A closed explosion-proof tank

An explosion-proof tank and tank body technology, applied in blasting and other directions, can solve the problems of structural design and complex operation, and achieve the effects of simple structure, small weight and small volume of the tank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to illustrate the technical solution of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings.

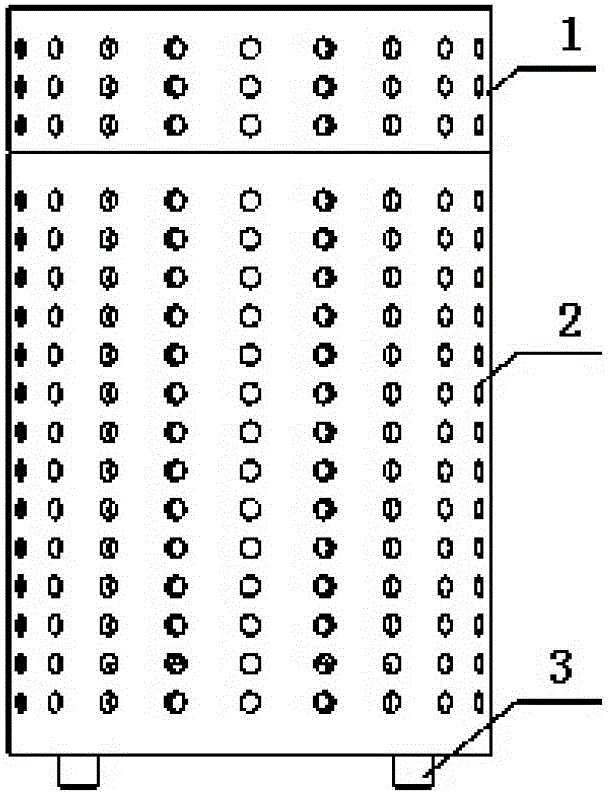

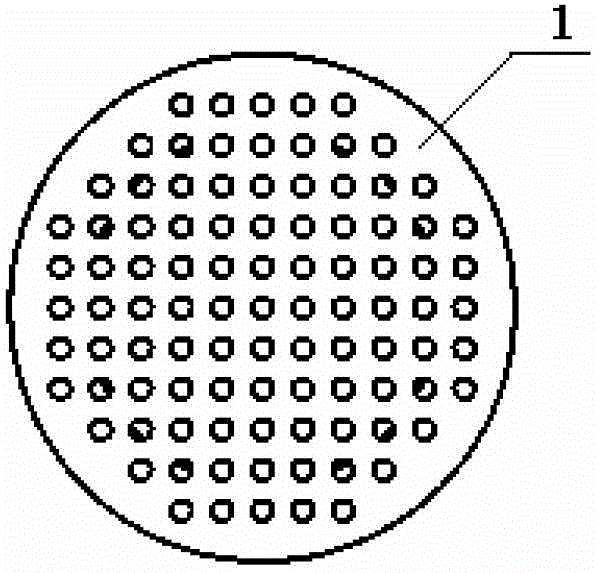

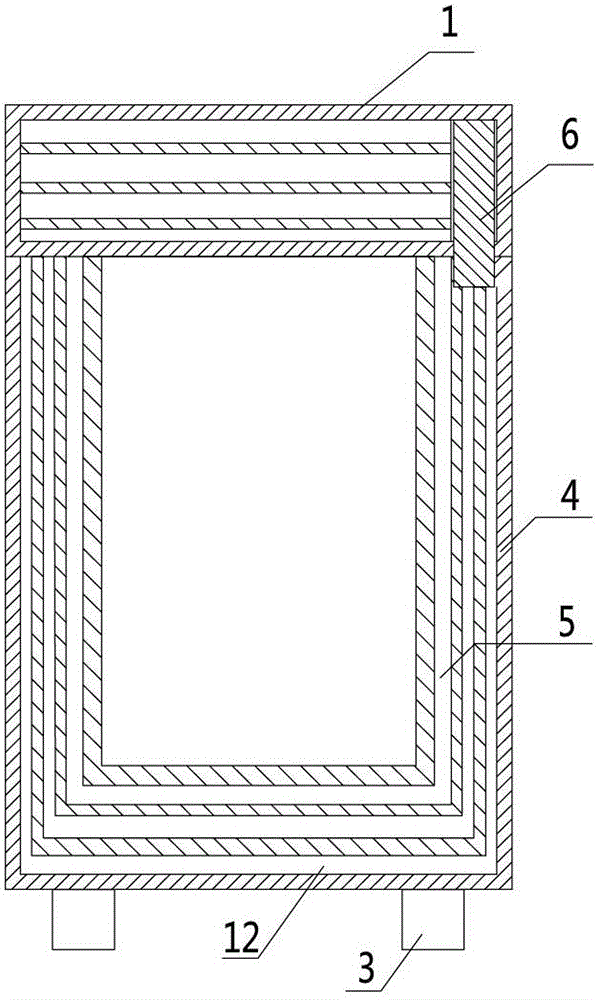

[0029] Such as figure 1 , figure 2 , image 3 As shown, the closed explosion-proof tank of the present invention consists of a top cover 1, a tank body 2 and casters 3. The tank body 2, the tank body bottom and the top cover 1 of the closed explosion-proof tank are all porous composite structures, composed of multi-layer porous steel plates 4 and porous inorganic non-metallic energy-absorbing materials 5 and metal wire wadding filled between the porous steel plates 4. Shaped energy-absorbing material 12 is compounded. The multi-layer porous steel plate 4 is composed of 2-6 layers of porous steel plate 4, the thickness of the porous steel plate 4 is uniform or thickened layer by layer from inside to outside, and the thickness is in the range of 1 mm to 6 mm. Each layer of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com