Fully-automatic ring making machine special for processing brazing alloy material and processing method thereof

A brazing alloy, fully automatic technology, applied in the direction of wire material processing, manufacturing rings by wire, application, etc., can solve the problems of slow processing and molding speed, short service life of heaters, impact, etc., to achieve reasonable structural design and good processing quality , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

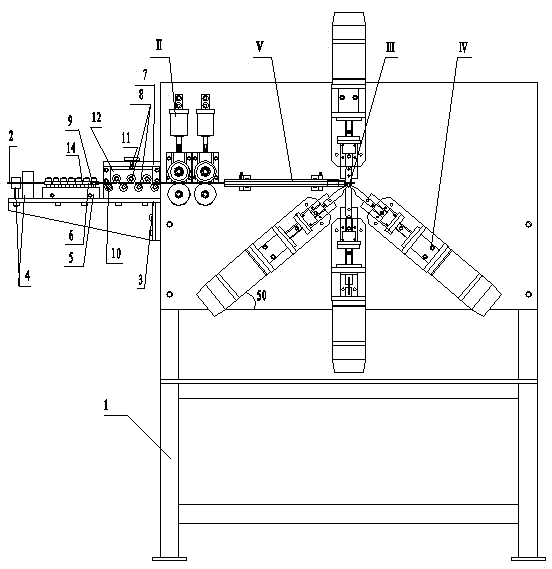

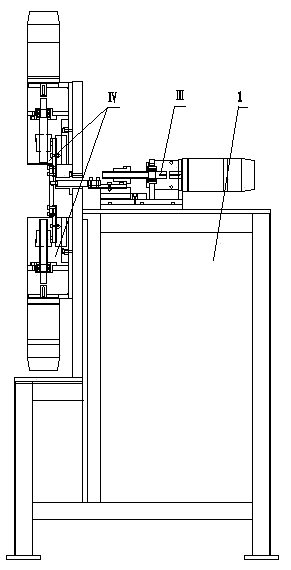

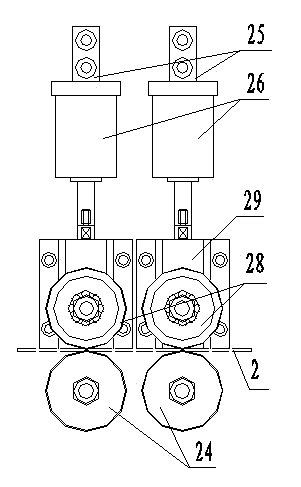

[0032] see Figure 1 to Figure 15 , the embodiment of the present invention is provided with a straightening device I, a traction device II, a mandrel device III, a multi-angle forming device IV, a heater V and a PLC controller, and the PLC controller controls the traction device II to carry out continuous processing of raw materials 2 Traction, so that the processed raw material 2 passes through the straightening device I under the traction at an appropriate speed to make the brazing alloy wire-shaped material (processed raw material 2) longitudinally in an orderly manner (relative to figure 1 The up and down direction, the same below) and the horizontal direction (relative to figure 1 The front and rear directions, the same below) are straightened, and then heated by the heater Ⅴ and then transported to the core mold device Ⅲ and the multi-angle forming device Ⅳ; the PLC controller controls the heater Ⅴ to heat the processed raw material 2 to make it reach the optimum Proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com