Feeding and conveying systems for conveying jigs and heat treatment industrial furnaces

A technology for fixtures and transmission direction, which is applied in the direction of thin material processing, lighting and heating equipment, furnaces, etc. It can solve the problems of difficult tension control, complex structure of transmission fixtures, and uninterrupted transmission, so as to reduce the difficulty of control and realize intermittent transmission. The effect of transmission and simplification of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

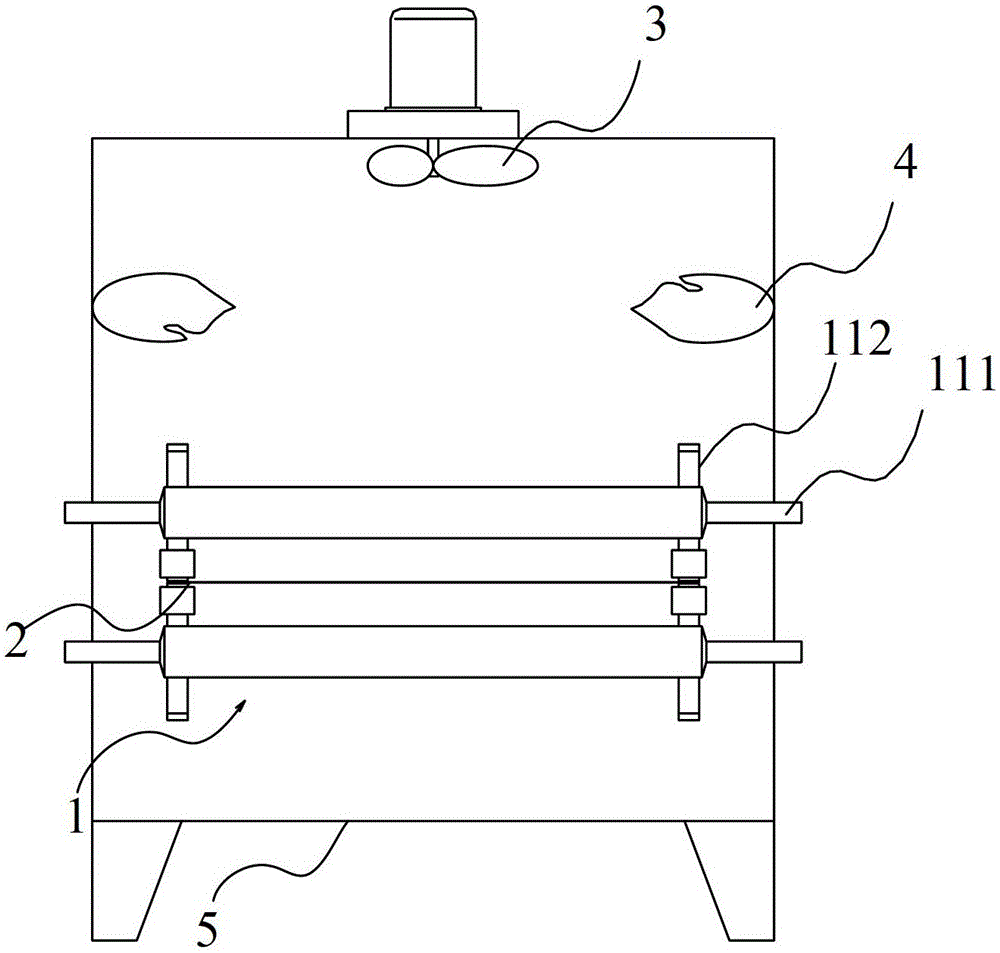

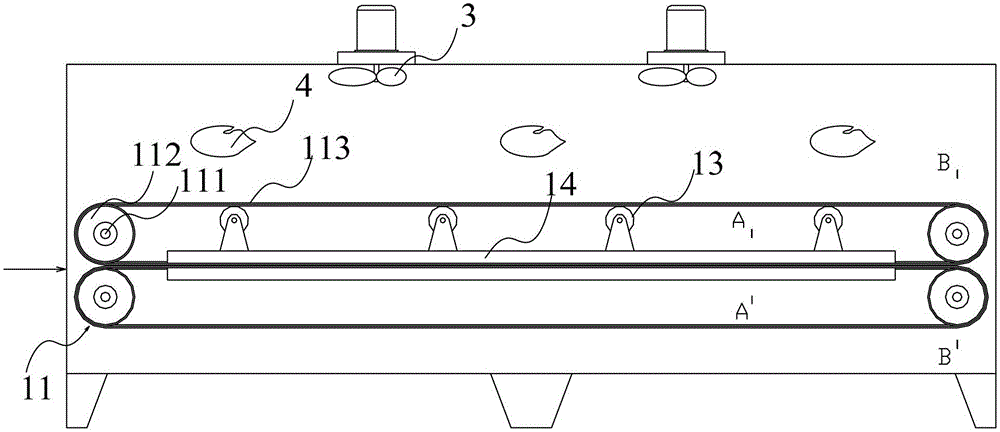

[0031] Such as figure 1 As shown, this embodiment includes a conveying device 1 , a workpiece 2 , a circulating fan 3 , a heating device 4 , and a furnace 5 .

[0032] Such as figure 2 As shown, the transmission device 1 includes two groups of sprocket mechanisms 11 up and down, and each sprocket mechanism 11 includes two chains 113 arranged on both sides. The chain drive has many advantages: no elastic sliding and slipping phenomenon, average transmission ratio Accurate, reliable, high efficiency; large transmission power, strong overload capacity, small transmission size under the same working conditions; small tension required, small pressure on the shaft; can be used in high temperature, humidity, dusty, Work in harsh environments such as pollution.

