Non-destructive testing method for oxide accumulation state of inner wall of austenitic boiler steel tube of utility boiler

A technology for boiler steel pipes and power plant boilers, applied in the direction of material magnetic variables, etc., can solve problems such as detection signal exceeding the standard, outer wall oxidation, stainless steel pipe influence, etc., achieve high accuracy, tight time, and avoid the effects of blocking and bursting pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

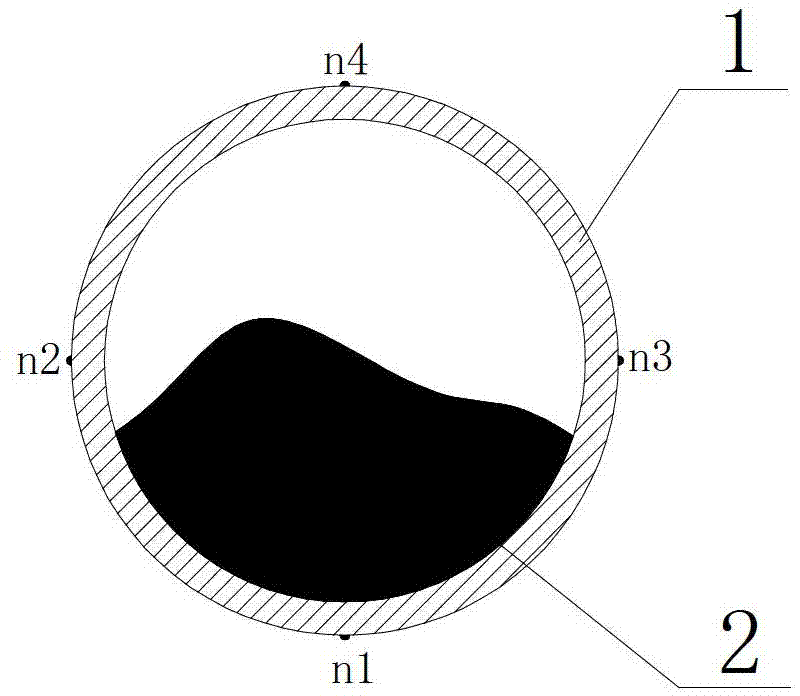

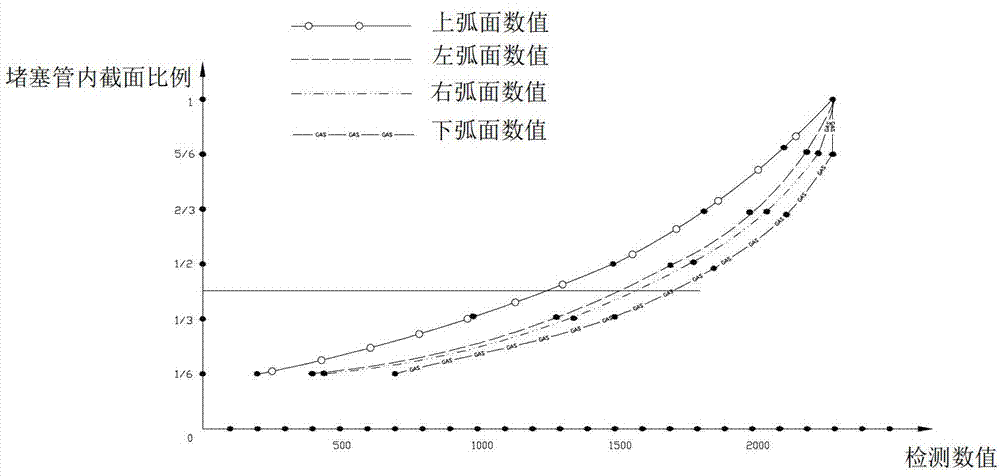

[0021] 1. Take a new tube with the same specifications as the high temperature heating surface of the boiler as sample tube 1. For example, the TP347H straight pipe with a typical commonly used specification of Φ45×7.8mm, and adding oxide 2 to block the 6 states of the cross-sectional area of the pipe respectively: 1 / 6, 1 / 3, 1 / 2, 2 / 3, 5 / 6, full full.

[0022] 2. Measure and record the initial value H0 of the magnetic intensity equivalent of the sample tube 1 with a measuring device using the principle of electromagnetic conversion. The measurement process is as follows:

[0023] (1) Clear the signal before the U-shaped probe touches the steel pipe;

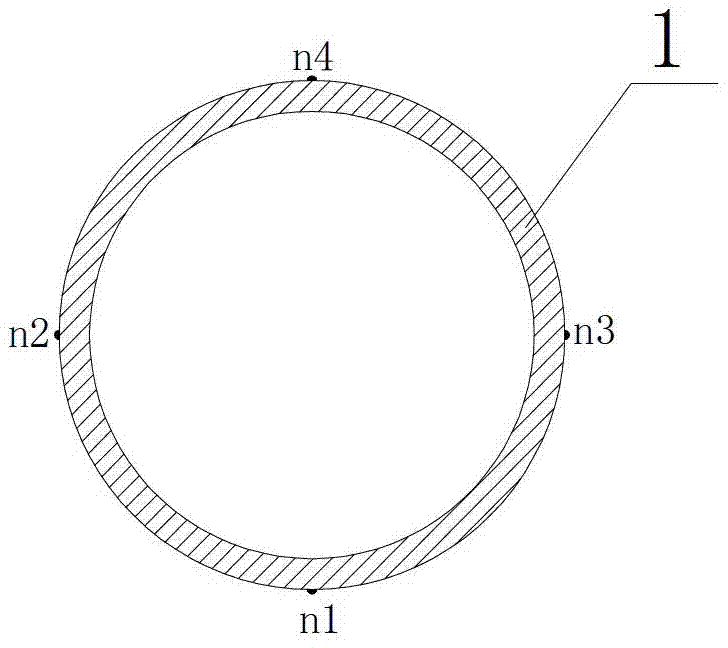

[0024] (2) Divide the sample tube into 4 equal parts (lower arc surface n1, left arc surface n2, right arc surface n3, upper arc surface n4) along the cross-sectional direction and mark them. The measurement points are as follows: figure 1 shown;

[0025] (3) The curved surface of the straight rod or U-shaped probe is in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com