Glass fiber reinforced plastic trousers leg three-way pipe and manufacturing method thereof

A production method and technology of glass fiber reinforced plastics, applied in the direction of tubular objects, pipeline connection arrangements, and other household appliances, can solve the problems of large fluid pressure head loss, unfavorable fluid transmission, and large resistance of cement pipes, etc., to achieve small fluid pressure head loss, Excellent corrosion resistance and low flow resistance

Inactive Publication Date: 2013-04-10

JIANGXI KEDE NEW MATERIALS CO LTD

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For the selection of bifurcated pipeline products, cement and steel pipe products are generally used for pipeline transmission, but cement pipes are not conducive to fluid transmission due to their large resistance, large fluid pressure head loss or large pressure drop; and steel pipes need to manufacture molds, which are costly and Poor corrosion resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

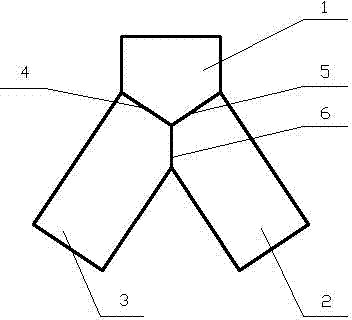

The invention discloses a glass fiber reinforced plastic trousers leg three-way pipe, which comprises a trousers waist short pipe having a trousers simulation structure, and two sections of trousers leg short pipes, wherein an included angle between the central axes of the two sections of trousers leg short pipes is any value of 0-180 degrees; the trousers waist short pipe consists of a lining layer, a structural layer and an outer protective layer form inside to outside; and each trousers leg short pipe consists of a lining layer, a structural layer and an outer protective layer form inside to outside. A splicing manufacturing method comprises the following steps of: (1) manufacturing a glass fiber reinforced plastic-wound trousers waist short pipe and glass fiber reinforced plastic-wound trousers leg short pipes respectively; (2) splicing into a trousers leg three-way pipe; (3) seaming internally; (4) integrally reinforcing from the outside; and (5) forming outer protective layers. The glass fiber reinforced plastic trousers leg three-way pipe is lower in cost than steel pipe products of the same type and specification, and has all characteristics of glass fiber reinforced plastic products. The lining layers of the glass fiber reinforced plastic trousers leg three-way pipe are smooth on the surfaces and have small flowing resistance, so that the fluid head loss is small or the pressure drop is small. The glass fiber reinforced plastic trousers leg three-way pipe disclosed by the invention can be taken as a shunting connecting pipe for any glass fiber reinforced plastic pipeline branch of any angle and any caliber.

Description

technical field [0001] The invention relates to pipe fittings, in particular to a fiberglass trouser leg tee pipe and a manufacturing method thereof. Background technique In the construction of modern water supply and drainage and chemical engineering, some complex pipeline engineering constructions are often encountered, especially the pipelines with multi-forked road layout, which often need to use three-way pipe fittings. For the selection of bifurcated pipeline products, cement and steel pipe products are generally used for pipeline transmission, but cement pipes are not conducive to fluid transmission due to their large resistance, large fluid pressure head loss or large pressure drop; and steel pipes need to manufacture molds, which are costly and Corrosion resistance is poor. Contents of the invention A technical problem to be solved by the present invention is to make up for the defects of the above-mentioned prior art, and to provide a fiberglass trouser leg t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16L47/32B29D23/00

Inventor 奉玉贞曹昌龙刘申武

Owner JIANGXI KEDE NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com