Method for regulating luminescence characteristic of rare earth noctilucent fiber

A technology of luminous fiber and luminescent properties, which is applied in the field of textile technology and optics, can solve the problems of high burning temperature, limited range of pigment selection, and high heat resistance requirements of inorganic transparent pigments, and achieve low heat resistance and easy operation , the effect of easy adjustment of the level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

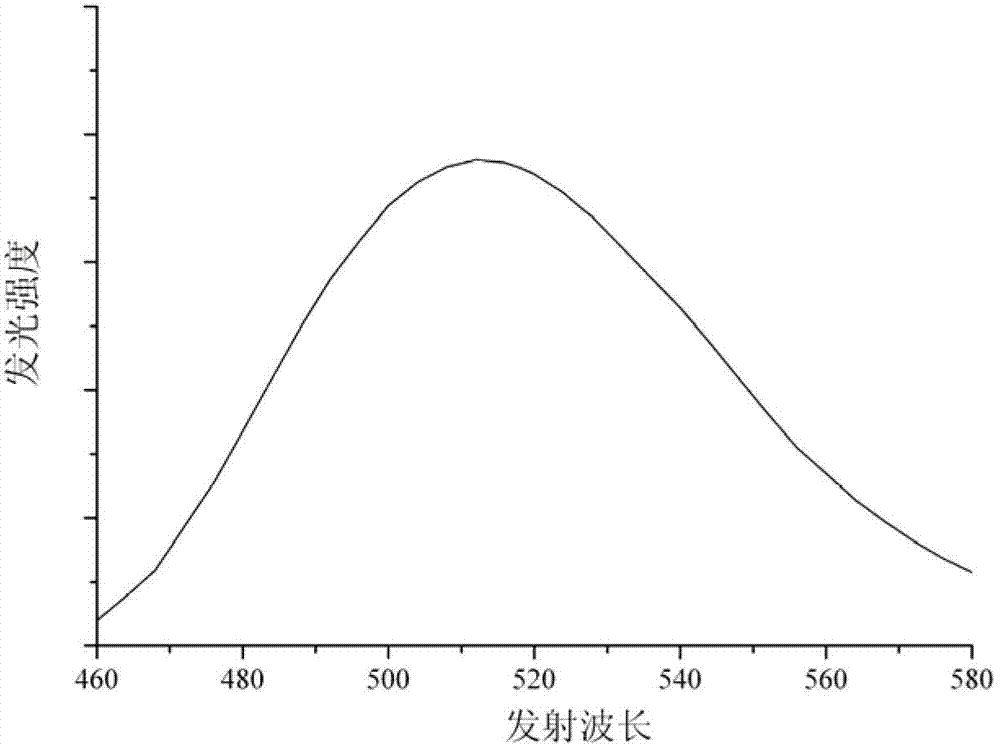

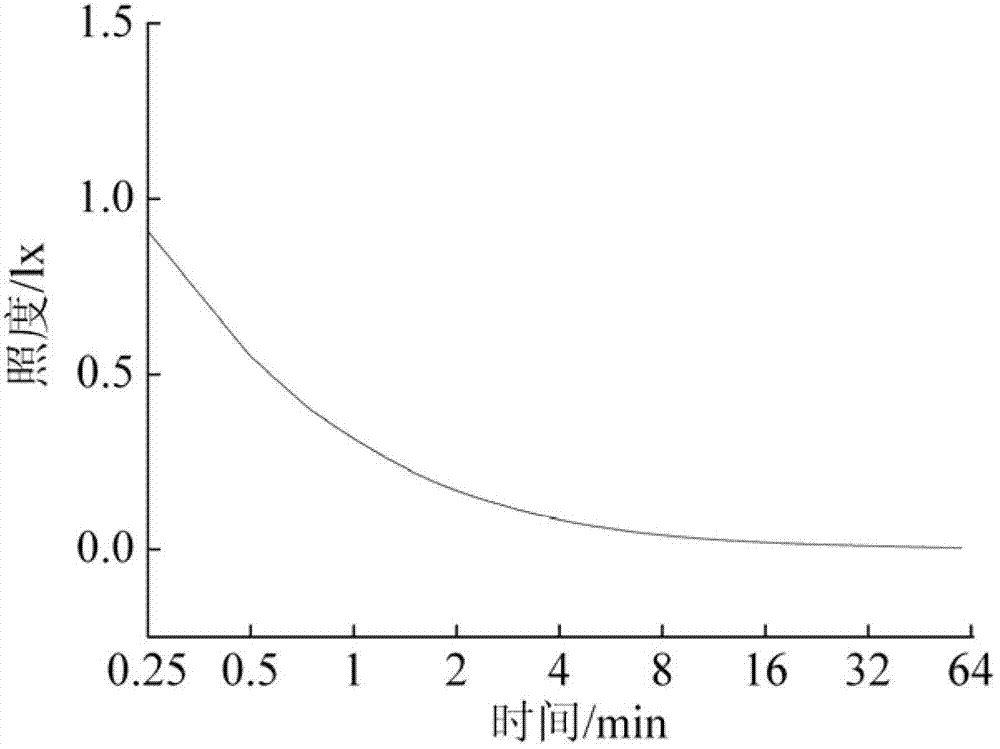

[0018] Take 5 parts of rare earth strontium aluminate long afterglow luminous material, 94.85 parts of PET polymer chips, add 0.15 parts of cobalt violet (PV-514), mix at 900r / min, melt and granulate at 265°C, dry at 105°C, Melt spinning at 290°C to obtain rare earth luminous fiber with adjusted luminous properties. The luminous wavelength of the tested fiber is 512nm, and the afterglow initial test brightness is 0.876Lx. The emission spectrum and afterglow curve are as attached figure 1 , 2 shown.

