Recovery and treatment equipment and process of waste diluted phosphoric acid containing metal salt

A technology for recycling and processing metal salts, applied in the direction of phosphoric acid, phosphorus oxyacids, etc., can solve problems such as waste of resources, pollution of the environment, and secondary pollution of sludge, and achieve saving of recycling costs, no secondary pollution, and high economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

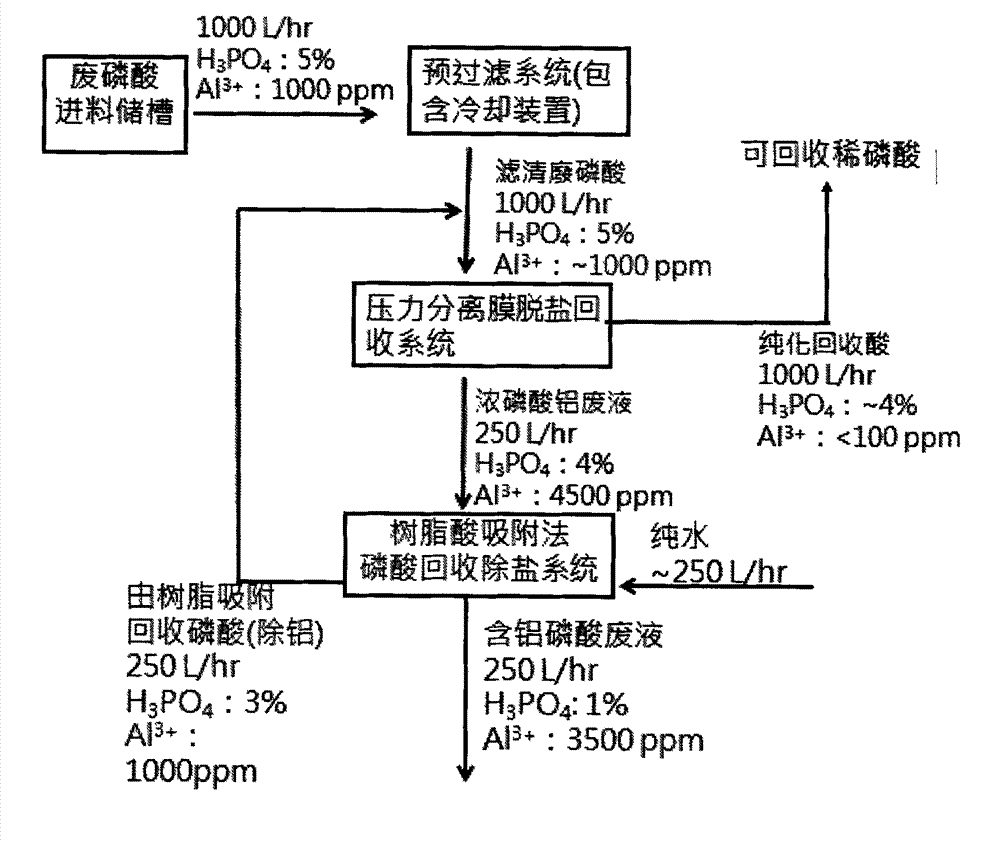

[0025] In this embodiment, aluminum-containing waste phosphoric acid with a mass concentration of phosphoric acid of about 5% and a mass concentration of aluminum ions of 1000 ppm is used as the waste liquid to be treated, and the device of the present invention is used to recover dilute phosphoric acid from the waste liquid. see figure 1 , the specific process is as follows:

[0026] (1), the aluminum-containing waste dilute phosphoric acid solution (H 3 PO 4 : 5%; Al 3+ : 1000ppm) is sent to the pre-filtration system at a flow rate of 1000L / hr for processing. The pre-filtration system includes a backwash filter device, which is composed of backwashable filter cloth or PE sintered filter element filter and security filter arranged in series or in parallel (depending on specific needs). It is mainly to filter out solid or colloidal particles in the waste dilute phosphoric acid solution to avoid blocking other filtration equipment such as separation membranes and adsorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com