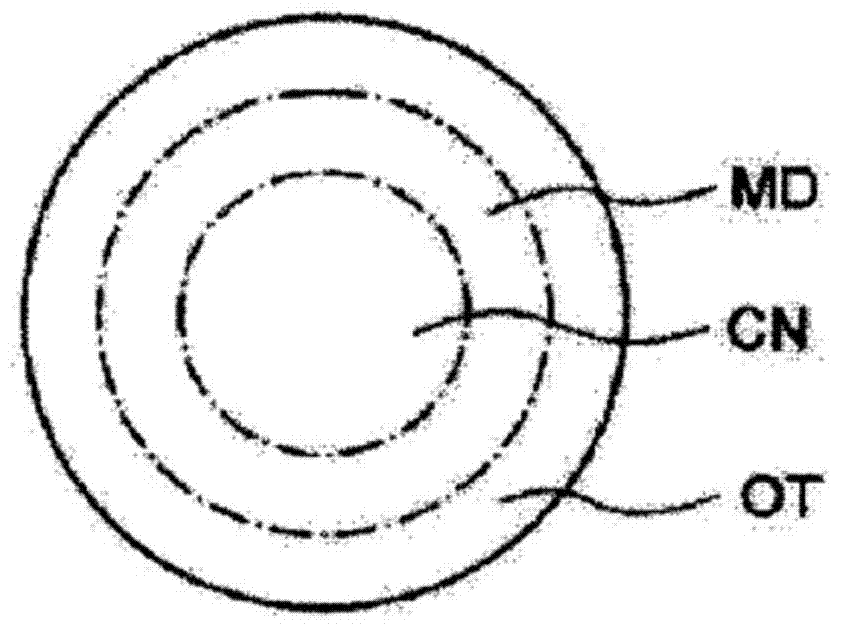

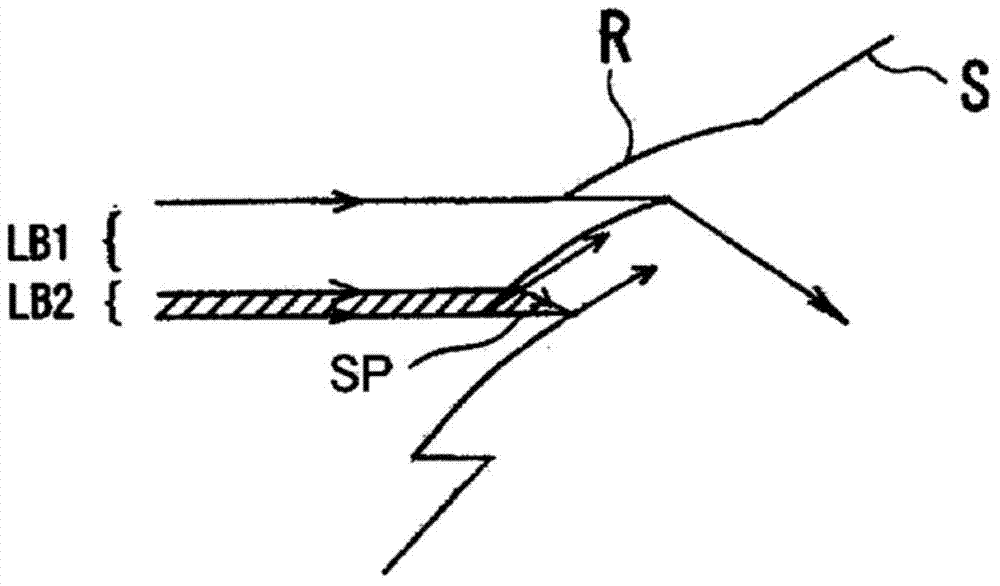

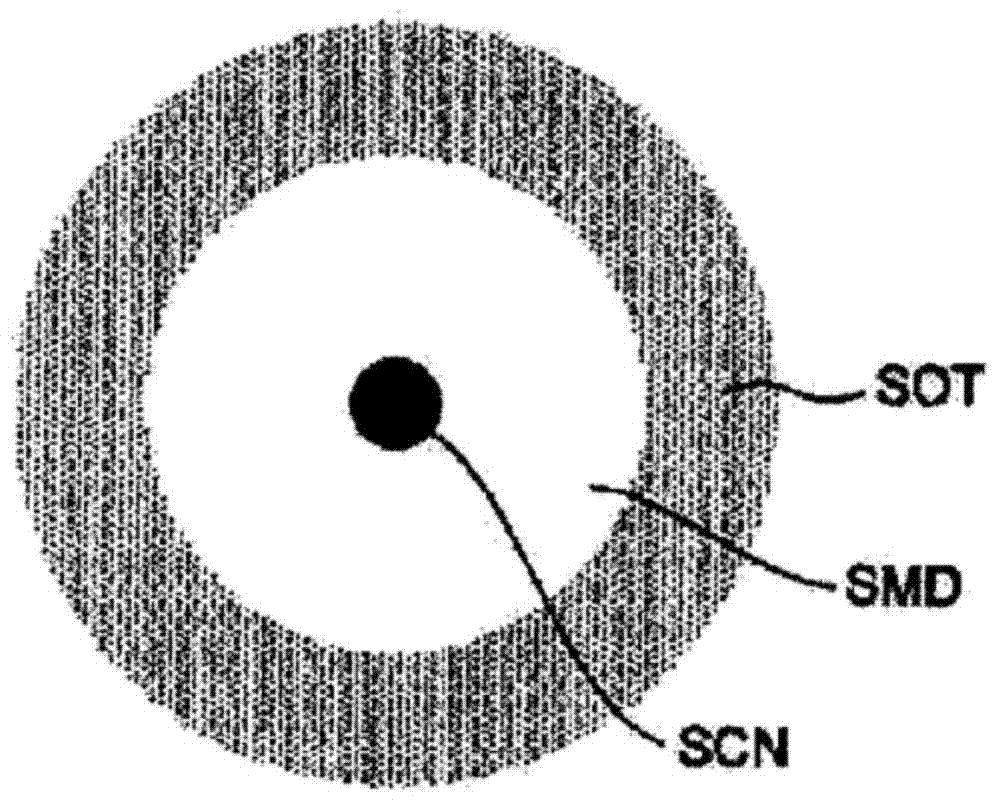

Objective lens and optical pickup device

A technology of optical pickup device and objective lens, which is applied in the recording/reproducing, data recording, instrument and other directions by optical methods, can solve the problems of increased cost, disadvantageous miniaturization, etc. The effect of large spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0333] Table 1 shows the lens data of Example 1. The objective lens of embodiment 1 is a plastic monolithic lens, the steps of the first basic structure and the third basic structure face the direction opposite to the optical axis, and the steps of the second basic structure, the fourth basic structure and the fifth basic structure face the optical axis The direction of the axis. In addition, in the first optical path difference imparting structure of Example 1, in the entire area of the central area, the second basic structure of the blazed diffraction structure of (2 / 1 / 1) is superimposed as (1 / 1 / 1) 1) The optical path difference imparting structure of the first basic structure of the blazed diffractive structure. The second optical path difference imparting structure is a fourth base structure that is a (1 / 1) blazed diffraction structure superimposed on the fourth base structure that is a (5 / 3) blazed diffraction structure in the entire middle region. The optical path di...

Embodiment 2

[0353] Table 2 shows the lens data of Example 2. The objective lens of embodiment 2 is a plastic monolithic lens, the steps of the first basic structure and the third basic structure are towards the direction opposite to the optical axis, and the steps of the second basic