Switched reluctance motor of cast-aluminum rotor structure

A technology of switched reluctance motors and cast aluminum rotors, applied in the direction of magnetic circuit shape/style/structure, electric components, electrical components, etc., can solve the problems of low motor power density, large noise and vibration, low power factor, etc., to achieve Improve power output density and effective material utilization, reduce vibration and noise, reduce weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

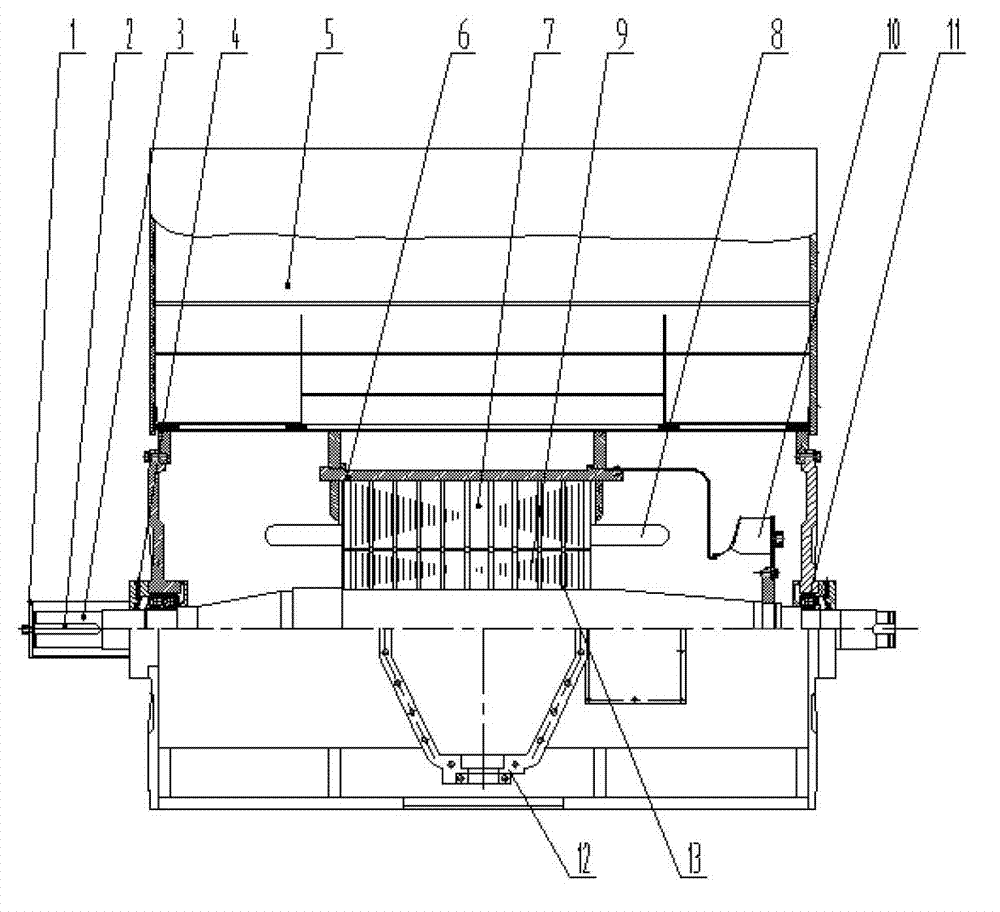

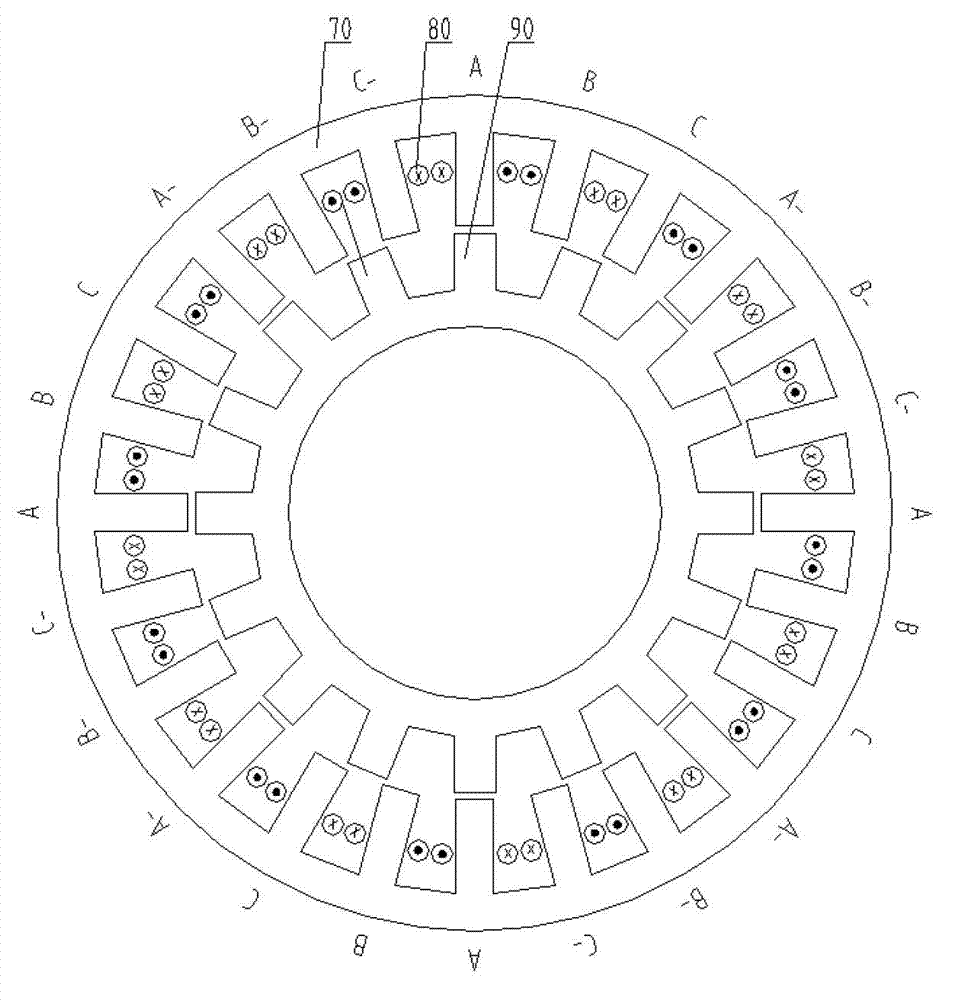

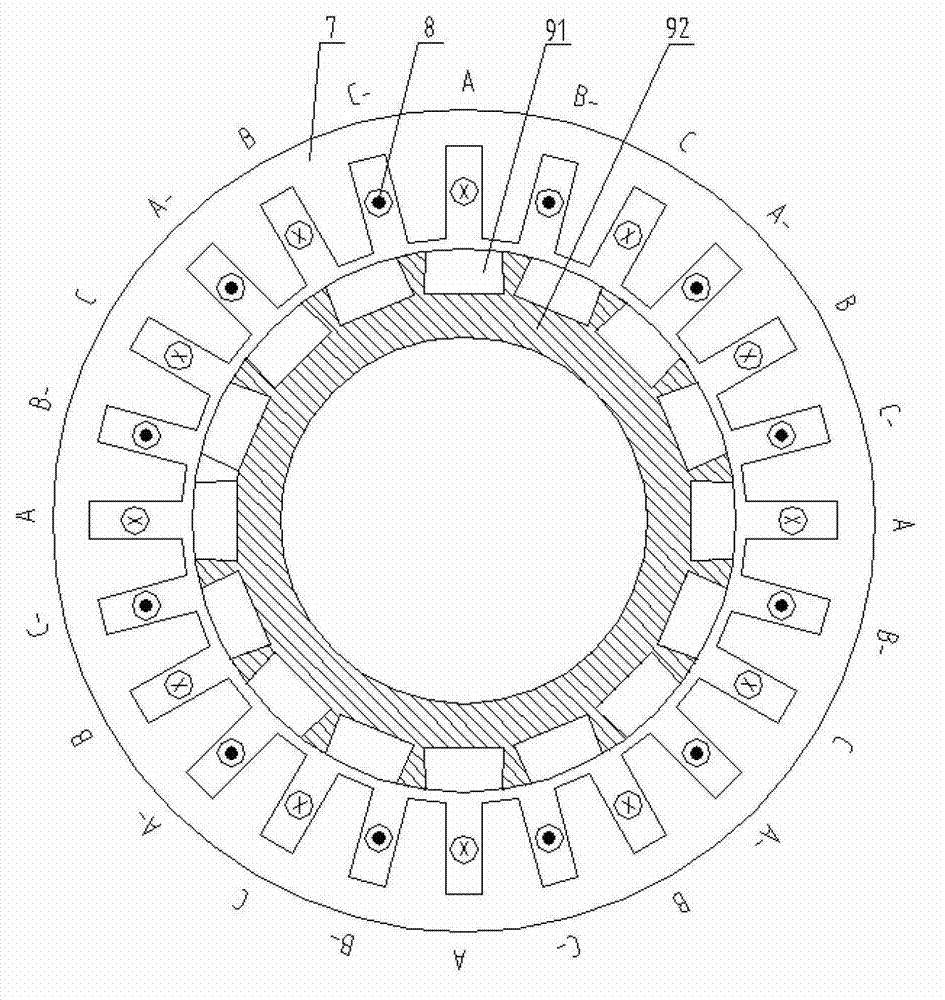

[0030] Please refer to figure 1 As shown, taking the 24 / 16 three-phase switched reluctance motor as an example, the switched reluctance motor with cast aluminum rotor structure of the present invention includes a casing 6, a rotating shaft 3, a stator core 7, a stator winding 8 and a rotor core 9, It can also include a shaft extension protective cover 1, a key 2, a front bearing assembly 4, a cooling fan 5, a cooling fan 10, a rear bearing assembly 11, a motor outlet box 12, and a cooling air duct 13.

[0031] Below to figure 1 The left end shown is the front end, and the structural composition of the generator of the present invention is described.

[0032] The rotating shaft 3 runs through the housing 6 and is rotatably connected to the housing 6 through the front bearing assembly 4 and the rear bearing assembly 11 . The rotor core 9 is installed on the rotating shaft 3 and is located between the front bearing assembly 4 and the rear bearing assembly 11 . The stator core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com