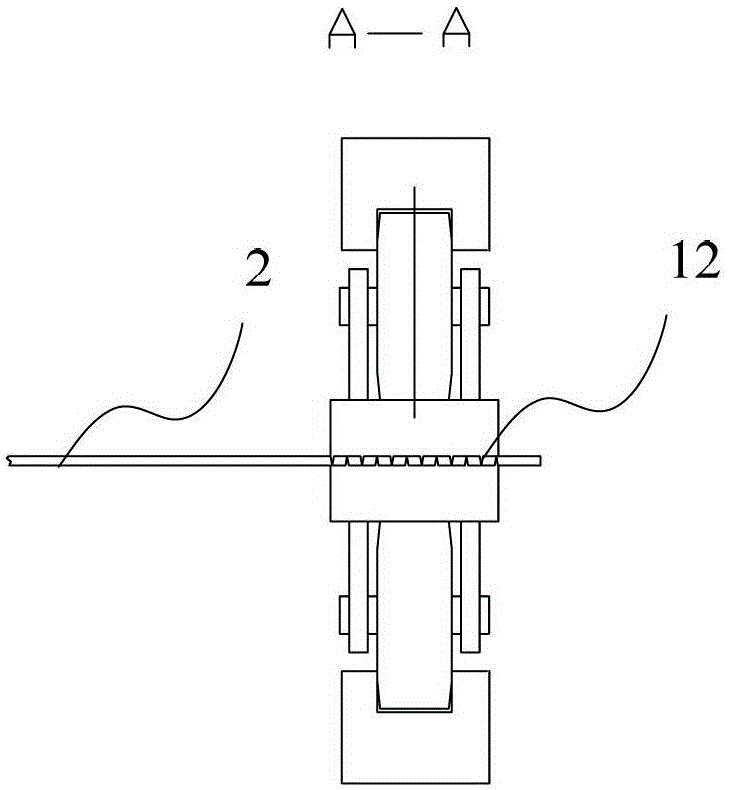

[0033] Such as image 3 or Figure 4 As shown, the clamp 12 is used to clamp the workpiece 2 . Clamp 12 is connected on the 11 chains 113 of sprocket mechanism, and under the drive of sprocket mechanism 11, chain 113 to...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that, in this embodiment, there is only one set of sprocket mechanism 11, and such arrangement can further simplify the mechanism. Correspondingly, this embodiment adopts such as Figure 6 Fixture 12 shown. Fixture 12 is a plurality of needle-nose pliers, each of which includes a jaw for clamping the workpiece, and a handle for controlling the opening and closing of the jaw, each of which is connected to a chain 113 fixed inside. In this way, the clamp 12 can clamp the workpiece 2 by itself, without the need to clamp the workpiece 2 under the clamping of the upper and lower chains 113 . The other parts of this embodiment are all the same as in Embodiment 1.

Embodiment 3

[0044] The difference between this embodiment and Embodiment 1 is that in this embodiment, the feeding and conveying system of the heat treatment industrial furnace includes two sets of conveying fixtures, such as Figure 7As shown, in this way, the relay transfer of the workpiece can be realized when the length of the path is long. The other parts of this embodiment are all the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com