Electromagnetic coil structure having a flat conductive track, magnetic core and megneto electronic angle sensor

An angle sensor, electromagnetic coil technology, applied in the field of magnetoresistive resolver, manufacturing such angle sensor, can solve problems such as failure, to achieve the effect of reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

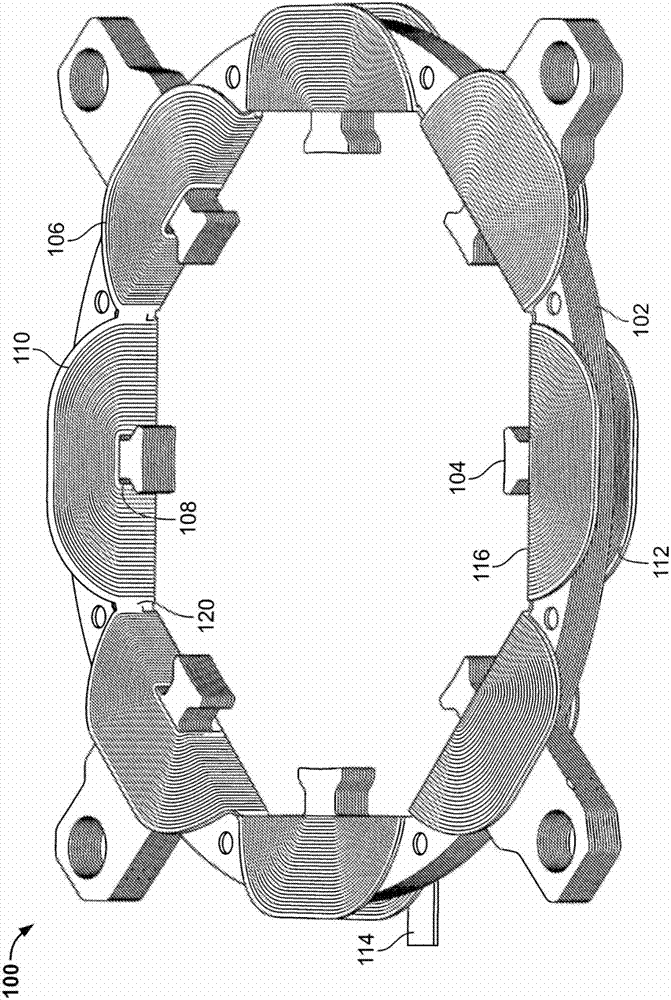

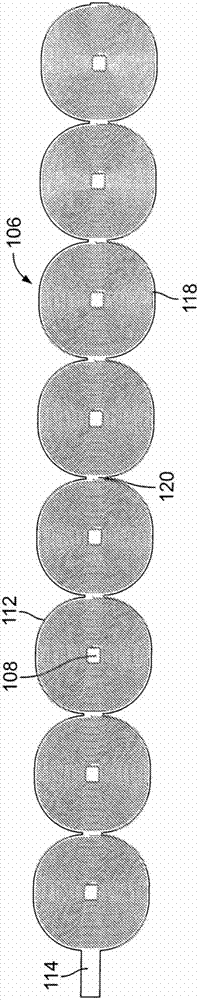

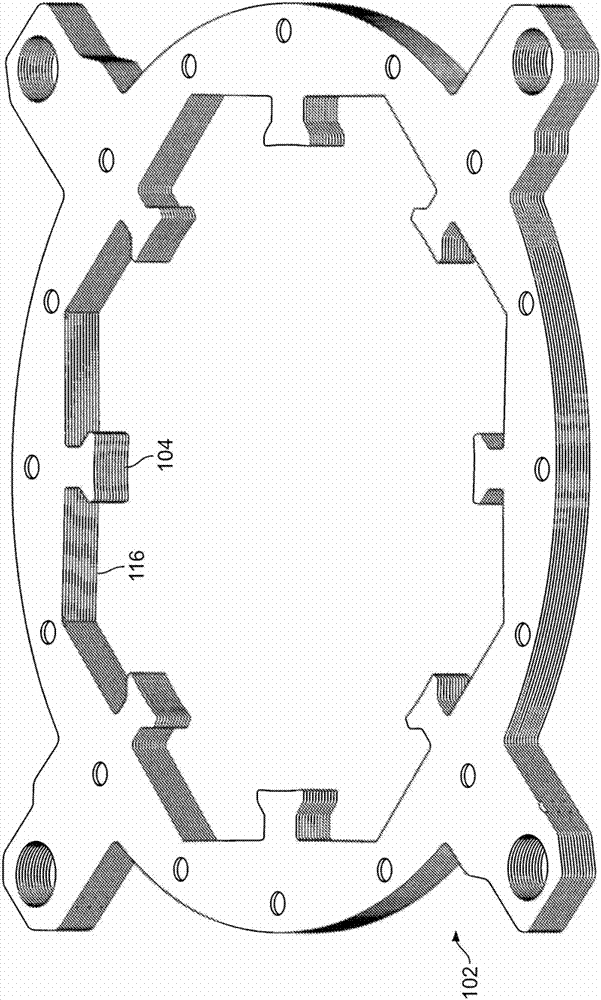

[0038] Referring now to the accompanying drawings, figure 1 A stator 100 is shown with a coil structure 106 mounted thereon according to the invention. The stator 100 comprises a magnetic core 102 on which are arranged eight teeth 104 also referred to as poles or flux guiding elements. A coil structure 106 is mounted on the magnetic core 102 such that the teeth 104 extend through the opening 108 at the coil structure 106 disposed around the opening 108, the coil structure 106 comprising a coil of wire wound or a flat conductive trace integrated into a printed circuit board. The wire 110 , which is here in particular formed, is wound helically around the opening and thus around the tooth 104 .

[0039] In the illustrated embodiment, the flat conductive traces 110 are shaped to form a conductive winding around each tooth 104 . The flat conductive trace 110 is fabricated on a flexible electrically insulating carrier 112, as from figure 1 obtainable. When the stator 100 with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap