Electrolyte solution capable of improving high temperature cycling and storing performances of lithium secondary battery

A lithium secondary battery, high temperature cycle technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of reduced electrochemical performance, safety risks, and reduced cycle performance of lithium secondary batteries, etc. Achieve the effect of improving high temperature cycling and storage characteristics, improving contact interface, and overcoming the rapid loss of storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

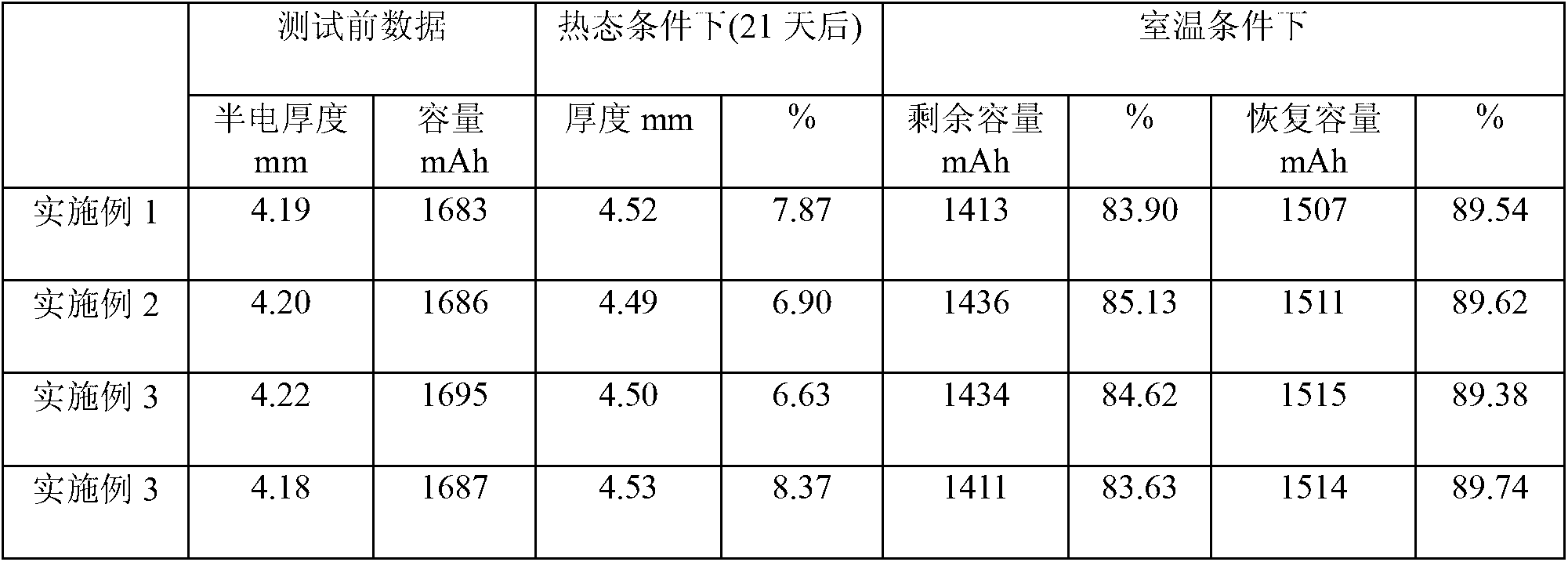

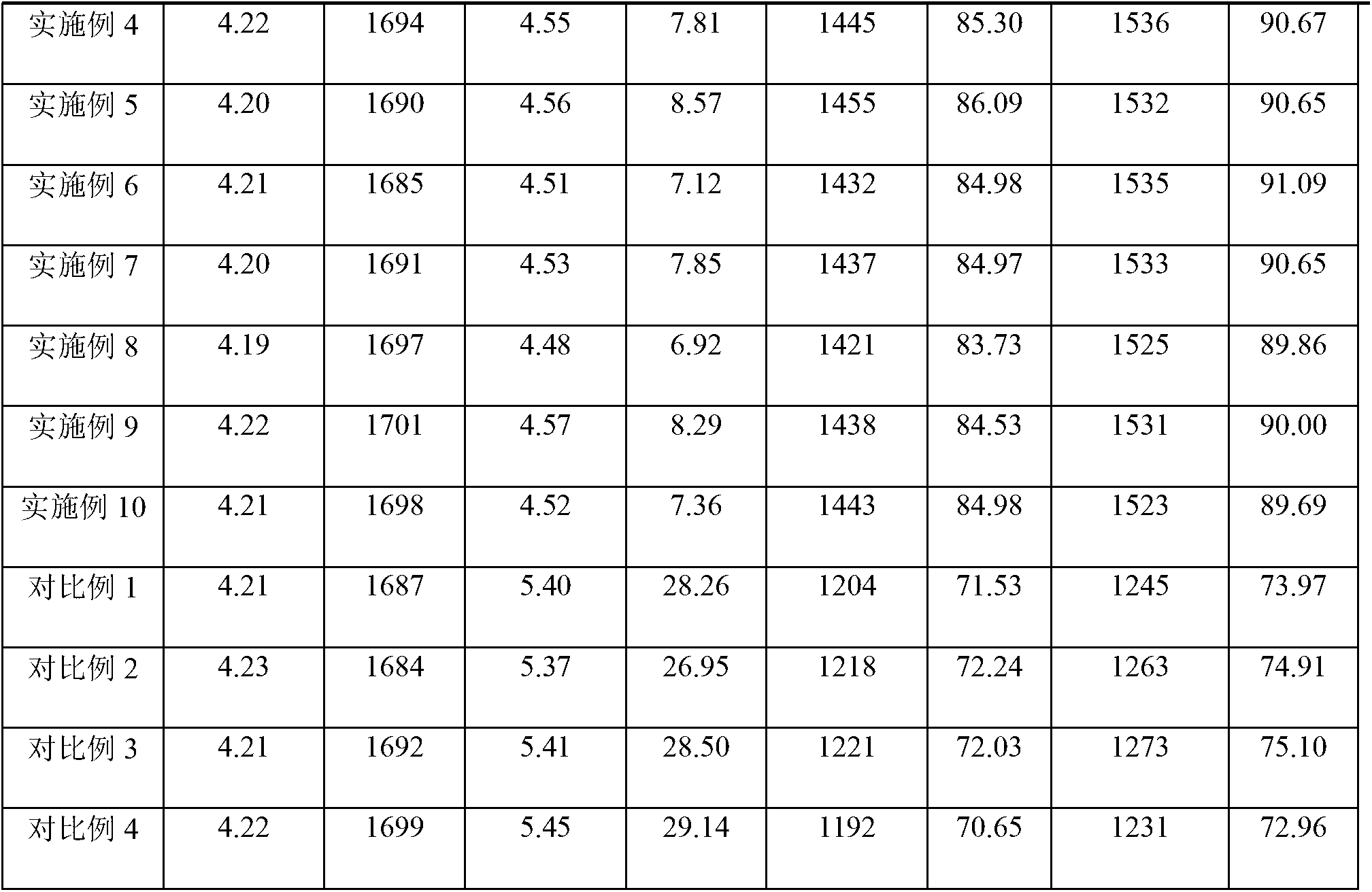

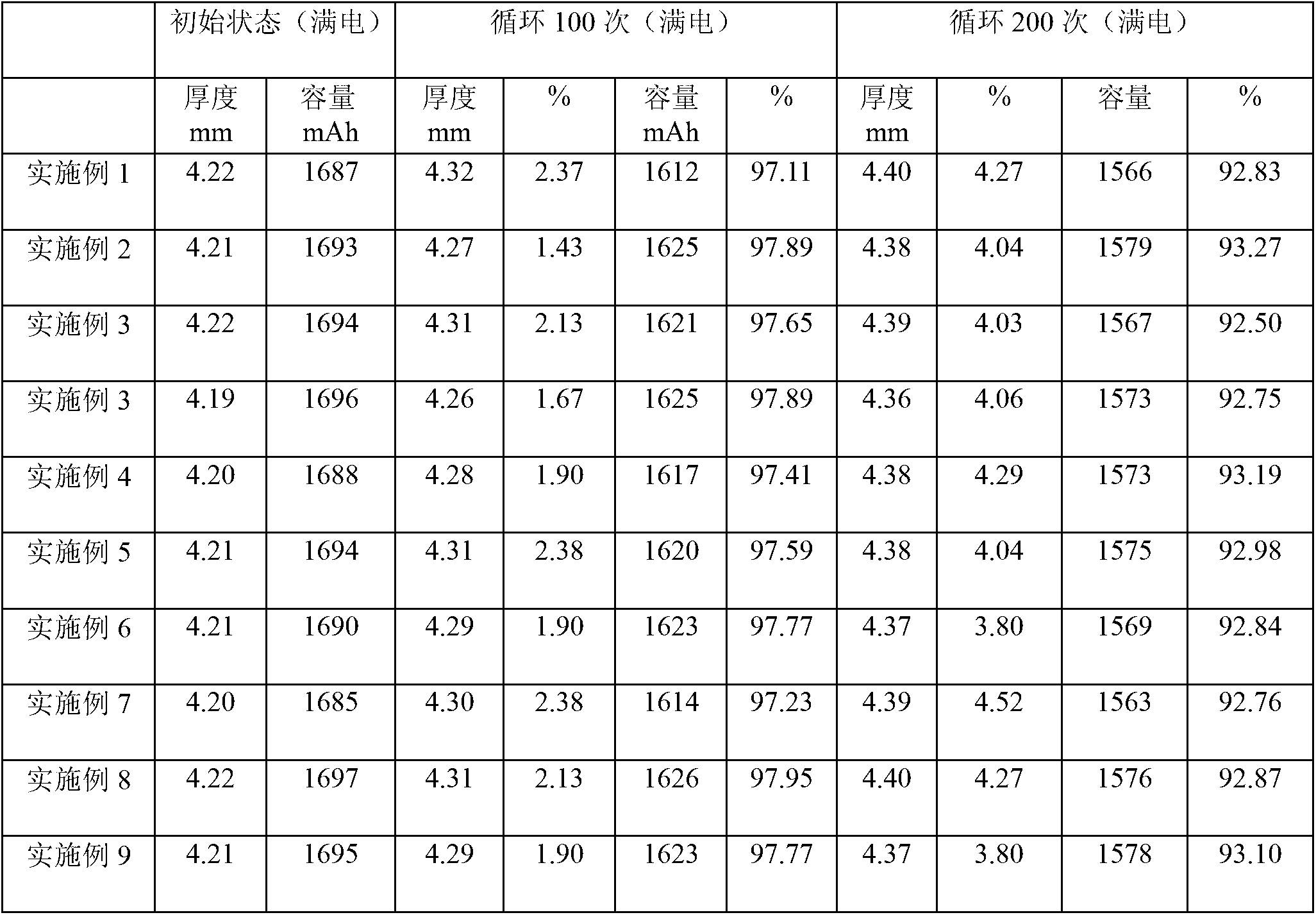

Examples

Embodiment 1