structure, the fourth basic structure and the fifth basic structure are towards the optical axis. The direction of the axis. In addition, in the first optical path difference providing structure of Example 2, in the entire area of the central area, the second basic structure of the blazed diffraction structure of (2 / 1 / 1) is superimposed as (1 / 1 / 1) 1) The optical path difference imparting structure of the first basic structure of the blazed diffractive structure. The second optical path difference imparting structure is a fourth base structure that is a (1 / 1) blazed diffraction structure superimposed on the fourth base structure that is a (5 / 3) blazed diffraction structure in the entire middle region. The ...

Embodiment 3

[0373] Table 3 shows the lens data of Example 3. The objective lens of embodiment 3 is a plastic monolithic lens, and the steps of the first basic structure and the third basic structure are towards the direction opposite to the optical axis, and the steps of the second basic structure, the fourth basic structure and the fifth basic structure are towards the optical axis. The direction of the axis. In addition, in the first optical path difference imparting structure of Example 3, in the entire area of the central area, the second basic structure of the blazed diffraction structure of (2 / 1 / 1) is superimposed as (1 / 1 / 1) 1) The optical path difference imparting structure of the first basic structure of the blazed diffractive structure. The second optical path difference imparting structure is a fourth base structure that is a (1 / 1) blazed diffraction structure superimposed on the fourth base structure that is a (7 / 4) blazed diffraction structure in the entire middle region. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com