Embodiment 2

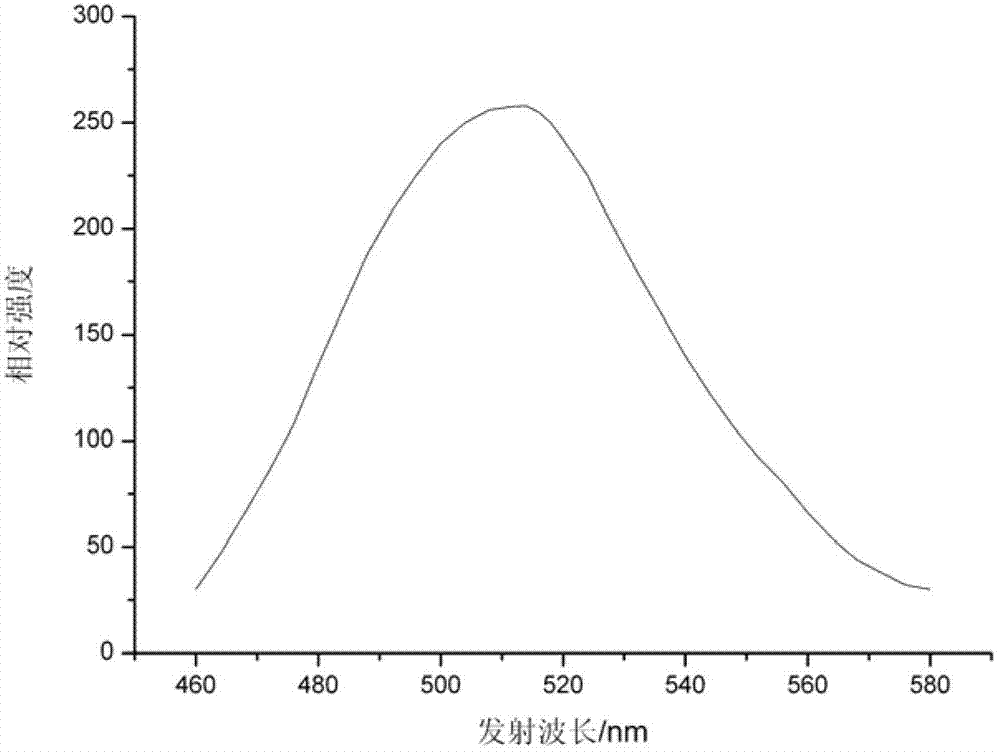

[0020] Take 5 parts of rare earth strontium aluminate long afterglow luminous material, 94.85 parts of PET polymer chips, add 0.15 parts of cobalt chromium blue (PBl-536), mix at 900r / min, then melt and granulate at 265°C, and dry at 105°C , Melt spinning at 290°C to obtain rare earth luminous fiber with adjusted luminous properties. The luminous wavelength of the tested fiber is 514nm, and the afterglow initial test brightness is 0.985Lx. The emission spectrum and afterglow curve are as attached image 3 , 4 shown.

Embodiment 3

[0022] Take 8 parts of alkaline earth silicate long-lasting luminescent material, 90 parts of PET polymer slices, add 0.01 part of inorganic composite pigment cobalt green, mix at 700r / min, then melt and granulate at 285°C, dry at 100°C, and then dry at 300°C Melt spinning to obtain rare earth luminous fiber with adjusted luminous properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com