[0016] The composition and parts by mass of the electrolyte are as follows: Lithium hexafluorophosphate accounts for 10.0% by mass of the total electrolyte, and ethylene carbonate, ethyl methyl carbonate, and propylene carbonate account for 10.0% by mass of the total electrolyte. 21.0%, 42.5%, and 21.0%, respectively, the mass percentage of vinylene carbonate in the total electrolyte solution is 0.5%, and the mass percentage of δ-valerolactone in the total electrolyte solution is 5.0%.

Embodiment 2

[0018] The composition of the electrolyte is as follows: Lithium tetrafluoroborate accounts for 12.0% by mass of the total electrolyte, and ethylene carbonate, ethyl methyl carbonate, and propylene carbonate account for 20.5% by mass of the total electrolyte. , 41.0%, 20.5%, 1,3-propane sultone accounted for 1.0% by mass of the total electrolyte, and γ-valerolactone accounted for 5.0% by mass of the total electrolyte.

Embodiment 3

[0020] The composition of the electrolyte is as follows: Lithium hexafluorophosphate and lithium tetrafluoroborate account for 5.0% and 5.0% by mass of the total electrolyte, and ethylene carbonate, ethyl methyl carbonate, and propylene carbonate account for 100% by mass of the total electrolyte. The contents are 20.5%, 41.0%, 20.5% respectively, 1,3-propane sultone accounts for 1.0% of the total electrolyte, and fluoroethylene carbonate accounts for 1.0% of the total electrolyte. 2.0%, γ-caprolactone accounts for 5.0% by mass of the total electrolyte solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com