Automatic ultrasonic detection equipment for weld defects of connecting pipe and safe end of pressure vessel of nuclear power station

A pressure vessel and automatic detection technology, which is applied in the field of nuclear detection systems, can solve problems such as the inability to meet the frequency of weld detection, increase the difficulty of operation and learning, and huge detection equipment, and achieve light weight, short detection cycle and short installation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and the application process.

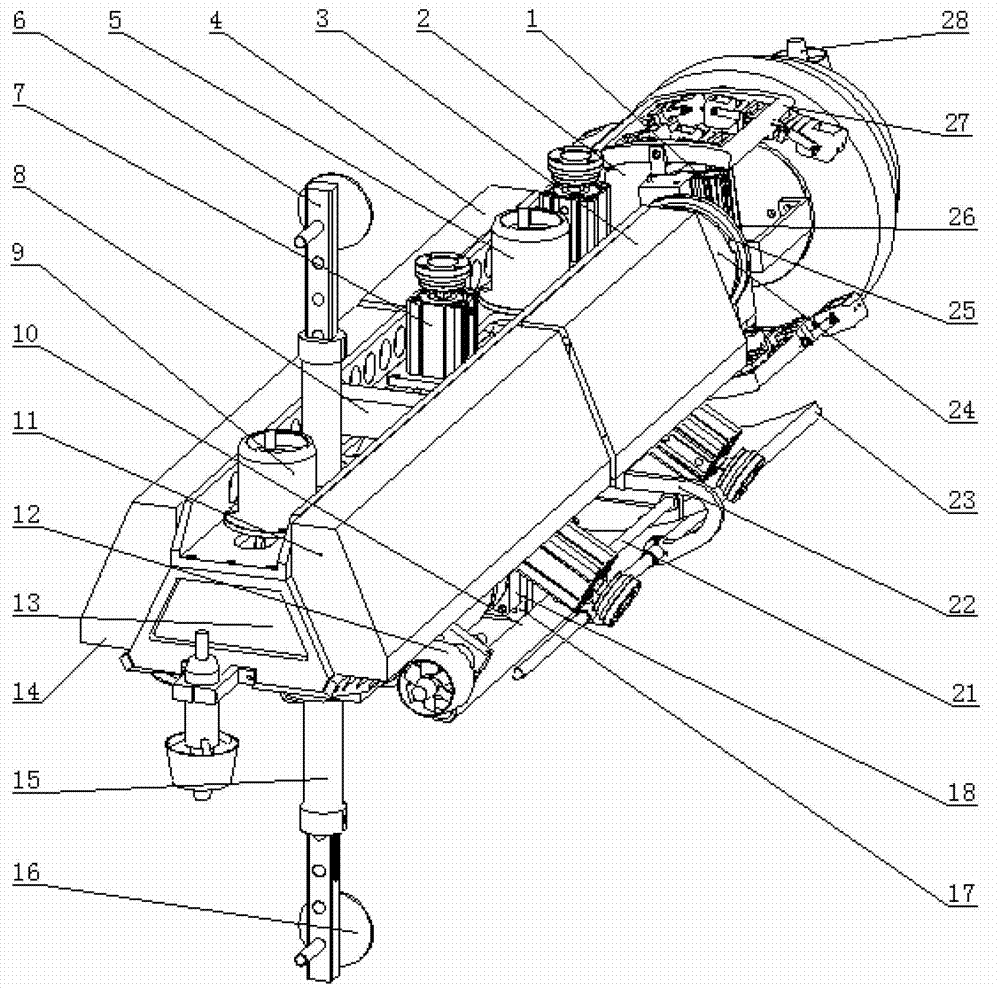

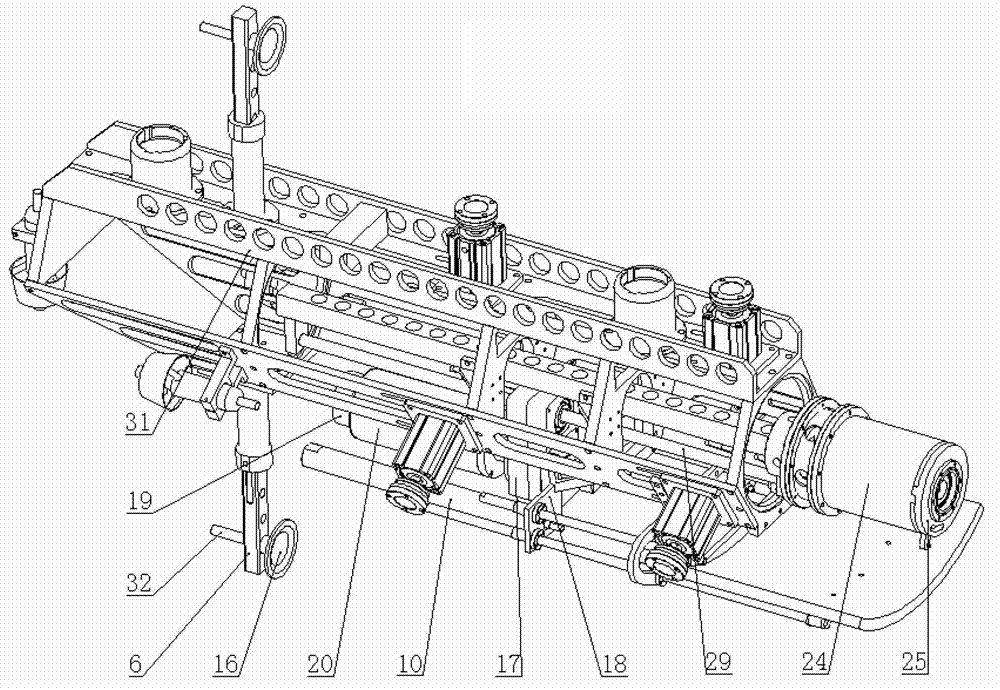

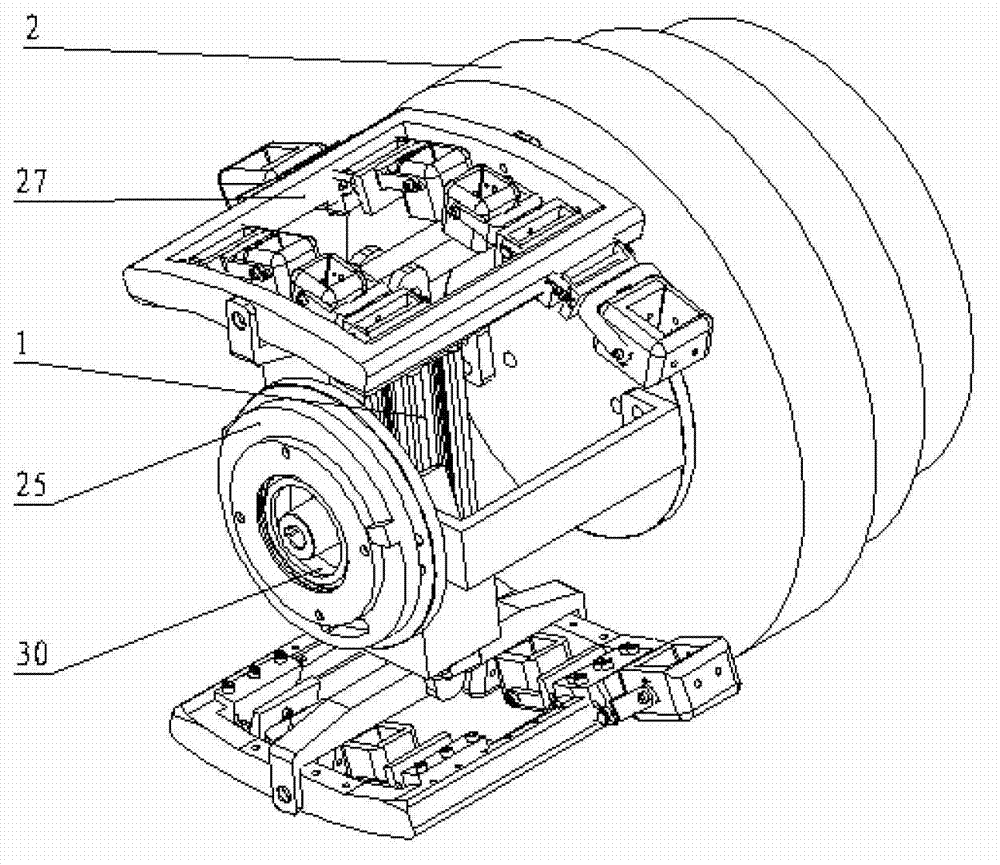

[0016] Such as figure 1 --- image 3 As shown, the detection device in the detection equipment is:

[0017] The buoyancy device that is made up of three head buoyancy blocks 2, the right front buoyancy block 3, the left front buoyancy block 4, the right rear buoyancy block 11, and the left rear buoyancy block 14. They are respectively installed on the head of the detection device and the front and rear of the left and right sides to increase the buoyancy of the detection device and make it suspended in the water, so as to facilitate the driving of the lifting propeller 28. All buoyancy blocks are composed of various small buoyancy blocks inside it. Reducing the number of buoyancy blocks can achieve the purpose of adjusting the buoyancy of the detection device;

[0018] Installed by the end effector cylinder 1, the axial limit adjustment r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap