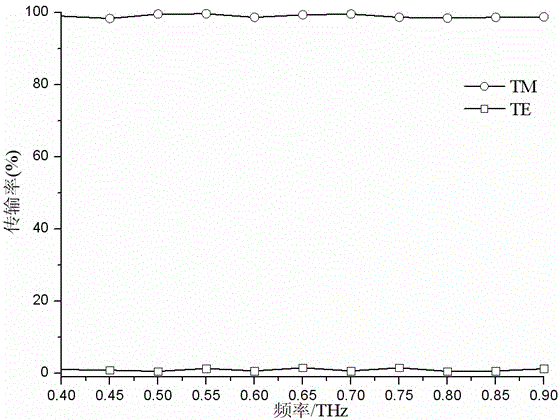

[0015] The length of the substrate is 2200 μm, the width is 700 μm, and the thickness is 100 μm. The irregular waveguide is composed of a rectangular waveguide and a right-angled triangle waveguide. The length of the rectangular waveguide is 180 μm, the width is 100 μm, and the thickness is 50 μm. The length of the bottom side of the right-angled triangle waveguide is 80 μm, and the height is 100 μm. The waveguides of the symmetrically connected waveguides have a length of 1600 μm, a width of 60 μm, and a thickness of 50 μm. The length of the asymmetrically connected coupling waveguide is 1300 μm, the width is 60 μm, and the thickness is 50 μm. The crossed F-shaped coupling coupling waveguide is composed of positive F-shaped waveguides and inverted F-shaped waveguides of equal size. The width of the F-shaped waveguide is 15 μm, the total height of the waveguide is 80 μm, and the total width of the waveguide is 60 μm. The transmission curves of TE wave and TM wave at the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com