Wide test angle ArF laser polarization optics thin film element spectrum test device

A technology of polarization optics and thin-film components, which is applied in the direction of testing optical properties, etc., can solve the problems of limited measurement accuracy of polarization characteristics, inability to meet the spectral characteristics of optical components, and inability to accurately evaluate polarization spectral characteristics, etc., to achieve the effect of suppressing light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

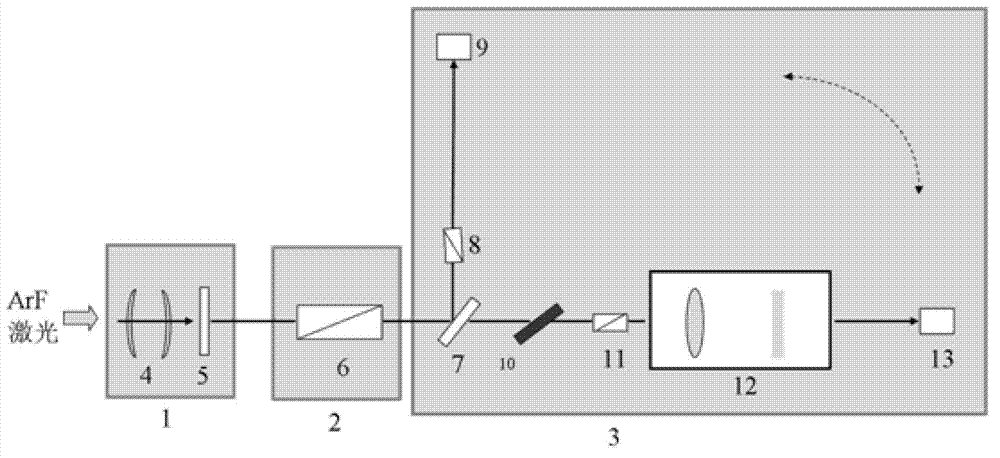

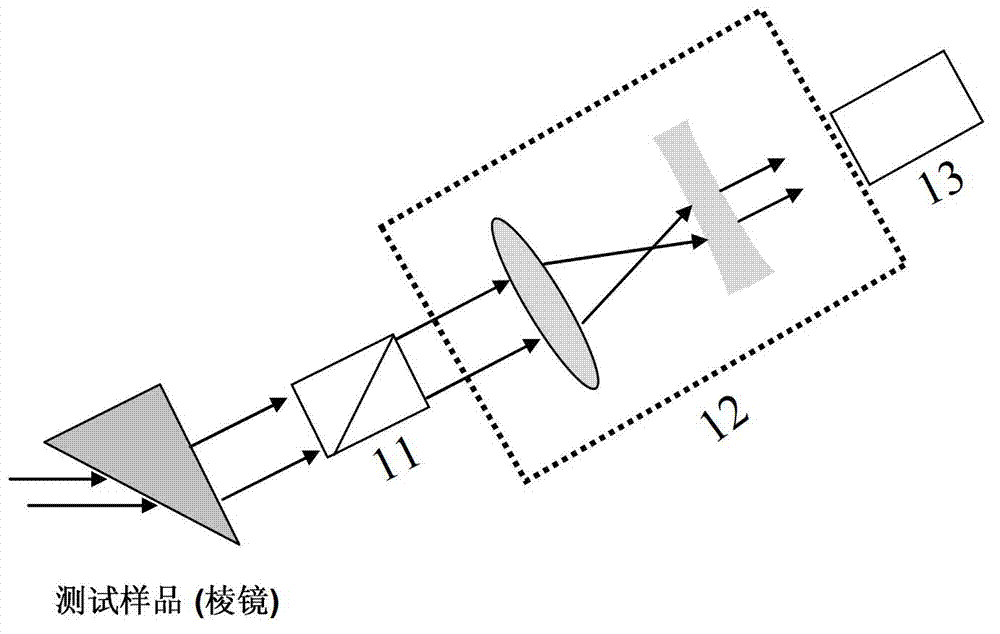

[0016] Specific embodiment 1: large test angle ArF laser polarization optical thin film element spectral test:

[0017] ArF laser optical thin film angle scattering measuring device of the present invention is before formal measurement, in order to avoid the absorption that oxygen and water vapor in the air produce below 200nm, the side wall of the first vacuum chamber 1 is set to pass into N 2 High-purity N is introduced into the connecting pipeline of the gas 2 Gas, fill the entire cavity pipeline, and install the N from the end of the third rectangular vacuum cavity 3 cavity 2 Gas exhaust line, discharge N 2 Gas, high-purity N is introduced into the whole chamber 2 After more than 30 minutes, the sample scan will not start until the 100% line measurement result of the test system is completely stable.

[0018] According to the size of the optical element, set the size of the iris diaphragm in the rectangular vacuum chamber 1, set the polarization state of the polarizer 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com