On-line real-time monitoring method and device for failure of hydraulic motor of large-sized plate bending roll

A hydraulic motor, real-time monitoring technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc., can solve the problems of equipment output power reduction, becoming load, transmission component damage, etc., to achieve reliability And the effect of life improvement, reasonable design, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

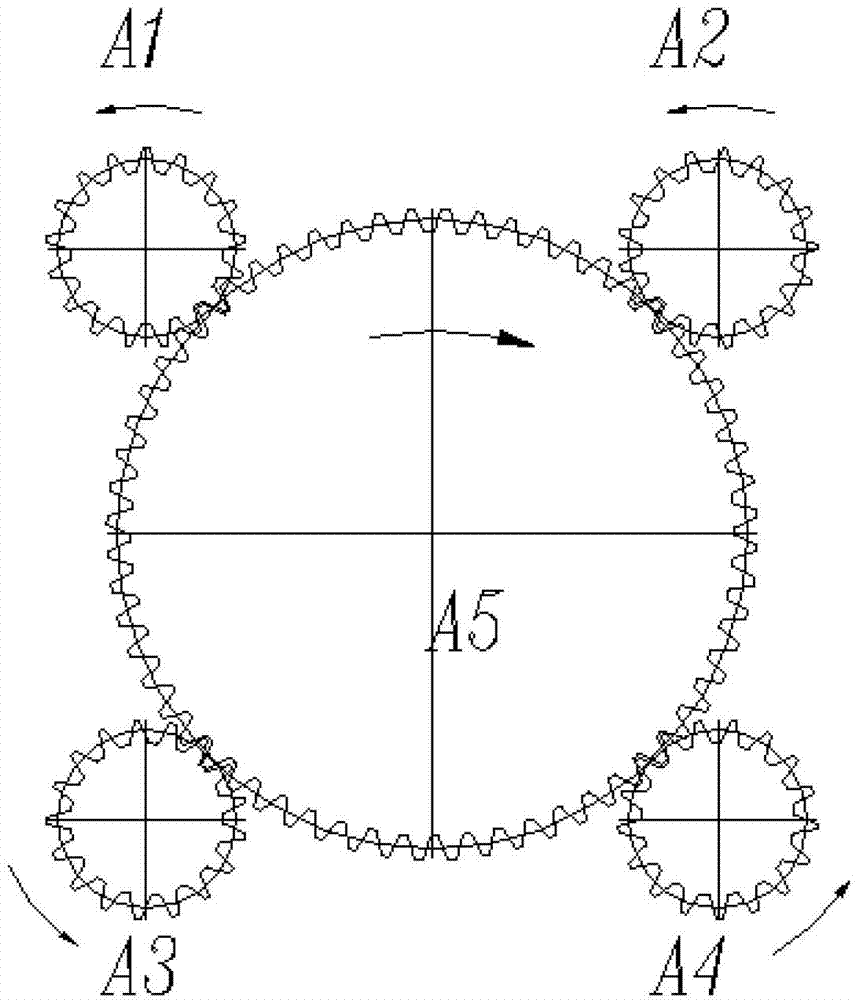

[0018] figure 1 Shown is a schematic diagram of the structure when four hydraulic motors simultaneously drive a rotating device. Four driving gears are respectively A1, A2, A3 and A4 installed on the output shafts of the four hydraulic motors. Four driving gears A1, A2, A3, A4 drive a driven gear A5 at the same time. This is a common and typical situation where multiple hydraulic motors simultaneously drive a rotating part. The present invention takes this example as an illustration, and its protection scope is not limited by the specific number of hydraulic motors.

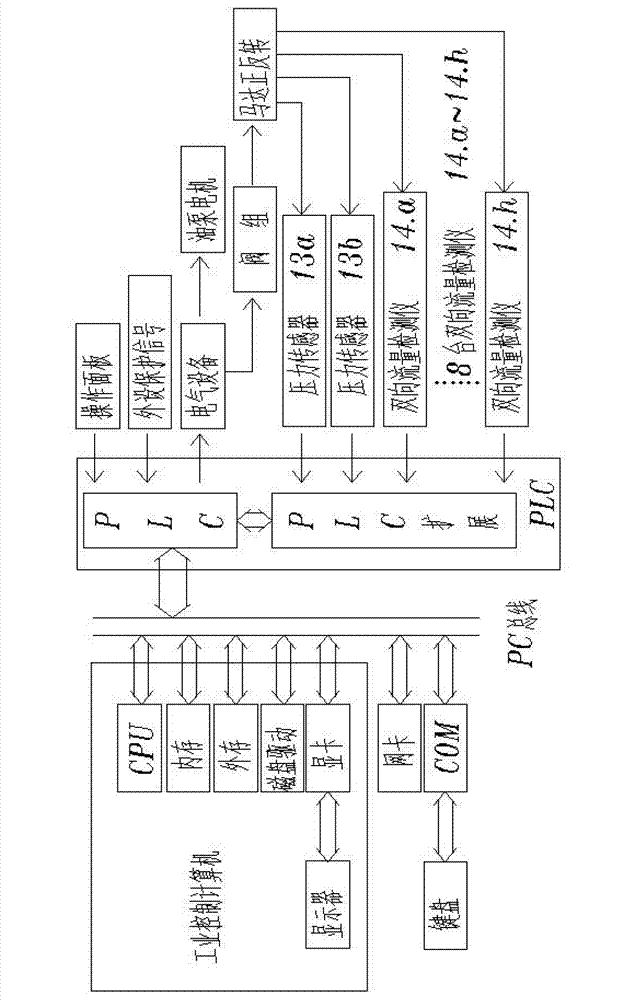

[0019] figure 2 It is a structural diagram of industrial computer and PLC communication sampling in the present invention. This figure introduces that after the pressure and flow signals are collected and processed by PLC, they are uploaded to the upper computer—the industrial computer through communication. At the same time, the industrial computer also transmits the parameters set by the system to the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com