Electroplating equipment

A technology of electroplating equipment and electroplating tank, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of high production cost, physical and mental health hazards of employees, unstable product quality, etc. The effect of improving the environment and prolonging the treatment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

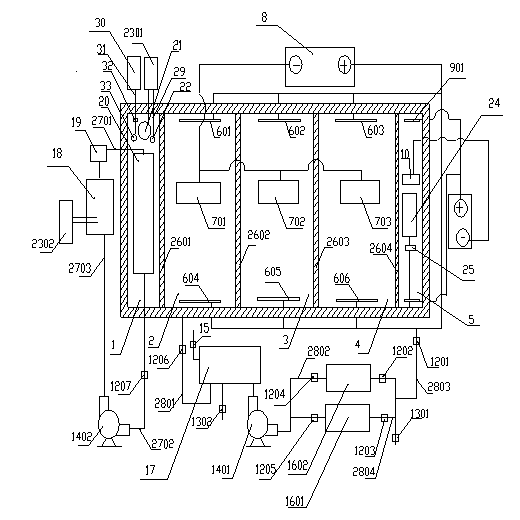

[0052] An example of an electroplating equipment with three single electroplating tanks is described in detail:

[0053] Such as figure 1 As shown, a kind of electroplating equipment consists of electroplating tank, anode (601-606), cathode (workpiece 701-703), electroplating solution, circulating filtration system, electric heating system, automatic additive supply system, water bath circulation heating center, automatic purification System and electroplating rectifier power supply (8).

[0054] A kind of electroplating equipment, the electroplating tank is composed of heating tank (1), single electroplating tank N=3 [(2)(3)(4)] and purification tank (5); electroplating single tank (2)(3) (4) The heating tank (1) and the purification tank (5) are separated from each other by partitions (2601-2604), and communicate with each other as a whole through the solution inlet and outlet.

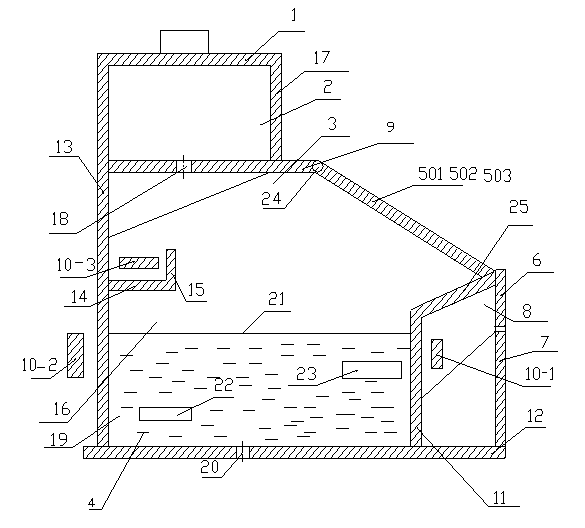

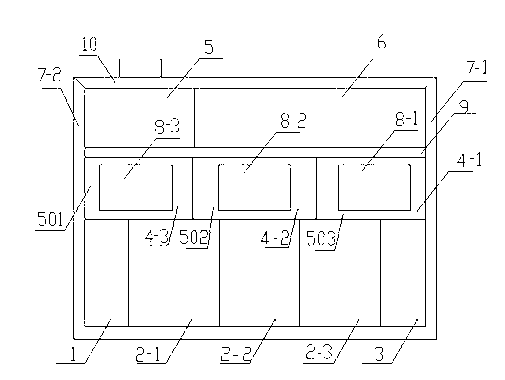

[0055] Such as figure 2 , image 3 As shown, an electroplating equipment is designed with multiple c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com