Element analyzing system

A technology for elemental analysis and analysis components, which is applied in the direction of analyzing materials, material analysis by optical means, measuring devices, etc., which can solve the problem of low reliability of elemental measurement results, inability to obtain blank values of compressed gas, and inability to obtain blanks in elemental analysis systems. value and other issues to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

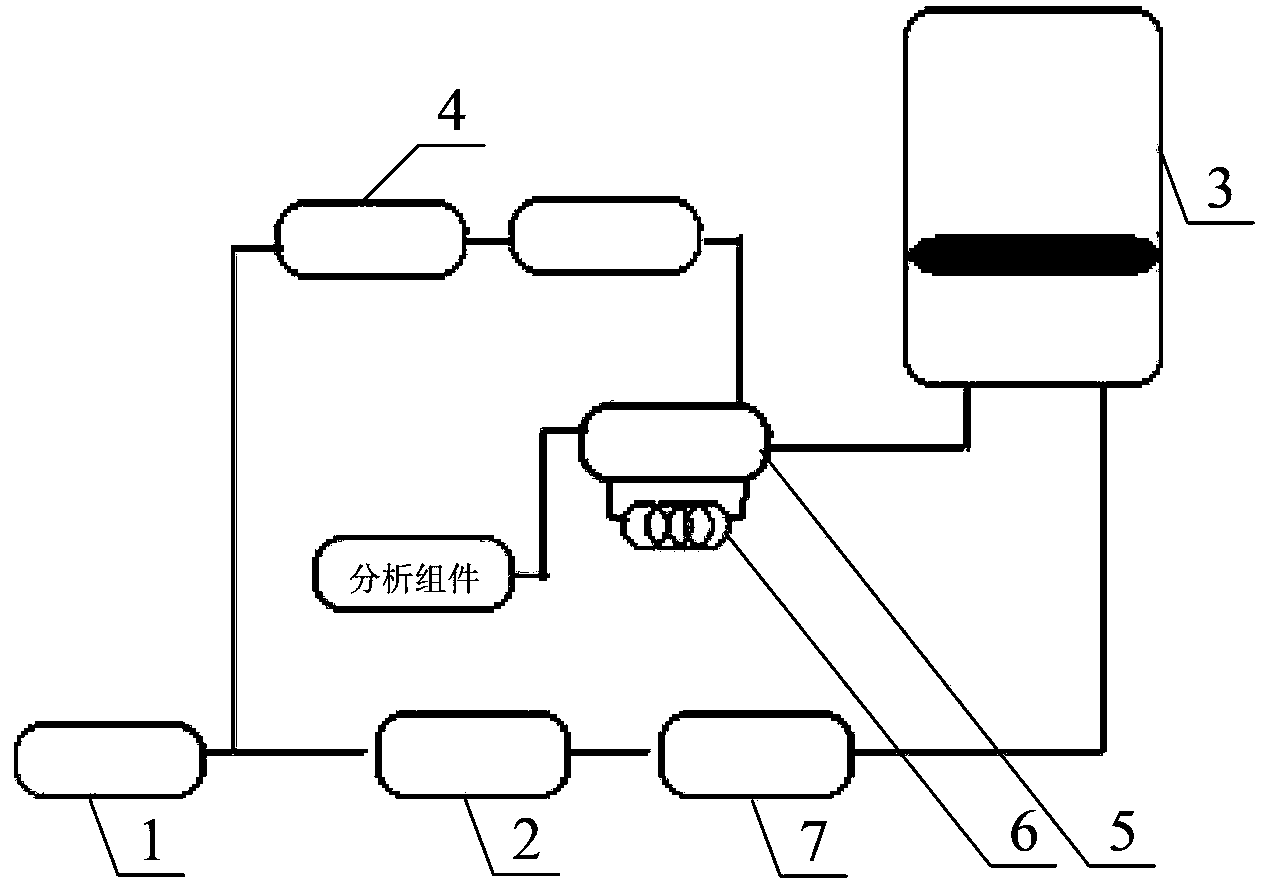

[0022] The core of the present invention is to provide an elemental analysis system. The elemental analysis system divides the combustion-supporting gas into two working paths, one of which is purified to obtain an accurate blank value, and the other path is involved in combustion to obtain a test voltage value. Through this structural design, The influence of water vapor and carbon dioxide gas in the combustion-supporting gas on the test results can be avoided, and the reliability of the element determination results is improved.

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] Please refer to figure 1 , figure 1 It is a schematic structural diagram of an elemental analysis system in an embodiment of the present invention.

[0025] The invention provides an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com