Hybrid direct-current circuit breaker

A DC circuit breaker, hybrid technology, applied in high-voltage air circuit breakers, circuits, high-voltage/high-current switches, etc., can solve problems such as limited rated carrying capacity, dielectric breakdown between contacts, and uncontrollable contact opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

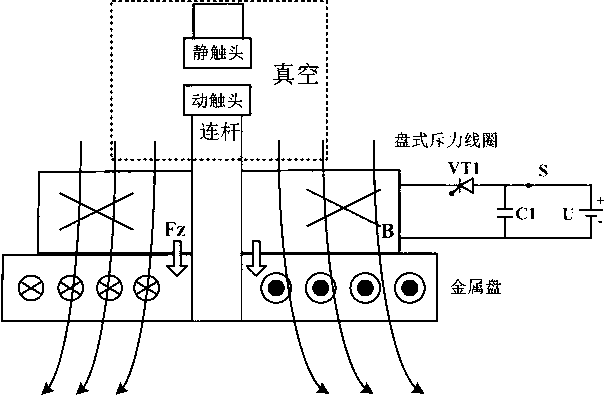

[0019] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

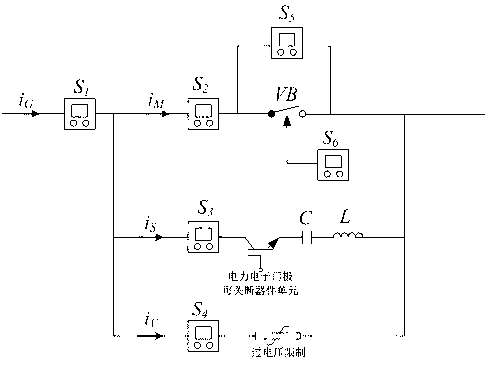

[0020] In one embodiment, such as figure 2 As shown, the hybrid DC circuit breaker includes a high-speed vacuum switch VB, an LC forced transfer circuit, an overvoltage limiting circuit, and a control system, wherein the high-speed vacuum switch VB, the LC forced transfer circuit, and an overvoltage limiting circuit are connected in parallel.

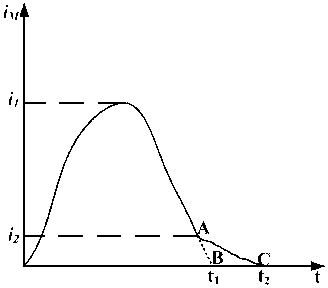

[0021] still refer to figure 2 , the LC forced transfer circuit is composed of a precharge capacitor C, an inductor L and a power electronic gate turn-off device connected in series. Under normal working conditions, the current flows through the high-speed vacuum switch VB, and a certain voltage is charged on the pre-charge capacitor C, and the direction of the voltage is opposite to the direction of the switch conduction voltage drop of the power electronics gate that can be turned off. The de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com